### Next Steps:

1. **Inspect Looms:**

- Check for any damaged wires, poor splices, or connections.

- Repair any issues found and re-test the system.

2. **Run New Grounds (if needed):**

- If the issue persists, run new signal grounds to ensure each sensor connected to pin 19 has a reliable ground.

By following these steps, I should be able to address the P0101 code and ensure the reliable operation of the truck’s sensors and fuel level gauge.

Your thoughts?

Hello 2jduenas,

Your detailed writeup is appreciated. Over the years I've fixed my way out of electrical warning harness issues

in a couple of different ways. It depends upon the situation, so I'll try to clarify below.

1) From hard-won experience I've learned that a wiring harness and a head of lettuce have a lot in common.

That is, the edges go bad first, but the center can stay good for much longer. Given this, I have no problem

repairing the existing wiring harness on the tattered edges as needed, as opposed to completely swapping out

the entire wiring harness just in order to fix one or more tough intermittents. IMHO, the 'new' harness is very

labor intensive, both in the treasure yard as well as the problem vehicle, and it's also too easy to introduce

new errors during installation. :-(

2) If I'm on the side of the road/long way from home and I've troubleshot to a bad wire, I won't

hesitate to substitute a new length of wire for the bad one in order to get me home.

Also, if the vehicle is in it's last salt season and will be cheerfully retired the following spring, then I'll run a

new wire as a temporary fix with no regrets. (Mindset = I'm not looking for more trouble, I just want

to fix what's known bad and get back asap to the crisis du jour. :0)

3) If I'm troubleshooting in my shop and I discover a bad spot in the harness and/or a burnt connector,

I'll take the time to inspect/test/repair the existing harness. (Mindset = I am going to repair what's bad,

and while I'm in there I am going to take the initial failure as a warning that I need to proactively look for

more trouble in the harness, and not hesitate to fix anything I find.) Especially if I'm working on a 'keeper'

or 'forever' vehicle. I've never regretted a careful fix that it still working years later. :0)

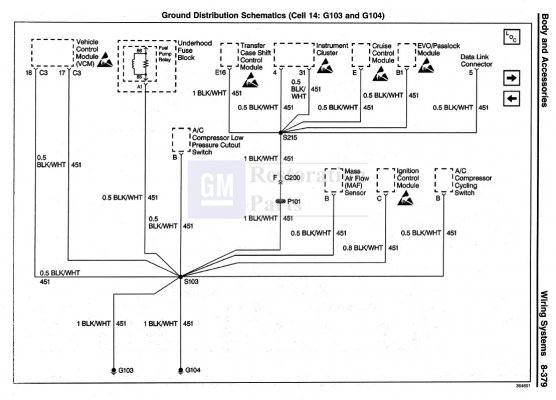

And your comment about ensuring good grounding between pin 19 C3 and all associated sensors is a solid approach.

The bottom line, the more solid your ground and power distribution system, the way more rational that

all your sensors will be acting (from the VCM's perspective) ...making your electrical troubleshooting life

down the road with this vehicle that much more straightforward. Making your power

and grounds robust

is time invested instead of just time spent. (!)

And you have just proven this by what you've accomplished in your reply #60.

****

Re: The remaining P0101 DTC. I'd like to dig into that a little more before commenting.

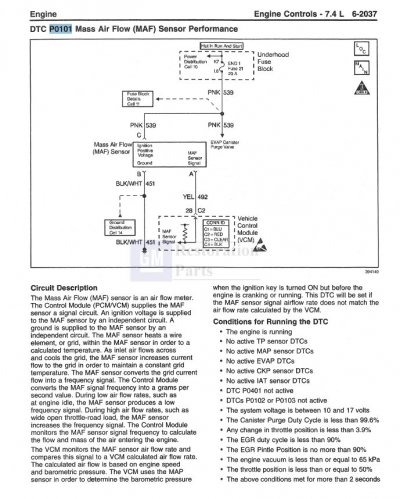

P0101 = Mass Air Flow (MAF) sensor performance. Many a parts blunderbuss has been

loaded with a new MAF right after the computer throws a P0101, with no improvement

afterwards. (!)

In order to try & reason our way through a P0101 popping up after so many other DTCs

have been cleared, we need to read the (5) pages in the FSM for this code before changing

any parts. The first thing we need to do is to understand *why* the VCM decided to kick

this code. (!)

Quoting the FSM: Conditions for setting the DTC -- "The actual MAF value is not equal to

the

calculated value for more than 5 seconds."

Now, according to the FSM, the VCM uses the inputs from the TPS and the MAP in order

to come up with the calculated value. The book explicitly warns that a bad TPS sensor

can cause a miscalculation. Also, if the MAP sensor output is out of tolerance ("skewed")

then the VCM could be basing it's MAF calculation on an inaccurate BARO reading, again

creating an erroneous calculated MAF value to compare the real one against. (In other

words, a false indictment.)

