Road Trip,

According to 1998_K1500_Sub in the previous thread:

"Here's what the 1998 FSM says about P0157; see the attached .pdf.

It says the system goes open loop when the code is set.

It also talks about checking the LT trims... "If the conditions for DTC P0157 exist, the L.T. fuel trim values will be around 158 or greater.""

I thought that open loop means that it does affect performance?

Excellent question. And I stand corrected, for forcing the engine out of the most accurate mode

(Closed Loop) back to the factory settings with zero local fine tuning (Open Loop) *can* lead to the

same

or worse efficiency & emissions. But I'd like to explain why I wrote what I did in reply #4 above.

When it comes to these computer-controlled engines, there are specific modes of operation. And depending

upon what goes right vs what goes wrong, we can have engines that run well during warm up, and then suddenly

run much worse once they are fully warmed up. Conversely, we can have engines run rough & misbehave

when cold, but suddenly start driving fine when warmed up. And of course, run poorly hot & cold. And the

highly desirable runs well hot or cold.

Here are a few rules of thumb that can help with troubleshooting drivability issues:

* With a stock/unmodified engine in factory-fresh mechanical condition, with the matching

computer it will run from very well to *excellent* on the stock fueling & timing tables in the computer even

without any local feedback. (aka: Open Loop)

Q: If this is the case, then why all the hoopla over Closed Loop operation?

A: As the miles accumulate on the odometer, the physical state of the engine + the injectors +

all the sensors all start to drift further and further away from that initial factory-fresh condition.

Which also means that the efficiency & performance will drop while at the same time emissions

will climb. But by adding the O2 sensors to the exhaust and using them to incorporate a feedback

loop, this gives the engineers the ability to constantly measure how close to the ideal we got, and then

use this info to compensate for this drift & fine tune the A/F ratios in real time. (ie: successfully drive

the O2 sensor(s) back and forth across the stoich voltage value >8 times per second.

)**

That's the theory that they were following when they designed/build your engine. And when it

works, it works great. But when it doesn't work, as a troubleshooter we are trying to figure out

what we are dealing with:

I) (Ideal) Engine runs as designed. Cold start in Open Loop w/good driveability & minimal emissions.

When engine coolant and O2 sensors cross the temp thresholds, system goes into Closed Loop,

imperceptibly to the driver, and engine delivers excellent drivaility, best mileage, and lowest emissions.

NOTE: When driven at/near WOT, a healthy engine/computer combo stops chasing Stoichiometric

A/F ratios, intentionally falls out of Closed Loop operation, and runs off of the factory table values

for the duration of the heavy throttle/high power demands by the human. And once the driver

eases off the gas, the engine will revert to Closed Loop (stoich) operation.

II) Engine/sensor parts have drifted, adversely affecting Cold engine operation. However, once the engine

warms up and goes Closed Loop, engine begins driving normally. If engine is forced to go Open Loop,

poor drivability returns. DTC will be kicked once the resulting emissions levels are calculated to exceed

150% of the calibration. (Diagnosis: Worn engine components being compensated for by a healthy

Closed Loop system.)

III) Engine runs good during cold operation. (Open Loop) However, once the engine warms up and

goes Closed Loop, misfiring, rough operation and/or poor driveability commences. If the engine

is forced into Open Loop operation, the engine starts running well again. (Diagnosis: Good engine

adversely affected by worn out Closed Loop components. {O2 sensors, cats} )

IV) Engine runs poorly cold or hot. Going Closed Loop may even exacerbate the condition. (Diagnosis:

There is a mechanical issue with the engine, fuel delivery, or ignition system preventing proper engine

operation...no different than in the old pre-computer days. The computer can't compensate for

burned exhaust valves, a camshaft missing one or more lobes, stuck injector, or bad rotor, cap, or

spark plug wire. (Hopefully

identify the misfiring cylinder(s), but not compensate for the problem.)

****

I apologize for the length of the above, but in my humble opinion the fact that our computer-controlled

engine bays have these 4 different modes of behavior is the reason why so many problems in the middle

of the range that can be tuned around will present as if they are 'intermittent'. And also why so many

parts can be thrown at the engine bay and yet the desired fix remains elusive.

I believe that when this new feedback loop mode was being introduced to the truck world with the GMT400, the

technical support organization was worried enough about the local feedback loop clouding up the troubleshooting

that they went to the trouble of adding the "Field Service" mode into the TBI computer, so that a Regional Level

Troubleshooter could monitor Closed Loop operation via the SES light while troubleshooting a customer's

'can't be fixed' driveability complaint. (!)

