You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'98 C1500 5.0L RWD No start

- Thread starter James2406

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

alright, jumper in, MAF in, starts and runs, and if I remove the MAF while it's running, it trys to die.

oddly enough too, I removed the jumper and it ran for a solid minute where as before it instantly died, got worried it was running away for a minute lol

oddly enough too, I removed the jumper and it ran for a solid minute where as before it instantly died, got worried it was running away for a minute lol

oddly enough too, I removed the jumper and it ran for a solid minute where as before it instantly died, got worried it was running away for a minute lol

Most folks aren't aware that there is not 1 but 2 power sources for the fuel pump. The first source

is the fuel pump relay, but your engine Oil Pressure switch is connected in parallel, and also supplies

power to the fuel pump as long as the oil pressure is greater than 4 psi:

You must be registered for see images attach

Given the way this circuit is wired, if the key is on & you were to remove the jumper from the fuel pump

relay socket while the engine is running, then if your backup oil pressure switch is functional then I would

expect the pump to stay on, the fuel pressure remain steady, and the engine continues to run.

By the time you get done troubleshooting this issue, you will know a lot more about this circuit

than when you started. Never a bad thing. :0)

****

Now to figure out how to get that fuel pump to run just as steady through the

relay being controlled by the VCM.

In order to quickly figure out which of the 2 scenarios we are currently dealing with:

* Solid VCM trying to control flaky Fuel Pump Relay

vs

* Solid Fuel Pump Relay being controlled by a flaky VCM

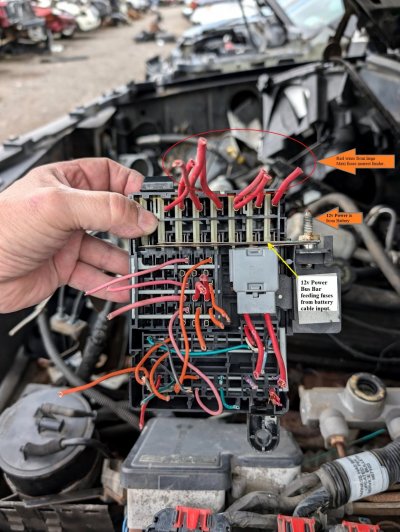

Good news: In the attached photo the 4 square relays on the left are identical.

IF we think that the Fuel Pump Relay is flaky, we can swap positions with one

of the others and see if the bad behavior moves with the relay or stays with

the socket. (And while you are in here, make sure that the relay socket connectors

aren't a loose fit after being jarred by a million potholes since it was built.)

NOTE: A flaky fuel pump relay is *not* going to trip all those DTCs, but I'm just

trying to quickly add the fuel pump relay to the proven-good pile of parts.

(Currently fuel pump & injection system.)

So give this a try and let us know what you observe.

Attachments

Last edited:

So only once out of about five times was the truck able to stay running with the jumper removed, all other times it immediately stalled.Most folks aren't aware that there is not 1 but 2 power sources for the fuel pump. The first source

is the fuel pump relay, but your engine Oil Pressure switch is connected in parallel, and also supplies

power to the fuel pump as long as the oil pressure is greater than 4 psi:

You must be registered for see images attach

Given the way this circuit is wired, if the key is on & you were to remove the jumper from the fuel pump

relay socket while the engine is running, then if your backup oil pressure switch is functional then I would

expect the pump to stay on, the fuel pressure remain steady, and the engine continues to run.

By the time you get done troubleshooting this issue, you will know a lot more about this circuit

than when you started. Never a bad thing. :0)

****

Now to figure out how to get that fuel pump to run just as steady through the

relay being controlled by the VCM.

In order to quickly figure out which of the 2 scenarios we are currently dealing with:

* Solid VCM trying to control flaky Fuel Pump Relay

vs

* Solid Fuel Pump Relay being controlled by a flaky VCM

Good news: In the attached photo the 4 square relays on the left are identical.

IF we think that the Fuel Pump Relay is flaky, we can swap positions with one

of the others and see if the bad behavior moves with the relay or stays with

the socket. (And while you are in here, make sure that the relay socket connectors

aren't a loose fit after being jarred by a million potholes since it was built.)

NOTE: A flaky fuel pump relay is *not* going to trip all those DTCs, but I'm just

trying to quickly add the fuel pump relay to the proven-good pile of parts.

(Currently fuel pump & injection system.)

So give this a try and let us know what you observe.

I have swapped every relay that was identical around, and all of them click, etc.

I was looking around the fuse box, and need to find out how to disassemble it, and see if I can maybe manually attach the really to each individual wire or check and see if the wires in the socket themselves have come loose or broken.

So only once out of about five times was the truck able to stay running with the jumper removed, all other times it immediately stalled.

I wouldn't be the least bit surprised if your oil pressure switch is flaky/intermittent. Although this is not the priority,

it would be savvy to have that backup strategy working as well. Not that important if the owner just drives it to the

dump and stays close to home, but well worth it if he takes it on long road trips.

I have swapped every relay that was identical around, and all of them click, etc.

That's pretty much what I expected. The relay is OK, and via the jumper you have also proved

that the orange power in and gray power out paths are good. So now we're down to the control

coil side of the relay. (ie: The control signal from the VCM, as well as a solid ground connection on

the far side.)

I was looking around the fuse box, and need to find out how to disassemble it, and see if I can maybe manually attach the really to each individual wire or check and see if the wires in the socket themselves have come loose or broken.

I like your idea. But I would ask you to first disconnect the negative from the battery so that you

don't accidentally arc anything with the "Hot Always" red & pink wires. (!)

I've attached 3 photos just to give you an idea of what you are going to find. Once you've

disconnected the main battery you will find that the fuse block can be easily split in 2. But

you first have to disconnect the main power into this fuse block at the back in order to

completely split this apart.

Looking forward to your next status report.

Be careful -- no sparks.

Sincerely, Sparky :0)

Attachments

Last edited:

I found no melted or frayed wires, but I did find two connectors not plugged in, not sure what they go to, but they both seem to be female.

I did follow this diagnostic table,

But it just tells me to replace the TPS, which I have done already. And the truck will not run.

Also,

When instructed to test the 5 volt reference with multiple ground locations tested, including the thermostat ground, and even the battery ground, I get a OL open loop on my multimeter, where as sockets B & C give a small voltage read out. Don't know if that is related.

You must be registered for see images attach

You must be registered for see images attach

I did follow this diagnostic table,

You must be registered for see images attach

You must be registered for see images attach

But it just tells me to replace the TPS, which I have done already. And the truck will not run.

Also,

You must be registered for see images attach

When instructed to test the 5 volt reference with multiple ground locations tested, including the thermostat ground, and even the battery ground, I get a OL open loop on my multimeter, where as sockets B & C give a small voltage read out. Don't know if that is related.

Last edited:

Found this on reddit about a '96 5.7 truck,

Important question once the engine is running and you remove the jumper will it stay running?

The way that system operates is simple. Turn on the key, the system should prime for about 2 seconds, then the engine starts and you get oil pressure. As soon as the oil pressure is over 18 psi the oil pressure switch toggles on and powers the fuel pump. The relay at this point isn't really a factor. So if it stays running without the jumper the oil pressure switch and wiring is OK, if not check that first.

Now assuming it does run you need to diagnose why the relay isn't switching to prime the system, Is it lack of a ground to the coil or lack of switched power from the PCM? Is it simply a bad relay?

For the power and ground to the relay grab a test light. Connect it to battery pos. Now touch it to the relay socket on terminal 86. Does it light up? Yes ground is OK, No, ground is broken (Black wire with white)

Now connect it to battery neg. and touch it to terminal 85 in the socket, have someone turn the key on, does the light come on for a couple seconds? Yes signal from PCM is OK, no broken wire from PCM (Con 4 pin one Dk Green/white wire) or bad PCM.

If testing shows things are OK, replace the relay.

With my test light attached to the positive on the battery & socket 86, It illuminates. According to this redditor it indicates good ground. When I test from the negative terminal to the socket 85, I get no ilummination. Bad VCM wiring?

Important question once the engine is running and you remove the jumper will it stay running?

The way that system operates is simple. Turn on the key, the system should prime for about 2 seconds, then the engine starts and you get oil pressure. As soon as the oil pressure is over 18 psi the oil pressure switch toggles on and powers the fuel pump. The relay at this point isn't really a factor. So if it stays running without the jumper the oil pressure switch and wiring is OK, if not check that first.

You must be registered for see images attach

Now assuming it does run you need to diagnose why the relay isn't switching to prime the system, Is it lack of a ground to the coil or lack of switched power from the PCM? Is it simply a bad relay?

For the power and ground to the relay grab a test light. Connect it to battery pos. Now touch it to the relay socket on terminal 86. Does it light up? Yes ground is OK, No, ground is broken (Black wire with white)

Now connect it to battery neg. and touch it to terminal 85 in the socket, have someone turn the key on, does the light come on for a couple seconds? Yes signal from PCM is OK, no broken wire from PCM (Con 4 pin one Dk Green/white wire) or bad PCM.

If testing shows things are OK, replace the relay.

With my test light attached to the positive on the battery & socket 86, It illuminates. According to this redditor it indicates good ground. When I test from the negative terminal to the socket 85, I get no ilummination. Bad VCM wiring?

Similar threads

- Replies

- 98

- Views

- 6K

- Replies

- 4

- Views

- 245

- Replies

- 5

- Views

- 702

Members online

- BuiltToWork

- Badcraig

- Charlesteneows

- Carlosthehandyman

- Carlosm86

- South VA

- fancyTBI

- Skinns1234

- GMT430

- Road Trip

- Cadillacmak

- johnckhall

- Drunkcanuk

- Miahjoe

- PlayingWithTBI

- 94 Sub

- Ozzy4194

- lj502

- 97GMCC2500SLE

- ynot5903

- tardisguy

- Striker1423

- Carlaisle

- El Tigre

- 1 slow 84 chevy

- Tim W

- _W1N_

- Ckt93

- RonSoCal

- Hammersmith

- Sle-z_90

- klzeturbo8

- mxkinn01

- 92yukon

- npme99

- Ebrogan05

- Rob-tie

- nightfire37

- Christmastree Burb

- Off Grid Access

- dragnazz

- Robert Jelen

- Klassen

- 97c1500themistress

- wilburou812

- dmage

- Joe Guldan

- audilowksta

- Notjoken

- dotwell69

Total: 2,107 (members: 71, guests: 2,036)