Danboquist

I'm Awesome

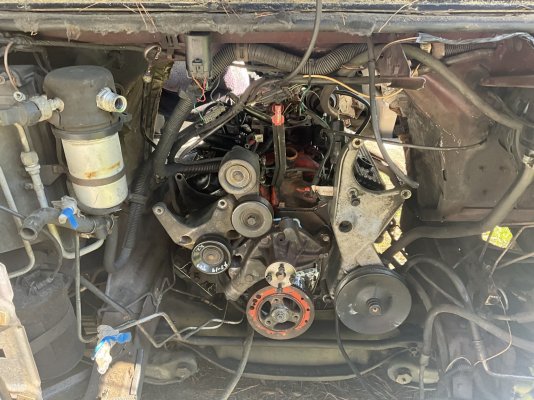

Well, the the engine is in and hooked up. This is the plan.. Any issues?

1. I’m not going to install the alternator or AC compressor yet. I dont think that I need to for the initial startup. Less junk to deal with if I have any problems.

2. I will hook up a radiator for water and transmission lines.

3. I dont know about initial timing. Most of what Ive seen people say set at 30 before TDC. That is where Ill set it to install the distributor.

4. The break in will be to run at 1500-2000 RPM until it reaches operating temperature, then turn it off and let it cool. Do this 3 times.

5. I’m thinking I can smooth out the timing/running during this without necessary trying to dial it in with a timing light. I’m thinking that once I get past this little startup/breaking thing then I can dial in the timing with a timing light. Less to deal with on the startup.

1. I’m not going to install the alternator or AC compressor yet. I dont think that I need to for the initial startup. Less junk to deal with if I have any problems.

2. I will hook up a radiator for water and transmission lines.

3. I dont know about initial timing. Most of what Ive seen people say set at 30 before TDC. That is where Ill set it to install the distributor.

4. The break in will be to run at 1500-2000 RPM until it reaches operating temperature, then turn it off and let it cool. Do this 3 times.

5. I’m thinking I can smooth out the timing/running during this without necessary trying to dial it in with a timing light. I’m thinking that once I get past this little startup/breaking thing then I can dial in the timing with a timing light. Less to deal with on the startup.