L31MaxExpress

I'm Awesome

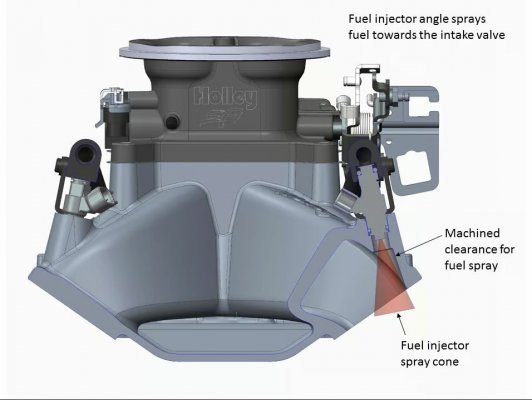

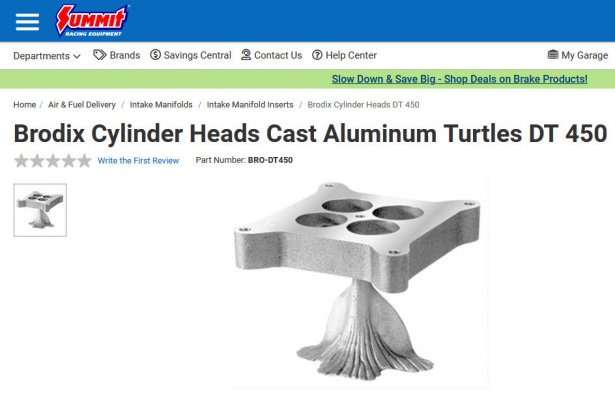

The single plane is probably not the most ideal manifold but I have it and it will be the easiest to adapt. Also have a 103mm throttle body that should allow the 383 to get enough air. I may use the Fitech 92mm, up in the air on that. Parts are an Erson custom grind, Lunati short travel lifters, Holley intake manifold and fuel rails, Holley intake elbow, MSD Atomic 103mm 4 bolt LS throttle body, an EFI connection 24x reluctor and Delco D585 coils on relocation brackets. My intent is to mount the coil packs up front, probably on the inside of the frame itself and run the plug wires down low like a LT1 keeping the coils more away from the heat that cooked them the first time I tried the setup on the old 350. I went away from them when I built the 383. I am ready to have a flex fuel sensor on this that actually works. It ia disabled for some reason on a 4x ignition P59 calibration but works fine on a 24x setup. In theory the smaller, wider LSA, higher lift cam and single plane manifold should broaden the actual torque curve. I would use another dual plane but I am actually trying to kill off some midrange cylinder pressure. Trying to get as flat of a torque curve from off-idle to 6,000 as humanly possible from this little 383. Cam was spec'd and ground with a shorter runner Indmar manifold or single plane as the intended manifold of choice.

You must be registered for see images attach

You must be registered for see images attach

Last edited: