Probably the fuel pump, eh?Fuel pressure, resolve that. As Schurkey and someotherguy pointed out, ~20psi is too low.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[SOLVED] 1995 k2500 7.4 TBI running HORRIBLY

- Thread starter Cuckfield

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

someotherguy

Even more awesome in person

Start with confirming pressure, if it's low, replace the filter.Probably the fuel pump, eh?

Richard

grampadirt

On MEDICARE Officially Old

Consider replacing the ICM(ignition control module),you'll find it in the distributor.I've had similar problems with my '95 Burb and replacing the ICM would solve them.If you do replace it be sure to use an ACDelco part and nothing else.I recently had problems with wifey's '99 Burb and tried two Delphi ICMs and both were bad,put an ACDelco in it and it fired right up.

Word. Just replaced the filter yesterday before making this post. I took my readings after replacing filter.Start with confirming pressure, if it's low, replace the filter.

Richard

I'll give this a shot, thanks.Consider replacing the ICM(ignition control module),you'll find it in the distributor.I've had similar problems with my '95 Burb and replacing the ICM would solve them.If you do replace it be sure to use an ACDelco part and nothing else.I recently had problems with wifey's '99 Burb and tried two Delphi ICMs and both were bad,put an ACDelco in it and it fired right up.

DerekTheGreat

Forum Regular

Fuel pressure first, you've got data on that. Fire the parts cannon again if that doesn't fix it.

That probably rules-out a slipped damper, mis-matched damper/timing pointer set, and a faulty timing light.No, I did not have to turn the dizzy.

Of course. You'd need an appropriate scan tool with suitable software, and the connector cable. Some guys go for the laptop/smartphone, software, and connector cable. I prefer an actual scan tool to a scan tool simulation.Can you read a '95 with an obd1? I always hear you can't.

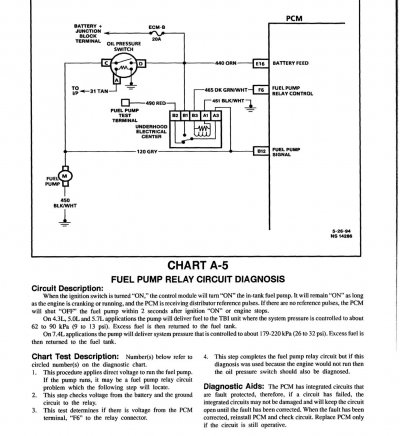

VERIFY VOLTAGE at the fuel pump. More is better--within a volt or two of system voltage. Measure as close to the pump as practical--generally the rearmost connector in the harness before the harness goes up 'n' over the tank. The pump MUST BE RUNNING when you check voltage. ALSO, verify voltage on the ground wire for the fuel pump. Again, pump must be running, and test as close to the pump as practical. Less is better.I will double check and re-verify fuel pressure tomorrow.

You can replace the pump a hundred times, and still have low fuel pressure if the pump is starving for power.

Sorry, I've never messed with multimeters/electronic stuff before; how can I verify fuel pump voltage?That probably rules-out a slipped damper, mis-matched damper/timing pointer set, and a faulty timing light.

Of course. You'd need an appropriate scan tool with suitable software, and the connector cable. Some guys go for the laptop/smartphone, software, and connector cable. I prefer an actual scan tool to a scan tool simulation.

VERIFY VOLTAGE at the fuel pump. As close to the pump as practical--generally the rearmost connector in the harness before the harness goes up 'n' over the tank. The pump MUST BE RUNNING when you check voltage.

You can replace the pump a hundred times, and still have low fuel pressure if the pump is starving for power.

On my 93 there is a 3way harness back by the gas tank that goes to the fuel pump. The gray wire is where you want to see the pump voltage with truck running. Yours looks to be gray as well.Sorry, I've never messed with multimeters/electronic stuff before; how can I verify fuel pump voltage?

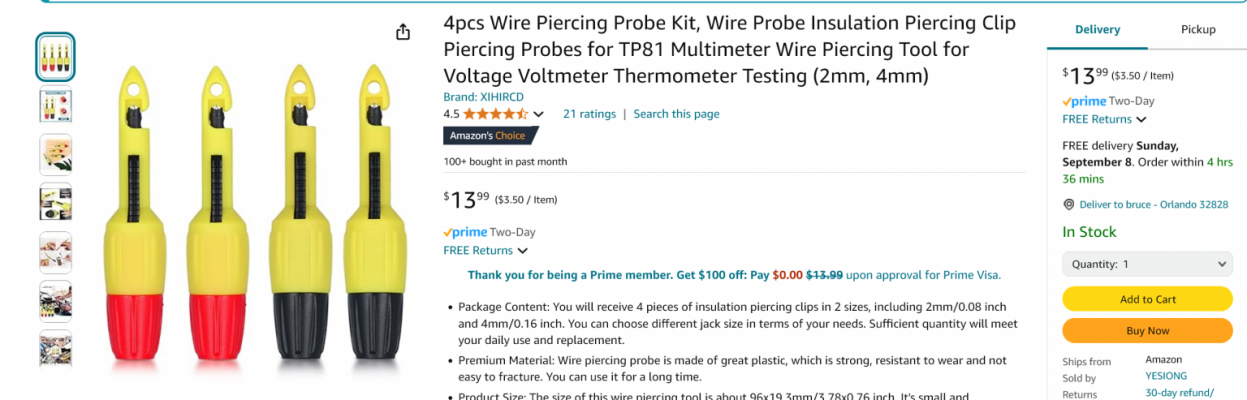

Kinda a pain to get a meter onto the wire to test. I ended up stripping some insulation back but wish I hadn't. Have since bought the piercing ones in the pic below...haven't used them yet but they look like they will work great.

