Nuggets/sludge would be bad. Since the trans has been out and TC replaced with mods to the valve body anything is possible. Just start peeling away the layers until you get there.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Noise from Bell housing

- Thread starter scott2093

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

What a mess. Should have drained transmission fluid but, I really was hoping this was going to be a simple get transmission out of the way a bit and see what was going on with the flexplate.....

Couldn't get my truck high enough and had to really tilt the transmission and there was fluid everywhere... Nice looking at least...Smelled brand new.....

Not much room at all I have to work with...

So, jacking up the truck while my son manned the jack under the engine made me think about last year when I had the mobile mechanic pull the transmission last year.... There was no supporting of the motor at any stage and the truck was lifted up pretty good in the front. Don't remember a fight with the transmission and you could sit Indian style under the truck to get a the rear main seal for example.....

I just looked through some old pictures to verify there was never any engine support.....

Should I be concerned?

Couldn't get my truck high enough and had to really tilt the transmission and there was fluid everywhere... Nice looking at least...Smelled brand new.....

Not much room at all I have to work with...

So, jacking up the truck while my son manned the jack under the engine made me think about last year when I had the mobile mechanic pull the transmission last year.... There was no supporting of the motor at any stage and the truck was lifted up pretty good in the front. Don't remember a fight with the transmission and you could sit Indian style under the truck to get a the rear main seal for example.....

I just looked through some old pictures to verify there was never any engine support.....

Should I be concerned?

I started a thread over in the transmission area for whatever ends up going on with it as it relates to this hunt for the noise. Nick seems to think the pump rotor is ok, my torque converter fluid looks very good, no weird scoring on it or anything...but...

Looking closer, and I mentioned the flexplate bolt holes earlier... I see some oddities where the torque converter pads mount to the flexplate as well. Everything was really torqued correctly so I'm not sure what could be going on but I'm suspicious.

I ordered a new GM flexplate and o-ring for torque converter...

I'll ask about the torque converter in the transmission section. Not sure I'm a fan of how uneven the mounting pads look on this one. Maybe wear was created because this was a NOS GM reman one...

Definitely want to address any issues now obviously.....

Is there any other useful information that can be had while I have stuff removed as I do? Back of the block? Any information about all those cam plugs or any advice on changing anything? Did notice the heat shield on passenger floor board is missing the foil/fiberglass material inside like the driver's side has..... Not sure if that is normal but it's right above the exhaust and , since I don't have carpet atm, it definitely is hot on the floor...lol

Here's a video of the flexplate and converter concerns I just took

Looking closer, and I mentioned the flexplate bolt holes earlier... I see some oddities where the torque converter pads mount to the flexplate as well. Everything was really torqued correctly so I'm not sure what could be going on but I'm suspicious.

I ordered a new GM flexplate and o-ring for torque converter...

I'll ask about the torque converter in the transmission section. Not sure I'm a fan of how uneven the mounting pads look on this one. Maybe wear was created because this was a NOS GM reman one...

Definitely want to address any issues now obviously.....

Is there any other useful information that can be had while I have stuff removed as I do? Back of the block? Any information about all those cam plugs or any advice on changing anything? Did notice the heat shield on passenger floor board is missing the foil/fiberglass material inside like the driver's side has..... Not sure if that is normal but it's right above the exhaust and , since I don't have carpet atm, it definitely is hot on the floor...lol

Here's a video of the flexplate and converter concerns I just took

xc_hide_links_from_guests_guests_error_hide_media

The new flexplate didn't have wallered out areas where the head of the flexplate bolts sit like mine did....

Suspicious.... but pretty much all the used ones I see online have this wear??

I wish I had bought new bolts....but didn't think it through.... They seemed fine...This time I put a little blue loctite on them....

Suspicious.... but pretty much all the used ones I see online have this wear??

I wish I had bought new bolts....but didn't think it through.... They seemed fine...This time I put a little blue loctite on them....

