I was told it would do the trick. Seems to be silicone.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'98 5.7L P0157 sensor or actually lean?

- Thread starter big bird

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Thank you for the very thorough answer. It is greatly appreciated. I understand most all of it.

Glad that made sense. These computer controlled engines can be a bit of a steep learning curve,

especially if the aging feedback loop components are distorting the troubleshooter's perspective.

I think it's safe to assume that components have drifted and I would be better off running closed loop if it isn't too much trouble to find/fix the problem. Main priority remains fixing the gas fill issue.

Agree on both counts.

My next step will be cleaning connectors, putting exhaust tape around that dodgy looking cat gasket, and maybe figuring out what that loose connector is.

If you can clean off the wires going to that loose connector and either list the colors and/or post a picture,

a lot of times we can match that up to what's listed in the wiring diagrams. Actually, a few folks in here seem to be able to

look at a photo and tell you exactly what that connector is for off the top of their heads. Lots of talent & experience in the

audience.

As to the question of that sensor being able to quickly cross, the CEL is coming on during heavy acceleration, 4000 RPM uphill in fourth. I would think that would get some quick variations in lean/rich. The code is present before the light comes on, we had the OBD2 reader plugged in after we got going to monitor it. This is pushing the engine real hard, but if she'll do it, makes my life easier on a 700 mile interstate trip.

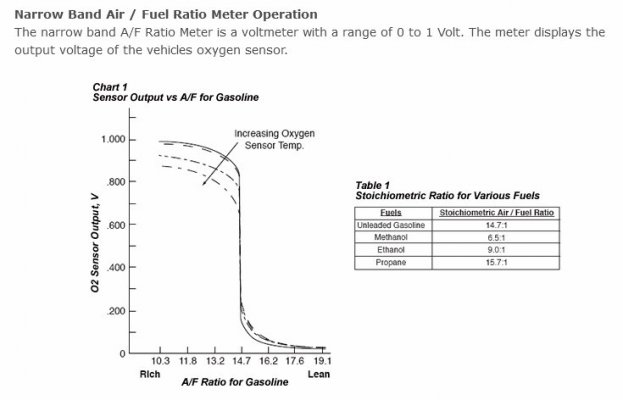

OK, here's where the theory above comes into play. Remember, if you are working the engine hard enough it's going

to quit chasing stoich and run Open Loop. (NOTE: 14.7:1 is stoich, best long-term power is ~13:1 A/F for a lot of reasons

left for another conversation.) So, since our generation trucks are using the original 'narrowband' O2 sensors (which act in

a binary voltage way in response to too lean/too rich mixtures, see attached) ...this is why our trucks have to go Open Loop

for heavy load/heavy throttle conditions. This behavior is an artifact of the techology employed in the feedback loop -- a feature,

not a fault. But we need to keep track of this in order to better answer the following question:

Think I should change out the sensors or leave them alone?

Given all of the above, from your description I'm thinking that your truck is running Open Loop

during the heavy throttle in order to achieve the correct full power A/F ratios. Which means

that the suspect O2 sensor is not involved at that time?

But like you said, if we can get the truck to run Closed Loop whenever it's supposed to *is* preferable

to just running around Open Loop all the time. So in theory the R&R of the sensor sounds like a good plan,

but at the same time I'd caution you that the old O2 sensors can really put up a fight when you are trying

to remove them.

Especially given that you are still moving, I'd try to remove it, but if it doesn't want to come apart with normal

effort I'd defer maintenance on this until the dust settles. Again, running Open Loop isn't going to age/stress/damage

your truck at all. (assuming a VCM working like new, healthy engine, etc.)

****

As you mentioned earlier, getting the primary gas tank to be able to take the fuel during a normal fill up is your main

priority. And when you get around to replacing that O2 sensor kicking a code, don't be surprised if this doesn't clear

the code, for it may be a marginal wiring issue between the suspect sensor and the VCM. In a perfect world you'd have

access to a scan tool that can graph live data and we could see what the computer is seeing, eliminating all the

inferencing/best informed guess repair strategy.

Hope this further clarifies what I'm trying to describe. Just don't want to tell you

to throw parts at something which may fix 'a' problem, but not 'the' problem.

Keep us informed as to your progress. Safe travels --

Attachments

I was able to change the passenger side downstream sensor. (The one reported in the code). Also added that tape.

Wasn't able to get the driver side sensor out, it's even a different manufacturer. Decided not to worry about it for now, one of my O2 sockets sprung, the other started rounding it off. Torches and big wrenches can wait till after the move.

Code didn't come back with hours of hard driving.

I'm considering it fixed, doubt the tape did anything, think the sensor was bad/marginal.

Wasn't able to get the driver side sensor out, it's even a different manufacturer. Decided not to worry about it for now, one of my O2 sockets sprung, the other started rounding it off. Torches and big wrenches can wait till after the move.

Code didn't come back with hours of hard driving.

I'm considering it fixed, doubt the tape did anything, think the sensor was bad/marginal.

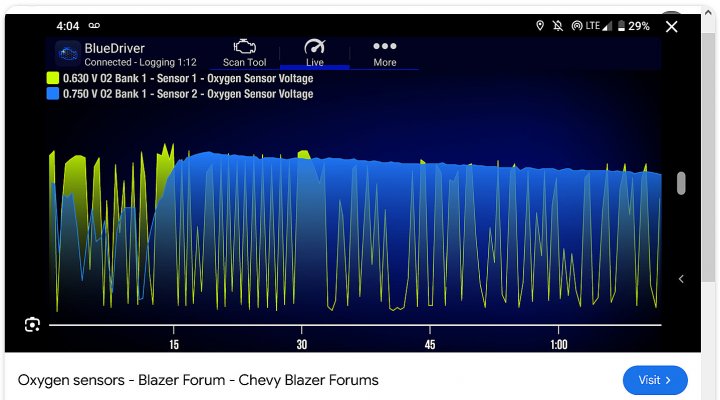

That is a consideration when dealing with data feedback from O2 sensors. With scanner and live display you can see the voltage quickly , 3,4,5 times a second changing up and down.

But as age and slow contamination builds they get slow and lazy, therefore the ecm sees that as a malfunctioning engine condition. Verify O2 info then proceed. That is the reason for checking the O2 sensor, is it functioning normally or is it losing its mind.

But as age and slow contamination builds they get slow and lazy, therefore the ecm sees that as a malfunctioning engine condition. Verify O2 info then proceed. That is the reason for checking the O2 sensor, is it functioning normally or is it losing its mind.

Similar threads

- Replies

- 0

- Views

- 175

- Replies

- 18

- Views

- 2K

- Replies

- 58

- Views

- 2K

- Replies

- 8

- Views

- 1K

Members online

- EyeSac

- Alteca

- Plumbintime

- lambchop4416

- SNCTMPL

- sactown

- fancyTBI

- Check251

- jinks67

- Spyder5007

- Bena

- SierraK2500

- Vikingdude

- BobL

- tom68154

- 95flatblack

- Caman96

- gmstd66

- thesuntail

- 1995K2500LD

- jwlehman

- cowman66720

- 95burban

- El Tigre

- Dutch1134

- shablagoo_gabagool

- dotwell69

- Brando_o

- lght1

- jeepguy

- 0xDEADBEEF

- Crashdawg2099

- Laredo1307

- rscrawford

- 98redrocket

- majack82

- Jmay25

- Squares R In

- jay g

- Frankinstyn11

- jdjonesdr

- dw0278

- dzynda

- evilunclegrimace

- tahoe.mkIII

- Olbugger

- yrusohi

- rray670

- Ben_In_TN

- Leeztruk

Total: 1,670 (members: 114, guests: 1,556)