Great stuff L31ME!

I had a little time yesterday and today to work on the AC. I had my neighbor with the machine pull the refrigerant yesterday. He recovered roughly 64 oz which is spec for this suburban, so that was good. I still replaced the high pressure valve.

1) I slapped on the four seasons compressor 88947 with the smaller pulley. Luckily happened to have a slightly shorter belt that fit perfect. The compressor case looks same size as the Delphi I pulled. But it is larger 210cc capacity?

2) I swapped in the Boxi parallel flow condenser (Part number in my last post) It was a good stock fit.

3) I swapped in a fixed 0.062 orifice tube.

The one it replaced was preinstalled in the new UAC refrigerant y-line I installed with winter overhaul. It appeared to be slightly smaller orifice than the 0.062" fixed that is now installed.

Pulled a vacuum for over an hour to draw out any moisture. Held vacuum perfectly for over an hour. Looking to recharge tomorrow. Just need to decide on putting r134 back in or giving the r152 a shot. I will probably just have r134 put in for now just to limit the variables. I should have case of r152a, side canister tap arriving in next day or two. So if the system is still not up to *****, I will consider trying r152a.

I haven't installed the pusher fan. Looks like I will have to relocate the trans cooler or the engine oil cooler to make the aux fan fit. That will have to wait until winter.

I do have that adjustable low side cutout switch on hand (and connector), and have not installed that yet. What's a good way to determine what pressure current stock switch is cutting out at? Same question for high side cutoff switch? Is there a test with gauges or ??

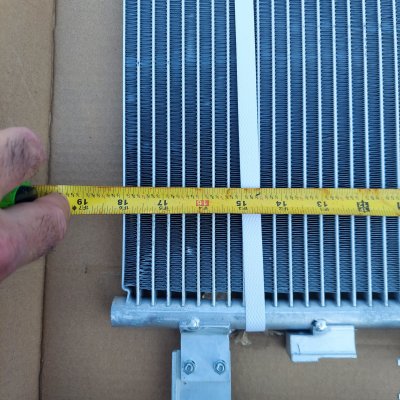

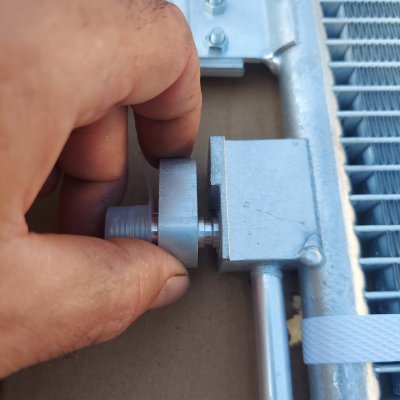

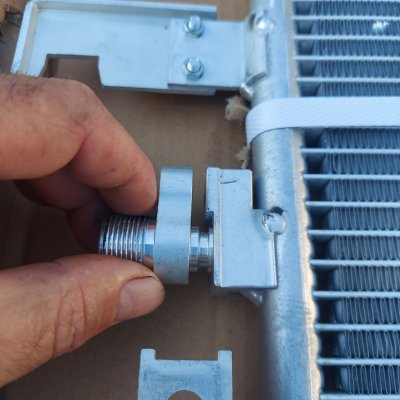

Lastly, the Agility 7010190 condensor arrived today. It is the late model Tahoe one L31ME recommended. It is a little big. At 18" tall some modification of the rad support would have to be done. The generic line fitting adapters did not fit so I settled on the stock size Boxi condenser. The Agility 7010190 looks like it would definitely perform well with its large size and subcooler, but it looks to require 1) rad support modification, 2) possible hard to find adapter fittings 3) custom lines to and from condenser as the width puts the fittings past stock location up tight to the passage hole on the rad support. It could be done, but if there was a similar condenser out there 10% smaller in width and height.