I hate a working KS! Been chasing knock at 1000-1600 in the 60-80 MAP range. Pulled timing out three times and still the same affect with no reduction in knock. I'm beginning to think it's picking up the rod knock in that old boat anchor. Think I'm just going to turn it back off for now and go back to the ear sensor.

This can't be so much timing as to cause knock,

I'm assuming that you are tuning for 87 octane? I've found myself in a similar situation,

where I was having trouble figuring out if the knock was due to my tuning being too aggressive,

or if it was an underlying mechanical issue?

I've found that running the tank close to empty, adding 2-3 gallons of 93 octane, and retrying

my test was informative. If my timing curves were just a little too much of a good thing, then

the higher octane gas would clear up the pinging/knocking.

On the other hand, if the high test didn't make a difference, then I knew the root cause was

due to a mechanical issue. More octane won't fix excessive clearances. :0)

And before I knew enough to pay close attention to deck height & target a tight quench it

seemed that a sharp tune was kinda squishy. I didn't know if it was fuel distribution, or

a geographical heat distribution issue, but it always seemed like 1 cylinder start audibly complaining

first, so the most 'knock-sensitive' cylinder would set how much of a tune all 8 would get?

I remember when I had my first engine zero-decked, and set everything up for a tight quench.

When I went to tune this engine, it was

so much easier. Instead of just 1 cylinder getting noisy

first, all 8 would be protesting in unison -- or all 8 would be quiet & pulling hard. (It's like the

valvetrain - an engine with 1 loose rocker arm & 15 correct sounds completely different than

the same engine with all 16 rocker arms loose. The former is an individual clonk clonk clonk

that stands out from the crowd, while the latter is a more uniform, 16x faster clatter.)

Same thing with 1 cylinder knocking vs all cylinders knocking in unison.

Of all the theoretical engine stuff I've chased and got minimal returns on the time &

money invested, the whole squish/quench thing was one area that really delivered a

difference in the real world.

That and oil control -- once I read that air/fuel/oil has a lower octane rating than the

same air/fuel charge that's oil free, this explained a lot of weird tuning issues I had worked

on in the past with no clue as to why this older, oil consuming engine wasn't happy with my

tuning recipe? :0)

****

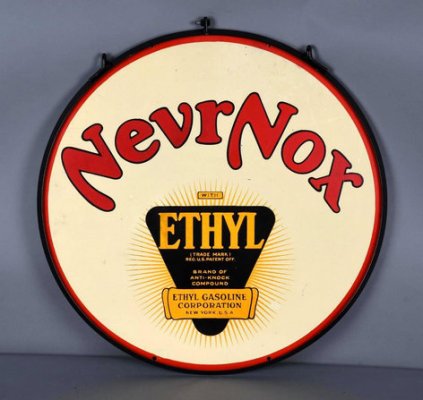

Apologies for the length, but your comments about the working KS vs suspected rod

knock triggered some memories. A lot of the mystery issues that we used to cover up

by running Ethyl or Avgas is now much better understood thanks to the desire by all

involved to make big, reliable power on today's lower octane fuels.

Your writing on this tuning effort is really interesting. I'm looking forward to seeing

where you eventually end up with all this. Good stuff.