So with all of the above setting the context, my comment about the upstream O2 sensors having the power to

negatively distort the Closed Loop operation (Scenario III) is always top of mind. And that for the GMT400 family,

the downstream O2 sensors do

not have that same influence on the Closed Loop operation. This is still true.

But when you pointed out that the rear (downstream) O2 sensor(s) can fail that DTC and this throws the

computer into Open Loop operation is also a direct effect, by eliminating Closed Loop operation entirely. (!)

So let's use some of the theory above to troubleshoot that DTC P0157.

* Let's say that some crusty wiring is not accurately coupling the B2S2 oxygen sensor

output back to the computer. The voltage is too low as a result. The test fails, a DTC P0157 is kicked, but the

engine continues to run well, the spark plugs are coloring correctly, so the SES light is on but the engine bay is happy.

(Diagnosis: Good engine, with a problem solely with the feedback loop.)

* You fix the O2 wiring back to new condition. Now *both* downstream O2 sensors are in agreement. SES light remains out,

life is good. Or possibly SES light comes on, and *both* O2 sensors are complaining. This is when you should focus

on finding the root cause that is causing a global failure across both banks. (Diagnosis: Out of tolerance component

in fuel delivery subsystem affecting both engine banks.)

Note: When your engine was running lean due to the empty primary tank (fuel gauge non-zero due to secondary tank malfunction)

resulting in a truly too-lean condition, in the perfect world *both* left and right downstream sensors should have been

complaining. Actually, I would have expected the upstream sensors to have kicked DTCs also?)

It feels more sluggish when the code is live, but that is subjective. I don't have good instincts on this truck yet, haven't driven it long enough. Also have a tendency to be bothered by check engine lights so it may be causing me to feel like the truck has less power.

This could very well be. For example, the factory tables were calibrated for the fuel being sold at the time,

which was 100% gasoline, 0% ethanol. With 10% ethanol adopted years later, there will be a minor adjustment

in the LTFTs (Long Term Fuel Trims) ...which helps to explain why you rarely if ever see a perfect +/- 0% trim value.

And of course if there is any component in your engine bay that has drifted from the value when it was

originally manufactured/passed QA checks, then when not compensated for during Open Loop operation, can

lead to a difference in engine behavior that a detail-oriented driver may be able to discern.

****

To recap, an engine/computer combo can be in any of the following Modes of Operation:

* Healthy engine Open Loop + real time optimization via local, healthy Closed Loop system.

* Healthy engine Open Loop

misadjusted by broken Closed Loop system.

* Engine with drifted/worn parts causing bad Open Loop misbehavior, but successfully compensated for by Closed Loop. (Successfully anticipated by design engineers.)

* Engine too far gone, bad Open Loop *and* bad/worse Closed Loop behavior.

This is a lot of theory just for crusty wires or tired O2 sensors, but I was trying to figure out why

you didn't get too lean O2 DTCs for both banks? Which made me wonder if a marginal wiring path

was the real cause of the 'too low voltage' on the B2S2 sensor?

Enough for now. Let us know what you discover. But you aren't going to hurt your engine by

running it Open Loop until you can get a chance to take a closer look at all this stuff.

Hope this explanation was helpful.

Best of luck --

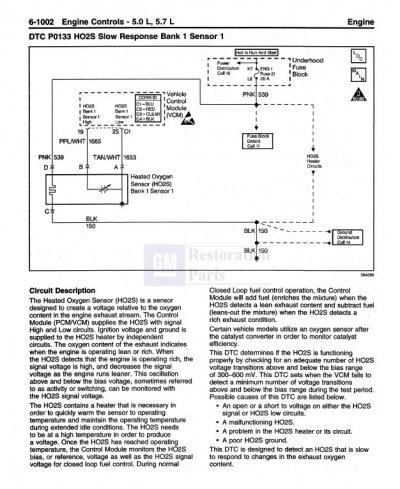

**There's been some question about how fast healthy O2 sensors can be driven by the computer

to cross/recross the 450 millivolt (stoich) voltage. Drive leaner (cross) now drive richer (cross)

and repeat. According to the FSM, if it takes more than 125 milliseconds on average (8 Hz, 8 times per second)

then supposedly a P0133 "Slow Response" (Bank 1 Sensor 1) and/or P0153 "Slow Response" (Bank 2 Sensor 1)

DTCs will be kicked. (See attached.)