I started to hijack a thread but I'm going to be getting into the weeds it looks like so wanted to start another separate thread. Hopefully I can finalize it with results as we apparently have enough cliffhangers around to satiate my appetite for those.

From the other thread

From the other thread

Starting some troubleshooting on my 93 350tbi. About 4 months ago I installed a Delphi FE0114 for reference....

Checking fuel pressure today I'm getting 14psi. Stock spring afaik....

But when I depress the pressure relief button or whatever it's called on the gauge, the fuel pressure drops to 8.

Please tell me the pump isn't the only suspect.

I'm going to start another thread most likely but wanted to ask because I remember Schurkey saying that depressing the button was a way to simulate a load and I'm seeing this behavior.

Pushing the pressure relief button on the fuel pressure tester causes additional fuel to flow, simulating high-load engine demand.

I suppose different fuel pressure gauge assemblies could flow various amounts through the pressure relief. So MAYBE the pressure relief on your gauge flows a huge amount and the pump can't keep up.

But I doubt it.

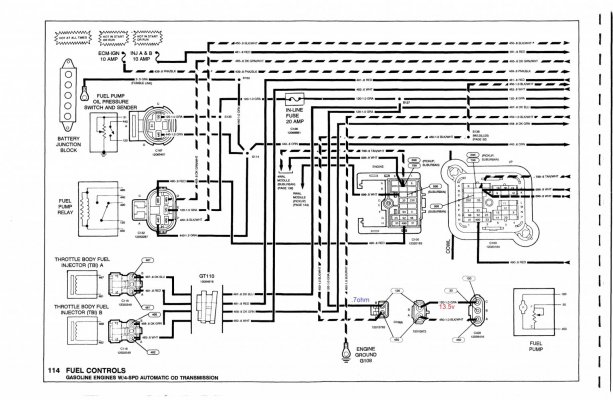

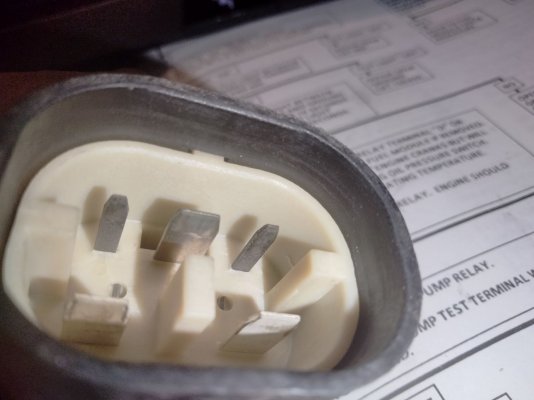

I'd be checking the voltage and amperage as close to the pump as practical, probably the most-rearward connector before the harness goes up 'n' over the tank. (The amperage can be tested anywhere in the circuit, but the voltage has to be tested close to the pump.) The pump MUST be running to test the voltage and amperage.

How old is the fuel filter?

Will do. But scanner showing 13.6v at fuel pump now that truck is running......

My truck randomly died while idling in driveway trying to get my new aldl cable working with my phone. It actually wouldn't start for a bit too. Just cranked... then started working. When I put the scanner on to start looking at stuff I noticed the fuel pump voltage acting flakey when cranking.....drop to 8 volts...showing 10v koeo.... not normal.....

I was paranoid the aldl interface messed something up but I'm guessing just an odd coincidence since truck died after with my normal scanner........

truck not acting up now apart from me noticing the fuel pressure drop. I'm just getting started on looking at things. This issue is going to catch me off guard if I don't get it sorted....

Old enough I guess.....maybe 6 months or more...would have to check......and I never changed it after putting new fuel pump in 4 months ago....

The scan tool CANNOT "show 13.6V at the fuel pump" because there's no voltage sensor at the fuel pump.

The voltage reading is from significantly further forward, where the harness ties into the computer.

You MUST measure voltage as close to the fuel pump as practical, and you can't do that with a scan tool.

Yup, you need to do some tracing and examination of the wire harness with a multimeter. Burnt contacts on the fuel pump relay are somewhat common, and I suppose the same for the contacts in the oil-pressure switch. TEST BEFORE REPLACING

Thank you....

That does make me think more about how I was seeing my oil pressure gauge in the dash acting a bit funny and moving 5 or so psi back and forth...maybe more..... I couldn't see the movement on my mechanical gauge but I never bled the air in that line so I'm not clear how sensitive it is to movement.. It was dramatic enough on the dash to take notice though....

Will investigate more tomorrow... God willing of course...

There is ZERO point to "bleeding air" from oil pressure gauge tubing. It will re-fill with air at every engine shut-down.

The biggest advantage to plumbing the oil pressure gauge with copper tubing, is that they can't see the air inside, and therefore it doesn't bother folks.