I was looking there too but, IDK what would happen if you kill power to the ECM too. that may reset it every time you kill the pump - maybe not.

This is why I like the way that one of us can make a suggestion, and then it gets kicked around (peer reviewed)

in here. I thought that I had covered the 'continuous power feed for the volatile memory' issue...but upon looking

closer I think I've uncovered an error in the '88 FSM?

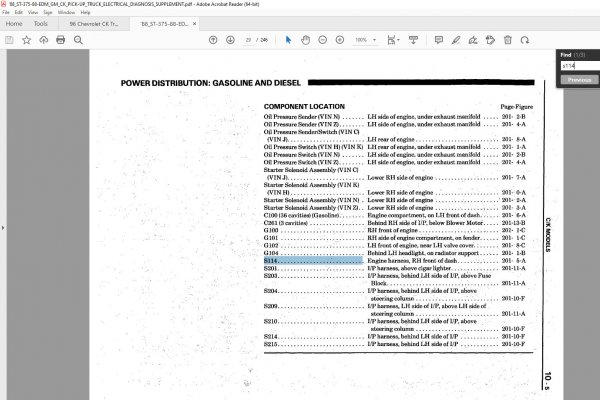

Check this out -- look for the oval where I circled the (documented) input for the continuous battery power:

You must be registered for see images attach

OK, if I take it at face value, Pin A6 on Connector C2 covers the continuous power so that all the local self-tuning (& SES error codes) aren't lost.

And going back to my last post, removing power before splice S114 affects:

* C16 on Connector C1

* B1 on Connector C2

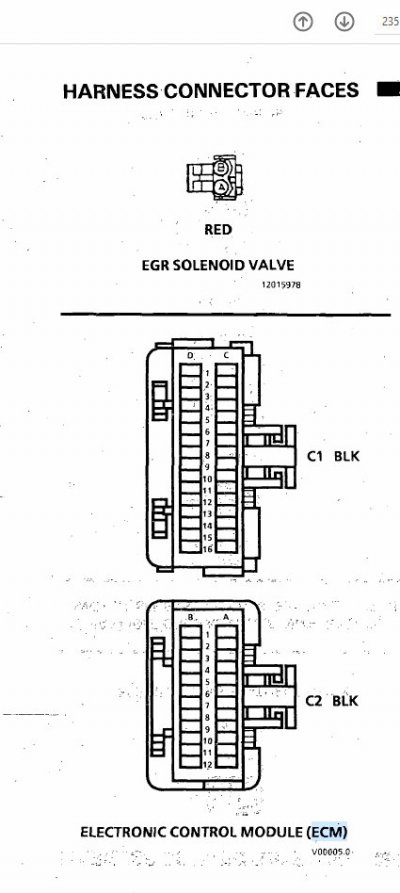

Looking at the ECM connector pinout page (see attached) I saw no conflict, so I posted reply #12.

HOWEVER, based upon your comment I went back and took a closer look. Sure enough, I see an

error in the diagram above. In order to provide the claimed 'continuous battery input for memory'

functionality, Pin A6 on connector C2 must be connected to a "Hot At All Times" wire. (Which is

typically color coded

orange.) But the diagram above is showing a pink/black wire leading back to

a feed from the ignition switch via the ECM/IGN fuse?

****

As Schurkey has mentioned elsewhere, there were so many errors in the new '88 model FSMs that they

subsequently printed a Supplement. Given all this, I'm siding with your proposed solution in reply #15.

And I'm going to leave my reply #12 in place, for I think this illustrates for others that these books are

very good to excellent...but they aren't

perfect. 36 years later there is an irreducible noise floor in these

books, but as long as we pay close attention to this fact, then we can still eventually hammer out a correct

solution.

Summarizing, reply #15 could be implemented with a DPDT switch? (

DPDT switch selection) NOTE: All

wiring for this hidden switch will be entirely inside the cab, reducing weatherproofing issues.

Whew -- learned a lot more in this area than I anticipated. :0)