Attachments

Last edited:

The new flexplate didn't have wallered out areas where the head of the flexplate bolts sit like mine did....

Suspicious.... but pretty much all the used ones I see online have this wear??

I wish I had bought new bolts....but didn't think it through.... They seemed fine...This time I put a little blue loctite on them....

Hello scott2093,

I watched your video and studied your photos, and here's some thoughts:

* The (6) flexplate to crankshaft holes look like they should. The flexplate is showing witness marks

where the bolts were torqued into place, but no lateral movement, the flexplate holes are still

circular, normal.

* On the other hand, the flexplate to torque converter bolt holes look to be ovalized. Is it possible that

there was some lateral movement between the flexplate and torque converter? I would not expect

this. If enough lateral movement was occurring, then I'd expect that the shank of the bolt hitting

either side of the flexplate hole would cause an audible clicking/clanking? Was this sound the one

that you were noticing in the vicinity of the bellhousing?

EDIT: Are the same holes the same shape in the new flexplate? Or are the torque converter bolt holes

circular like the crankshaft to flexplate bolt holes shown in your photo? This will help to confirm our suspicions.

If I was your neighbor working with you I would be OK with reusing the (6) flexplate to crankshaft bolts.

But what I'm seeing at the torque converter interface would make me wonder if an improper bolt substitution

was done at any point in the past 3 decades of maintenance? To avoid a repeat, I would recommend that

new OEM-spec bolts be purchased/installed along with your new flexplate. (!) By the way, a picture of

your existing flexplate to torque converter bolts would be helpful.

****

For future reference, if you haven't already done so, consider adding post-torque tattletail marks

like @Orpedcrow did here: (No guessing if torqued fasteners have moved since flexplate installation)

Note the factory style integral shoulder bolts that better distribute the clamping load between bolt head and

flexplate surface. (As opposed to a conventional hex bolt head.)

That's all I got. I was half expecting something more dramatic given the cracked flexplate photos seen elsewhere

in this forum. But I'd consider those ovalized torque converter holes a find, and whatever you can do to avoid

that repeating may indeed solve the mystery sound from the bellhousing area.

Let us know what torque converter bolts you currently have, and anything else you discover.

Best of luck --

Last edited:

I thought maybe. Fascinating that there is so much wear. Yes, and they seemed torqued well enough when I removed them.The (6) flexplate to crankshaft holes look like they should. The flexplate is showing witness marks

where the bolts were torqued into place, but no lateral movement, the flexplate holes are still

circular, normal.

I wouldn't expect it either. I checked torque on these bolts numerous times including when removing them and they were correct. I didn't check how tight, just that they were torqued at least tight enough.On the other hand, the flexplate to torque converter bolt holes look to be ovalized. Is it possible that

there was some lateral movement between the flexplate and torque converter? I would not expect

this.

I'd like to think so. I even replaced the starter 3 times because it sounded like something tinging against something else.If enough lateral movement was occurring, then I'd expect that the shank of the bolt hitting

either side of the flexplate hole would cause an audible clicking/clanking? Was this sound the one

that you were noticing in the vicinity of the bellhousing?

Torque converter holes are oblong. attaching photo from online....but the bolt heads aren't oblong? I do think it's odd that only one of the torque converter bolts left wear similar to the flexplate bolts. The other 2 were smooth.... Not worn down....Are the same holes the same shape in the new flexplate? Or are the torque converter bolt holes

circular like the crankshaft to flexplate bolt holes shown in your photo? This will help to confirm our suspicions.

I reused them. They looked good but I had to soak them in lacquer thinner and use a wire wheel to remove the factory sealant or whatever that was on the threads. I do feel like that couldn't have been a good thing to neglect to address this last year in addition to not adding any loctite. The threads didn't even look like threads. That sealant is crazy...So these were cleaned and I put some blue loctite on them. Although sparingly.If I was your neighbor working with you I would be OK with reusing the (6) flexplate to crankshaft bolts.

