RollinTurd

Newbie

Hey folks! Dont post much, but sure do learn a lot from all the other posts. Ive got an 88 C1500 5.7 with 190K on the clock. Also running EBL Flash II. Trans was slipping in lockup and had it rebuilt recently by a reputable local shop less than 100 miles ago. Overall, very pleased with the transmission. Got some upgraded parts in preparation for my 383 if that day ever comes.

Issues:

1. EBL Flash II no longer recognizes the gear that the tranny is in. Prior to rebuild would show P, N, D, and OD.

-EBL shows 0 for gear indicator

-How did the ECM know which gear the tranny was in??

2. Lockup only works in 4th, and seems to be on a short time delay engagement.

-had lockup in 3rd and 4th before rebuild

-lockup would disengage with engine load before rebuild not after

-lockup indicator in EBL Whats Up Display does not match what the tranny is actually doing

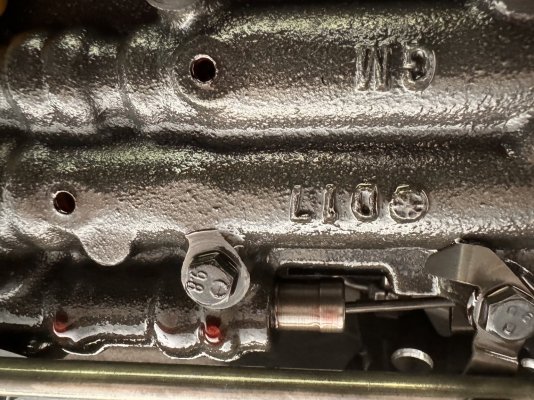

3. I think i got my transmission back, but not 100% sure.

-Going to check the codes per Nick's writeup to see if its close

-Any other ways to tell?

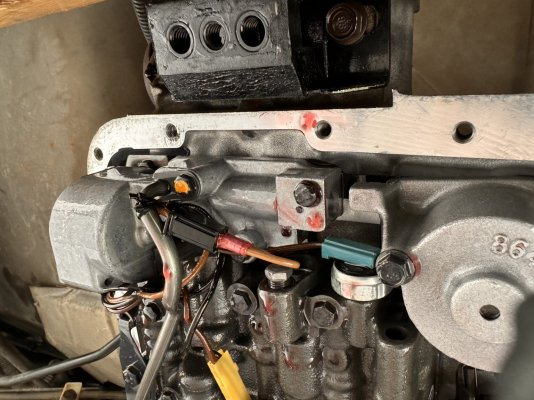

Talked to my transmission guy today to ask if any changes were made to alter lockup, and he said the only thing he changed was adding a jumper wire over the lockup temp switch.

Hoping one of you or @NickTransmissions can shed some light on this or give some ideas of where to start. I know I'm probably going to have to drop the pan but want to avoid it if possible. Should have went with a plugged drain pan...hindsight...

Issues:

1. EBL Flash II no longer recognizes the gear that the tranny is in. Prior to rebuild would show P, N, D, and OD.

-EBL shows 0 for gear indicator

-How did the ECM know which gear the tranny was in??

2. Lockup only works in 4th, and seems to be on a short time delay engagement.

-had lockup in 3rd and 4th before rebuild

-lockup would disengage with engine load before rebuild not after

-lockup indicator in EBL Whats Up Display does not match what the tranny is actually doing

3. I think i got my transmission back, but not 100% sure.

-Going to check the codes per Nick's writeup to see if its close

-Any other ways to tell?

Talked to my transmission guy today to ask if any changes were made to alter lockup, and he said the only thing he changed was adding a jumper wire over the lockup temp switch.

Hoping one of you or @NickTransmissions can shed some light on this or give some ideas of where to start. I know I'm probably going to have to drop the pan but want to avoid it if possible. Should have went with a plugged drain pan...hindsight...