Yep all electronic although the 8-pin module itself has a backup advance curve in it. With the distributor at TDC with the OEM 369 module atleast the timing bumps from TDC to like 8* @ 1,600 rpm then climbs to about 22* @ about 2,400 rpm.

I have had "discussions" with other folks on another forum, they swore that there was no advance curve built-into the 8-pin module. I had head that there was.

Good to have confirmation. I never got up the ambition to test it for myself.

Delco also offered other marine specific 8-pin modules with varying advance curves for their Voyager line of marine distributors.

So far as I know, there is only one marine module part number. I bought a Voyager conversion kit years ago for my 454 boat--this was not so long after they were discontinued. I had to piece my "kit" together from individual parts. There were various distributors (4, 6, and 8 cylinder) a few coils and spark plug wire sets (to fit the various engines) and some basic wire harnesses to plug into the coils and distributors; and a timing connector that has to be plugged in to set initial timing.

Flat tappet cams are ground from a steel blank and don't receive a hardening process. They harden during break-in, and sometimes they wipe out rather than break in.

I thought flat-tappet cams were flame-hardened on cast iron cores, which also accounted for the black oxide coating on the lobes. Perhaps I'm wrong; or the process has changed over time.

A roller cam may be ground on a cast-iron core (cheap cams) or on a steel core (more expensive, and requires a hardened (melonized) or very soft (brass or plastic) distributor gear. GM roller cams are steel, and thus are used with the melonized gear. A melonized gear can be used on an iron core, too.

There are steel cam cores that have had the rear portion--the gear on the back of the cam, and the rear cam journal--cut off and replaced with a pressed-on iron gear and rear journal. That's what I have on my boat engine. I think Lunati called it the "Everwear" option.

If your rockers are getting hot enough to harden, there's something seriously wrong with your engine. Most of their heat should come from the oil flowing across them.

The pivot balls create a bunch of friction, in the old days before folks figured-out how to make adequate aluminum rockers, the stiff aftermarket springs could cause the pivot balls on stock rockers to turn blue from heat. The wisdom in those days was to put a new rocker ball on an intake rocker, and move a broken-in intake rocker ball to replace the damaged exhaust rocker ball.

Since the rocker ball is the source of the most friction and heat, "roller-tip" rockers are pretty-much useless.

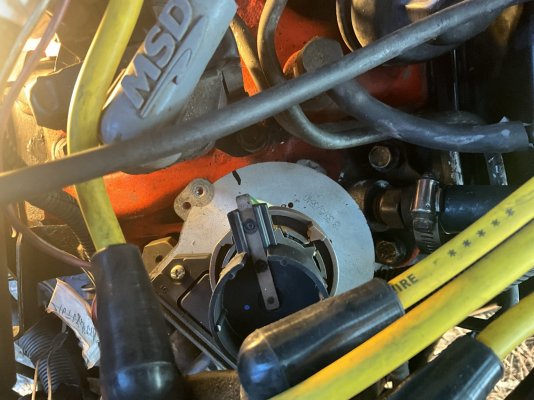

set your timing mark at what u want for start, plop the distributor making sure it catches the oil pump, Key on,

put a grounded spark plug in #1 wire

slowly turn the dist back an forth you see the spark jump ( assuming you set dist in with rotor relatively close to #1) trick is to get it to just barely have sparked, tighten down just enough to be able to move it

Works great on point-style ignitions, provide you're turning the distributor housing AGAINST normal distributor shaft rotation when looking for that spark.

Doesn't work so well on HEI or other magnetic-pulse triggered ignitions, because the slow rotation of the distributor by hand may not provide enough of a signal to the module to trigger a reliable spark.

Static-timing a magnetic-pulse distributor is more a matter of aligning the teeth on the timer core (reluctor) with the tooth or teeth of the mag pickup, no need to have the ignition turned on. Done right, and with practice, a person can "feel" the alignment based on the magnetic pull of the two parts--reluctor and pickup coil. Should get the distributor within a few degrees of the target--easily close enough to get the engine running.