What are your goals with this engine? If this was a carbureted car and it really needed to be pressed into service

in a cab company that had way too many broken vehicles in the fleet, then getting the 1 cylinder close & the other up

to only 20% leakage?

Why not? We need something that will move under it's own power in order to pay the bills. Hammer it a few more times & Send it!

(No sarcasm. This kind of thing happens in the real world all the time.)

****

On the other hand, if this is going to be an engine under tight computer control, and is something that you

expect to be able to hop in, start it, and it runs without intermittently kicking codes, hesitation when taking off

from a light, worse than average gas mileage, and bringing driveability issues to this forum, only to have to

listen to us talk about misfires creating a 'false-lean' reporting by the O2 sensors misleading the computer,

etc...then getting a brand new engine to 'only' have 20% leakage in 1 cylinder? Given this scenario, I don't

think it's wise to push ahead with known issues with your valves/valve seats.

In English, back in the much looser tolerance days of carburation, mechanical centrifugal advance, and vacuum

advance canisters, any mechanic worth his salt could tune an engine around stuff like sticky valves and iffy

valve seating. Most engines started getting tired after 75,000 miles of use, and very few were ever in a

sharp state of tune. Richen up the jetting just a little, twist in a couple of degrees of advance, and if the

engine pinged on the highway, then run some 29¢/gallon Ethyl in it. But at the same time these engines

put out a lot more HC, CO, and NOx than today's engines do.

****

Let's stop and think about what your shop foreman did. By tapping on the tops of the valves he was

able to improve the valve seating? Now he didn't straighten any bent valve heads by doing this, so the

only other answer I can come up with is that the valve stem to valve stem guide clearance is *too tight*.

Tight enough that those valve springs couldn't overcome the friction between valve stem and guide, so

the valve stopped moving before being fully seated against the seat. Now keep in mind that you are

experiencing this at room temperature. When the engine fires and everything comes up to operating

temperature, hot valves get rid of heat in 2 places: the valve head at the valve seat, and the the valve

stem through the valve guide.

If there's a clearance issue at room temperature, given that metal expands when heated, it is only going to

get worse as the engine runs. If that exhaust valve hangs open, it will NOT cool properly, and there's a

good chance that it will burn up in short order. (See 1st attached for an exhaust valve I burned because

I neglected to perform the recommended valve lash adjustment at the scheduled maintenance interval.)

And I've worked on high mileage, tired motors with 20% leakage, and I could get them to run 'good enough',

but with anything I care about I want all the cylinders to read very close to each other, with a goal of maybe

5% leakage tops.

But it really doesn't matter what I do with my motors. What's more relevant is what are YOUR plans for

this powerplant?

* Flip it as-as, as shown, no guarantee that it will run without a SES light or passing emissions testing?

Then you get to use a hammer to help the valves to the home position & ship it.

* Put it together and get it to run smoothly on the computer, pass the emissions testing with ease, and

'get to drive it' instead of 'gotta drive it'? Then take the time to remove the heads, fix the clearances

issues, and put it back together. There is something to be said for putting an engine together in such a

way that it's pure pleasure to live with your own work. (!)

****

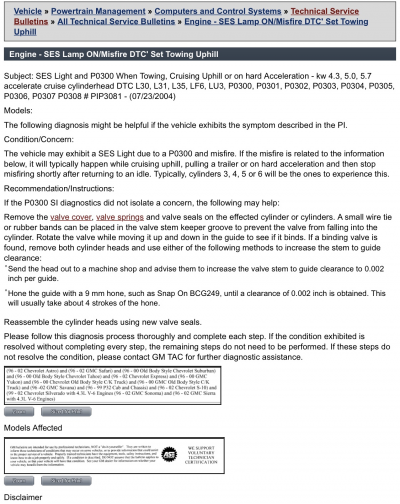

In the 2nd attachment is a TSB (Technical Service Bulletin) where GM addresses the recovery plan for

SBCs that experience misfire during heavy use due to too-tight valve stem/guide clearances.

And in the 3rd attachment is a frame grab from a YouTube video where a machine shop out in Colorado

is taking an engine apart in order to figure out why it only drove 10 miles after being reuilt by a different

machine shop before 'seizing'. Hint: The valve stuck open and the piston kissed it. I think that this video

will give you some insight as to how things go wrong when the valvetrain isn't running the proper clearances.

(

JAMSI 235ci Chevy post-mortem disassembly)

Bonus viewing: Here's the video of the father/son machine shop fixing that same cylinder head, doing it in

such a way as to guarantee a long service life. Great viewing if you've heard some cylinder head terms

thrown about but would like to better understand what your machinist is trying to accomplish: (

old 235 Chevy head machining perfection)

****

So you asked what do I think? Well, a phrase that I've learned from in this forum is "Buy Once, Cry Once."

In other words, "There's never time to do it right...but there's always time to do it over." Actually I'm mixing

metaphors a bit for effect. When it comes to engines, putting something together when it's telling you

that something isn't right is no recipe for long term success.

My elders would tell me to take it back apart and fix the obvious. Schurkey is on the record as saying that

0% leakage through the valves is the standard. GM would tell you in their TSB that too-tight valve

stem/guide clearance will end up setting DTCs for misfires when things heat up, expand, and not seat

properly when the going gets hot. And the machinists in those videos will tell you that they got to rebuild

a rebuilt motor because too-tight valve stem/guide clearances caused a valve to stick open with only

10 miles after a rebuild.

But ultimately it all depends upon what your goals are for your project.

For what it's worth --