You put your meter to dc volts in the range you want it to be. My meter has a 20 volt setting so I use that...

Put the red lead on the gray wire, and the black lead to ground. There is a ground wire and screw that goes into the frame right next to my harness. Can use that if you have same.

Might want to verify that ground is good first....

or run a jumper wire....jumper cable could work, from battery negative back to where you are with the meter....and hook your black meter lead to that for a ground.....

Attachments

You need a DC voltmeter--which will probably be part of a multimeter including AC and DC volts, Amperes to about 10 amps, several Ohms ranges, perhaps capacitance, perhaps a "battery testing" (AAA, AA, C, D, 9-volt) set of ranges which puts a small load on the battery when testing it's voltage, that sort of thing. Features vary with the meter selected. There's a million choices, and almost all of them are going to be cheap Chinese even if they're not inexpensive.

You will need either fine-wire "back probes", or a "test harness" that you can pierce the insulation and not damage the actual vehicle harness. The "back probes" may or may not be included with the meter you buy.

You'll turn the meter on, and select a DC voltage range that's as low as it goes and still accommodates 15 volts. On MY meter, that's the 40-volt scale, but other meters might have a lower voltage range--20 or 24, perhaps. A 6-volt scale won't accommodate 15 volts, so that's too low.

Testing the power supply TO the pump will require grounding the black meter probe, (preferably at the negative battery terminal, using a length of ordinary primary wire as needed) while sliding the red back-probe pin into the connector, past the silicone-rubber seal, so that the back-probe contacts the metal pins of the connector, and the meter is connected to the back-probe pin(s). You'd probably run the engine at this point, so that the pump is running, and you'd read the voltage on the meter. The alternator is likely charging at 14+ volts, so you'd better have 12.0 volts or more, showing on the meter. Remember, you're not testing the harness between your test point and the actual pump--the harness going up and over the tank, and the in-tank harness. A problem there is "invisible". But this is the best you can do without damaging the vehicle harness or dropping the tank/lifting the bed.

When testing the ground side, you'd do essentially the same thing. Ground the negative lead. Touch the red probe to the ground wire conductor as close to the pump as you can reach. This will require piercing the insulation of that wire, and you'll have to "patch" the insulation with something--"liquid electrical tape", real electrical tape, a dot of RTV silicone, etc. You're looking for the lowest value--under one volt, less is better.

You will need either fine-wire "back probes", or a "test harness" that you can pierce the insulation and not damage the actual vehicle harness. The "back probes" may or may not be included with the meter you buy.

You'll turn the meter on, and select a DC voltage range that's as low as it goes and still accommodates 15 volts. On MY meter, that's the 40-volt scale, but other meters might have a lower voltage range--20 or 24, perhaps. A 6-volt scale won't accommodate 15 volts, so that's too low.

Testing the power supply TO the pump will require grounding the black meter probe, (preferably at the negative battery terminal, using a length of ordinary primary wire as needed) while sliding the red back-probe pin into the connector, past the silicone-rubber seal, so that the back-probe contacts the metal pins of the connector, and the meter is connected to the back-probe pin(s). You'd probably run the engine at this point, so that the pump is running, and you'd read the voltage on the meter. The alternator is likely charging at 14+ volts, so you'd better have 12.0 volts or more, showing on the meter. Remember, you're not testing the harness between your test point and the actual pump--the harness going up and over the tank, and the in-tank harness. A problem there is "invisible". But this is the best you can do without damaging the vehicle harness or dropping the tank/lifting the bed.

When testing the ground side, you'd do essentially the same thing. Ground the negative lead. Touch the red probe to the ground wire conductor as close to the pump as you can reach. This will require piercing the insulation of that wire, and you'll have to "patch" the insulation with something--"liquid electrical tape", real electrical tape, a dot of RTV silicone, etc. You're looking for the lowest value--under one volt, less is better.

Trying to visualize this..."test harness" that you can pierce the insulation and not damage the actual vehicle harness

got a pic?

Similar threads

- Replies

- 3

- Views

- 234

- Replies

- 1

- Views

- 777

- Replies

- 13

- Views

- 1K

- Replies

- 12

- Views

- 740

- Replies

- 7

- Views

- 1K

Members online

- 97GMCC2500SLE

- ynot5903

- 94 Sub

- South VA

- tardisguy

- Carlosthehandyman

- PlayingWithTBI

- Striker1423

- 1997

- Carlaisle

- El Tigre

- 1 slow 84 chevy

- Ozzy4194

- Badcraig

- Tim W

- Charlesteneows

- _W1N_

- Ckt93

- RonSoCal

- fancyTBI

- Hammersmith

- Sle-z_90

- Road Trip

- johnckhall

- Drunkcanuk

- klzeturbo8

- mxkinn01

- 92yukon

- npme99

- Ebrogan05

- Rob-tie

- nightfire37

- Christmastree Burb

- lj502

- Off Grid Access

- dragnazz

- Robert Jelen

- Klassen

- 97c1500themistress

- wilburou812

- dmage

- Joe Guldan

- audilowksta

- Notjoken

- dotwell69

- razzle

- GONE_FLAT

- strikk

- BNielsen

- solaralexx

Total: 1,954 (members: 80, guests: 1,874)