So at this point, we need to keep in the back of our mind that the VCM is reliant upon good

MAP & TPS readings (plus +12v MAF, +5v Ref TPS & MAP, sensor signals, and sensor ground

wiring) in order to come up with something to correctly compare/judge the actual MAF sensor's

functionality. (!)

****

So the above describes the why. But why now? Did fixing the original wiring issue somehow

cause the P0101?

Under the "Conditions for Running the DTC", there's a long list of conditions that must be met

before the P0101 DTC is allowed to run. Here's a shorter list that's related to our situation:

*

DTCs P0102 and P0103

not active (MAF low, MAF high)

* No active MAP DTCs

* No active EVAP DTCs

In other words, the P0101 MAF Performance test was inhibited from running while related DTC

failures were already occurring. So on a vehicle suffering from a long-term multi-DTC failure,

once the original problem is fixed, it's quite possible for a (previously latent) failure to bubble

up and again set the SES light & kick a fresh code.

****

Once our previous methods fail to make further progress on these newer failures, now what?

OK. This is key. Before going any futher, ensuring that the MAF enjoys the same robust

power and sensor ground connections as the other sensors is a given. In addition, there's

a specific mention for this DTC having to do with interference from other systems:

"A misrouted harness. Inspect the routing of the MAF harness to ensure that it doesn't come

too close to high voltage wires such as spark plug leads."

And who knows? You might find an additional wiring fault where fixing the same will clear the

P0101 DTC. If so, great!

But IF not, then a careful reading of the P0101 section of the FSM tells us that input data

from the sensors specified in the troubleshooting flows is key to figuring this out. And they

reference the use of a Scan Tool in order to look at the values of the signals related to the

kicking of the DTC P0101.

****

So here we are now at a troubleshooting threshold. By focusing on the commonality of all the

DTCs being kicked, that eventually lead you to finding/fixing a wiring fault. By doing so,

now the DTC 0101 was allowed to run, and it now flagged as an error.

The troubleshooting question you need to answer is:

* Is the MAF actually bad and is the

perpetrator of the failure?

* Is the MAF actually good and is the

victim of the VCM misidentifying

the MAF as bad. If so, is the VCM being misled by a skewed input from

either sensor it's using for it's calculations/comparison? Or are the other

sensors good and the wiring to the VCM is sketchy? Or (worst-case scenario)

the VCM has an internal component failure and is incapable of getting it right?

Q: How to we figure this out prior to replacing parts?

A: Carefully studying the live data via employing a scan tool capable of sharing

the necessary data.

NOTE: Others have used the parts cannon. Actually, this will work IF you get a

(good) new part and the original MAF was the perpetrator of the failure. On the

other hand, all the times you read about a $$$ MAF swap and no improvement?

That's the case where the MAF was the

victim of being misidentified as the problem,

so obviously replacing a good part with another good part isn't going to give us any

repair traction? FWIW, here's a thread about a MAF being swapped out but no joy.

Unfortunately this thread dead-ended prematurely: (

MAF swap, but no joy)

To summarize all this, MAF sensors do go bad. If after the wiring guru {you} verifies

that your MAF enjoys the same good power, ground, and signal connectivity that the

Fuel Level Sensor now enjoys, it's time to up our troubleshooting game and take it to

the live data level.

Note: If you have access to a free, 100% known-good/flown-good MAF, then you can swap this

in and get a quick go/no-go answer. Please note that I did not say a "new MAF", for today's

troubleshooter knows that new parts are just another unknown which must be proven good/bad

before relying upon it. (!)

Assuming that a known-good MAF isn't available, then let's look at what the existing MAF, TPS,

and MAP sensors are putting out. With live data, we actually get to look over the VCM's shoulder

and see what it's interpretation of reality is.

And if you haven't already picked your own OBD-2 scan tool out, then say so, and others can

chime in with what's worked out best for them.

And if you post those readings here, then I will commit to getting the same data from my 'known good'

'99 454 C2500. This way if you are getting similar readings as I, then we can back-burner those areas

and focus elsewhere. But if we get a mismatch, then we'll investigate that until we can explain why...with

the ultimate goal of changing only the part(s) that are directly contributing to the P0101 DTC.

****

For what it's worth, I'm looking forward to you getting this truck to run with -0- DTCs. You have made

significant progress since the 16th -- I can almost smell the finish line from here. :0)

PS: Revelant FSM pages:

'98 FSM P0101 section: p. 6-2759<>6-2762 ;your year truck

'99 FSM P0101 section: p. 6-2037<>6-2041 ;similar to '98 writeup, with improved Circuit Description (See first 2 pages in attached.)