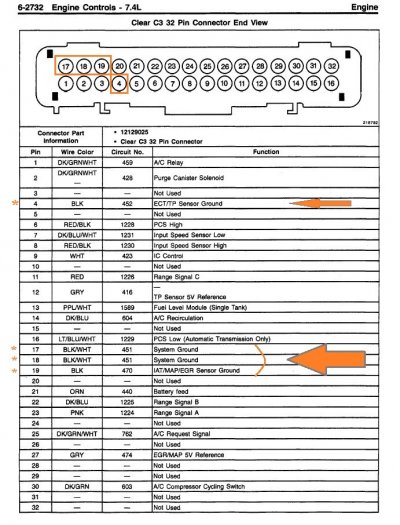

I don't know about you, but I'm thinking the VCM sensor ground circuit needs to be checked in detail:

From your comments I can tell that we are thinking along the same lines, troubleshooting-wise. No doubt

that normal parts replacement can't fix what ails this particular vehicle. And the OP mentioned that he had

a couple of mechanics look at this, as well as the fact that you can tell from his troubleshooting notes that

he has dug into this more than most would have. When someone is trying this hard to solve a tough problem

it really makes me want to help in any way possible. (!)

This reminds me of a crank-no-start problem I debugged on a Dodge pickup.

In that case, the VCM's power ground (which is the VCM's ground connection to the chassis) was open-circuit. The VCM was half-alive tho, as it was using its sensor ground circuit as its power ground... which worked well enough for it to appear sane, but which was insufficient when the VCM tried to fire the injectors.

Take-away / To-do: Check the VCM power ground to the chassis. Do this by disconnecting all connectors to the VCM and then measuring the resistance between the relevant pins in the VCM harness and ground at the engine block.

This should measure ~0.2Ω.

Finally, check the VCM's internal connection it provides between chassis ground and sensor ground. With the VCM's four(?) connectors disconnected, measure across the relevant pins of the VCM (sensor ground, chassis ground) and confirm ~0.2Ω.

@2jduenas, in order to get an even better idea of how a marginal ground can allow partial operation of a computer-controlled

system, take a moment and read what 1998_K1500_Sub wrote: (Engine starts but dies after engine swap)

Just to set expectations, a straightforward 'bad sensor on a good wire' failure may take an evening or two to troubleshoot. A single completely

open or shorted wire that is known to fail (due to a known stress/design issue) can take a week or so (evenings after the day job) to track down if

the failure is hidden under the dash or behind the engine. Especially if your mentor is remote instead of working shoulder-to-shoulder

under the hood.

But when it comes to a 'marginal' ground, this can take a lot of time. Especially when there's a flurry of associated symptoms,

DTCs, etc. These kinds of failures force us to get the books out, develop theories, and then test the theories and learn from

the results.

And since the OP has tried multiple fuel level sensors and even tried swapping out the VCM, I think that everything here points

to testing/repairing/verifying the signal paths as Nitro Junkie is recommending.

****

As for test equipment, I believe in a measured response:

1) If the computer can detect an anomaly (SES light + DTC code) then I try to clear that first.

2) If the factory troubleshooting process for that DTC can be performed using a DVM, then proceed with that.

3) On the other hand, as soon as the factory troubleshooting process recommends using a Scan Tool that will show real time data, then of course we must step up our game.

4) And if there is no SES light and yet the vehicle still isn't running right, then of course you need to monitor live data in order to see what the computer is reacting to/being fed by it's sensors.

5) And if the (VCM A/D processed) live data still can't shed enough light on the problem, then ultimately looking at the raw signals with a scope may be required.

NOTE: This is a comprehensive troubleshooting approach when a completely stock engine bay is being worked on. Obviously once a non-stock tune, 0411 upgrade,

or nonstock engine parts are employed, then all bets are off, and the sky's the limit. :0)

For what it's worth, this is the approach we used on our aging F-16s when we had a stubborn malfunction like this where no amount of

black box swapping was going to right the wrong. And although we used terms like like 'MFLs' and 'T.O. Library', the actual process was much

the same -- sometimes we would reach the end of the troubleshooting fault trees and still no joy.

And this was when we would stop, develop one or more theories, and then employ a 2nd 'known good' jet for comparison purposes.

(Didn't happen often, but I still remember these episodes clearly.)

Given the above, if we get to a spot where a 'known good' GMT400 might help us figure out stuff that's beyond what is in the FSMs,

I'll be happy to try and duplicate those engine bay measurements on my '99 454 C2500. (Obviously a known-good '98 engine bay would

be even better, but something is better than nothing.)

More in a bit. Going to compare '98 vs '99 VCM <> engine grounding -- I think that a change was implemented between the years, but

want to confirm this before continuing.

Last edited: