Update:

Pulled the starter and did a bench test myself - got it to engage with no problems using jumper cables and a battery. (Bummer - I was hoping this would be the obvious problem)

Alright. I like the fact that you are willing to test vs just throwing a new starter at it.

OK, the key to understanding what we're observing is keeping track of the variables.

1) Using the jumper cables instead of your truck's power cables is a variable.

2) Was the battery you used the same exact one in the truck, or just another 12v battery in your shop?

But you were able to get this starter to operate while out of the truck, but not in the truck, on an engine with

the plugs out & can be turned over by hand? Hmmm...

Reinstalled the starter and tried jumping over the switch in the same way that I bench tested it. (I know, a little redneck, but I’m getting slightly impatient). Jumping it with a screwdriver while the ignition is in the off position (and again with key in run position) resulted in same “Ping - dead” effect. I had my son quickly disconnect and reconnect the battery after everything went dead and that brought the power back on right away.

You know, I absolutely believe you when you share these observations, but the problem I'm having is that

*I* currently can't explain this behavior using just the wiring circuitry documented in the Factory Service Manual?

Q: At this point I'm wondering if there is some remnant of an aftermarket anti-theft device still connected to

your truck? Adding an anti-theft device to these trucks was a pretty popular thing to do back in the day?

(I've been trying to reason through how the headlights are being shut off after an attempted cranking, and not

being able to explain to my satisfaction how these symptoms are occurring?)

While I was laying under the truck with my redneck screwdriver, I noticed that it sure seemed like the “Ping” sound was coming from the starter.

Can a starter engage with no load and falter like this when put under load? Will a parts store do more extensive testing on a starter to reveal something deeper? I still need to take the battery in to get it load tested…

The saga continues! Thanks guys!

Now that we know that your starter has demonstrated the capability to operate, I'd like to stop

here and explain getting a starter to spin is actually a discrete 2-step process. (Normally I don't

drag folks through this, but since it sounds like your starter is getting stuck inbetween these

2 steps I'd like to discuss this further.)

OK, having the electrical wiring diagram that we used earlier to analyze the starter relay may be

helpful.

Step #1: We turn the key to start, and power is fed from a 40A fuse, through the starter relay,

and to the starter

solenoid. Thanks to all the windings in the solenoid acting as an electromagnet when

current is applied, the center plunger inside the solenoid is pulled towards the power cables we've

connected to the starter. (ie: Towards the front of the truck.)

At the end of it's travel is a high current connector...and when that connector hits the contacts,

the big current from the 2 gauge positive cable is going to be coupled directly to the

starter *motor*. Spinning will immediately commence.

**

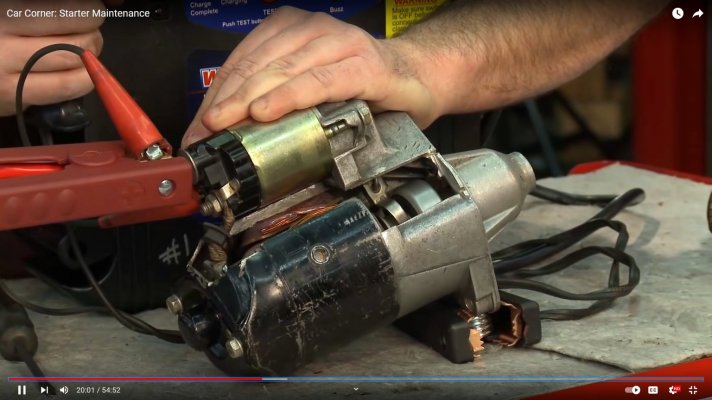

Meanwhile, thanks to a pivot, this plunger hurtling towards the power cables is going to throw the

starter's pinion gear in the

opposite direction towards the flywheel. Study this photo and see if you can

visualize all this movement:

You must be registered for see images attach

(credit: '67-'72 chevytrucks.com --

How our starters work)

Now here is an important detail. We need to fully mesh the starter pinion

with the flywheel/flexplate's ring gear

before it starts spinning, or else

we are going to chew up the teeth in short order. So what this design

does is first throw the non-spinning starter gear hard and fast into a fully

meshed position with the flywheel, and up to this point ALL of the work has

been accomplished by the smaller purple wire. This is key.

Step #2: Now when you got the starter to operate, what happened is once the

starter solenoid plunger got everything fully extended, the "heavy duty"

contacts are firmly connected. And since those jumper cables gave you

the full current when you tested it on your bench, the starter started

spinning. (Instead of Ping > quiet, we get Ping > Spinning)

THIS is where we're coming up short in your truck. The Ping is the sound

of the solenoid throw, but the lack of rotation from the starter *motor* is

the deafening silence afterwards.

I don't know if your truck's battery has the inability to deliver the

necessary current, or your battery is OK, but either the high current

ground or power cable has excessive internal resistance. (Due to corrosion,

or broken individual wires, or some combination of the 2?)

NOTE: If you 'starve' the starter solenoid for current due to a marginal path,

as a troubleshooter I could make the argument that the lack of current doesn't

allow the starter solenoid to fully extend all these moving bits against the return

spring? And since the "heavy duty" contacts are never closed, the starter motor

never gets the power needed for spinning. But thanks to your latest 'in truck'

troubleshooting via the screwdriver method...and this didn't change the behavior,

so the problem is not the wiring from the starter relay? (!)

****

But this same trick worked on the bench! Thanks to your troubleshooting

efforts, I think we're on the cusp of figuring this out.

1) Your starter worked on your bench. If did NOT work either before or

after in the truck.

2) Using the jumper cables that worked on the bench, can you temporarily substitute

these into your truck? One jumper cable supplying the ground to the block,

the other cable supplying the 12v to the starter motor instead of the 2 gauge cable?

Let's say that the jumper cables get the starter to work in the truck. One at a time,

disconnect the positive jumper and see if it still works? If it doesn't, Voila! it's a

bad starter power cable. If it still works, then disconnect the negative jumper cable

and retest.

****

And what if the jumper cables don't change the behavior? Then if you used a different

battery on the bench check, we have narrowed it down to something goofy in the

truck's battery. And now it's time to take this battery somewhere for a definitive

load test.

****

I apologize for the length of this reply, but this is the level we have to think when

your starter works on the bench, but it won't work on the truck. Assuming that

you have a good battery, + good positive & negative 2 gauge cables, and a

good starter, then your minimalist screwdriver test *has to work*, whether in

the truck or on the bench. (!)

It's just a matter of figuring out which variable is the one that's the root cause of your "Ping, no crank" scenario.

I am looking forward to your next update. Hope this helped explain why bench good, truck bad.

Happy hunting --

**(Optional viewing)

This YouTube video gives a good demo of what all this physical movement looks like

thanks to them cutting viewports into a working starter. If you skip to the ~19:55 spot

in the video you can get right to the good stuff: (

Starter Operation Demo)

X2…this forum is lucky to have

X2…this forum is lucky to have