What a great idea. Will definitely do this... Need to look into what's going on with lubing the crank? ..hmm..Haven't studied what that end has going on....///what ? a bushing/// a bearing???consider adding post-torque tattletail marks

They look factory... Haven't installed them yet. Little stressed about the reman converter I picked up. I've got exactly 1/8" from torque converter pads to the flexplate mounting pads when pushed back to transmission which is spec I guess...but, the next pad over seems to have more clearance..I can slip 1/8" bit all the way comfortably, probably fall out if I let go whereas one side just fits...would stay if I let go.........edit////just remembered I didn't torque the bellhousing to block yet...Just snugged up and my son snugged up the other side....maybe could be the reason.....Let us know what torque converter bolts you currently have

I'm Just over 1" from bellhousing to converter mounting pads which is good... Just don't like the way it feels when rotating it...My old one was slip and slide quiet... this has kinda a grainy feeling and I can hear that roughness.... Maybe I shouldn't be getting crazy until I get fluid properly filled.....or see what's going on on the crank end.....tomorrow.....

Just don't want to continue on my path of making things worse as I go..lol

Still want to put some miles on this last oil change so I can stress about sending in a sample....

Tomorrow should be fun too when I finally drop my transmission pan.....

Thank you for stopping in....!!

Attachments

Last edited:

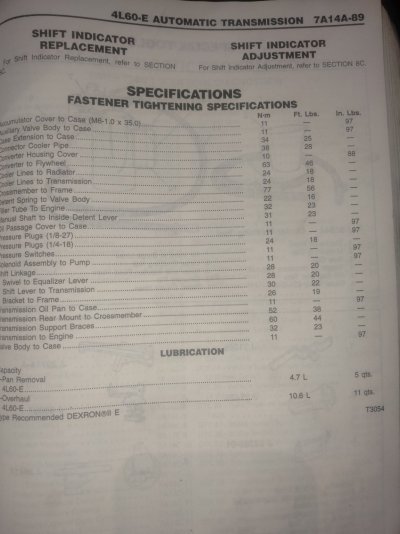

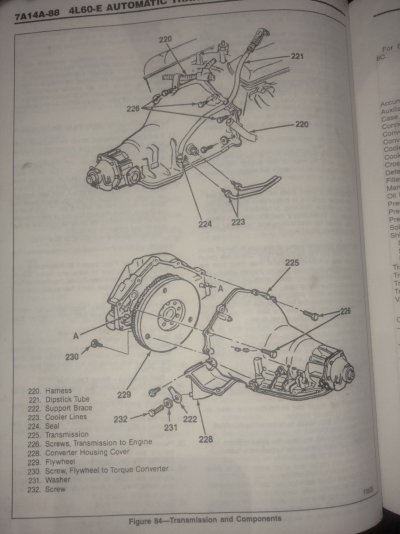

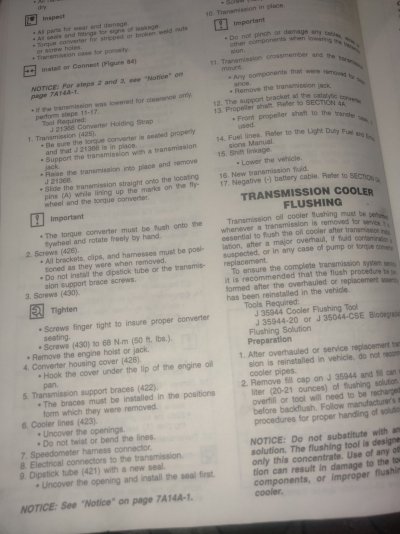

This manual drives me crazy.... for one thing, they label things in the 400s when the diagram shows the 200s....

Also There's a section that says torque converter to flywheel screws (430) which is (230) to 50ft lbs...In the specs it says 46 ft lbs....

Transmission to engine screws is only 23 ft lbs?...would have thought more.....

I guess I'll do the 50ft lbs on tc...I did 46 in the past......

frustrating.... but so is having to resize my images.... lol

Also There's a section that says torque converter to flywheel screws (430) which is (230) to 50ft lbs...In the specs it says 46 ft lbs....

Transmission to engine screws is only 23 ft lbs?...would have thought more.....

I guess I'll do the 50ft lbs on tc...I did 46 in the past......

frustrating.... but so is having to resize my images.... lol

Attachments

* On the other hand, the flexplate to torque converter bolt holes look to be ovalized. Is it possible that

there was some lateral movement between the flexplate and torque converter? I would not expect

this. If enough lateral movement was occurring, then I'd expect that the shank of the bolt hitting

either side of the flexplate hole would cause an audible clicking/clanking? Was this sound the one

that you were noticing in the vicinity of the bellhousing?

EDIT: Are the same holes the same shape in the new flexplate? Or are the torque converter bolt holes

circular like the crankshaft to flexplate bolt holes shown in your photo? This will help to confirm our suspicions.

The original flexplate suffering from "ovalized torque converter bolt holes allowing noise to be generated"

theory may be wrong. After sleeping on this I took a fresh look at the video screen snap that made

me wonder:

You must be registered for see images attach

I was expecting a perfect circle here, like what we see at the flexplate to crank bolt holes?

To prove/disprove the 'enlongated hole from wear' theory, I then took a close look at the

brand new GM flexplate. From here it looks like (4) of the 6 torque converter bolt holes

are manufactured horizontally oval shaped, while the remaining (2) holes are vertically oval

shaped?

You must be registered for see images attach

I'm assuming that these torque converter bolt holes are made this way in order to allow

for necessary manufacturing tolerances between the torque converter and the flexplate?

Obviously if I'm wrong then I'm hoping that a Subject Matter Expert will step in and

clarify all this?

So after giving the new flexplate close scrutiny, I'm thinking that the new flexplate

isn't going to make a dramatic difference in the quantity of noise in the vicinity?

At this point I have to step aside and let the flexplate/torque converter/transmission

gurus take the helm.

This is a tough one...

Last edited:

Well you did ask to verify . More like the hypothesizing didn't pan out..lolThe original flexplate suffering from "ovalized torque converter bolt holes allowing noise to be generated"

theory may be wrong

But still odd to me is , like the screenshot you just posted of my video, that is the only one of the 3 bolt surfaces that has wear that affected the depth of the metal. The other 2 are flat. Just witness marking more or less.... no wear,,,, I'll get a pic in a bit....

It may be the TC is starting to come apart. Trans filter and pan should be informative.

Went ahead and took the pan before proceeding with installing transfer case..etc...Nuggets/sludge would be bad. Since the trans has been out and TC replaced with mods to the valve body anything is possible. Just start peeling away the layers until you get there.

No nuggets but there is sludge? Not sure if normal or not......looked pretty clean.... been just over a year since I had changed filter and fluid in pan...and whatever was changed when the reman converter was put in last year as well.....

xc_hide_links_from_guests_guests_error_hide_media

Added pics of the 3 mounting areas bolt sideBut still odd to me is , like the screenshot you just posted of my video, that is the only one of the 3 bolt surfaces that has wear that affected the depth of the metal. The other 2 are flat. Just witness marking more or less.... no wear,,,, I'll get a pic in a bit....

Also, the new reman converter I put in last night was making a disturbing rough sound when spinning. A little bit ago while I was trying to fish some grease up to the crank bushing? where the converter rides, I noticed the scratchy rough feeling was evident when pulling the converter to and from the flexplate as well....

Went through my pictures I took when converter arrived and see rust.... Could this be what I'm hearing and what are the implications of it being there? Will fluid get going once everything is moving? I can't believe it slipped my mind to inspect again before installing it.... I get a bit over excited when my son is available and willing to help so I was rushing a bit during the transmission install......added pic of the rust I'm describing

Attachments

Similar threads

- Replies

- 9

- Views

- 1K

- Replies

- 1

- Views

- 175