Maybe one of the lifters on #8 isn't pumping up, giving you a tighter window of adjustment?

(From OP's reply #14)

I installed 8 new melling nuts on the passenger side set the lash it’s quiet now ! But what I realized this time when inspecting the noise ‘ the very

( Last rocker) was loose ? It skipped down the line in some way.

Upon the install of all the new nuts it was hard to define where the noise was coming from until I got to the last Passenger rocker in back and torqued that until it became perfectly quiet .

(From OP's reply #58 yesterday)

For Some reason the compression came back and from there I clockwised the turns again until it stopped making noise super slowly 10second in between turns for catch up - I don’t do huge turns super super small turns for the lash and to ( hear) each rocker quiet down to nothing so small of turns can’t even give them a count. I only do the pre load as a counted turns.

It’s running great now smooth power no noises...

I was really happy to read that the OP has regained control over the engine. But after reading what fixed the noise

I was wondering to myself the same thing that Erik wrote? You see, hydraulic lifters going noisy boil down to

failures in one of these these 3 main categories:

1) Exterior -- the bottom develops excess wear = audible excess clearances. No fix except replacement of all parts involved. (!)

2) Interior -- varnished bore causes plunger to stick, can no longer dynamically adjust valvetrain clearances = noisy solid-lifter-like operation results.

3) Interior -- dirt/grit/foreign object interferes with plunger check ball operation. (hydraulic diode) The ability to use engine oil

pressure to take up valvetrain clearance is now lost, so again the hydraulic lifter becomes the root cause of noisy operation.

So what Erik is proposing is #3 -- the lifter in the way back (#8 exhaust?) collapsed. This in turn gets adjusted while collapsed

& is now quiet. Dirt/foreign object finally clears the check ball, which reseats, the plunger starts working again, and *now* the

overadjusted/too long lifter assembly results in the valve hanging open = zero compression in this cylinder. When the OP

goes back in and makes the readjustment post debris clearing, now it's working again. This is my working theory.

Note: For a great take on recovering from collapsed lifters, read @grampadirt's recent thread: (Collapsed lifters in big block suburban)

****

To replace a dead/broken part, you only need to know the R&R (Remove & Replace) procedure.

But in order to troubleshoot a noisy part that's still somewhat operational, you have to know

enough of the underlying theory in order to reason through what the engine is showing you.

So IF the problem returns, I want A97obs to be able to continue the troubleshooting process

all the way to a permanent fix. (In other words, if the problem never returns, then there's no

need to wade through the following. :0)

****

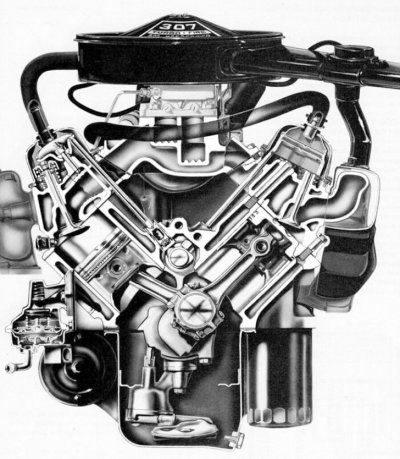

While reading the following, refer to this big picture cutaway view of the internals of a SBC:

You must be registered for see images attach

(Modern drawing taken from an old 307ci SBC black & white cutaway illustration -- see attached.)

First off, now that you've adjusted those rocker arm nuts with a sharp focus, check out this cutaway view

and visualize how tightening/loosening the rocker arm nuts can affect everything in the valvetrain, from the

plunger inside the lifter on one side to opening the valve spring/valve itself on the other.

But as nice as that cutaway is, we need to take a closer look at the individual parts inside our

hydraulic lifters. (Note: Both flat tappet & roller versions share similar internals.) Here's a older

GM exploded diagram of a modern hydraulic lifter:

You must be registered for see images attach

I'd like the reader to stop here so that we can focus on the 2 internal areas that most often lead to noisy (intermittent or continuous)

hydraulic lifter operation. First find the PLUNGER. If the PO used a non-spec oil that couldn't handle the heat, then varnish

would build up upon the inside of the lifter body, trapping/immobilizing the plunger so that it couldn't move up or down internally

as needed to take up the lash. (Our engine blocks and cylinder heads grow/shrink several thousandths of an inch during a typical

heat cycle, so the plunger needs to be able to move in unison in order to keep the peace & quiet.)

Unvarnishing the insides of the lifters with their elixer of choice (Marvel Mystery Oil, Sea Foam, ATF, etc) is

how the elders would work their mojo to fix an older, clattery due to varnish motor. I was a bit of a skeptic that

this is what really fixed sticky lifters. That is, until the first time I fixed my used $350 Olds 425 (whole car,

not just the motor :0) by spending a weekend sequentially disassembling each of the 16 lifters, cleaning the

bits in a carburetor dunk tank, and putting them back together.

What I learned from that project was that they are such close-tolerance devices that it doesn't take much

varnish at all to turn them into solid lifters. (!)

The 2nd part I want you to find is the Check Ball & the tiny associated check spring. There's a (unseen)

hole in the base of the plunger that the check ball seals thanks to the associated spring. Now because

of all the movement varnish is not really a thing here. BUT gritty/dirty oil *is* a big deal. It doesn't

take that much dirt/debris to get inbetween the ball & it's seat to cause the lifter to collapse. So instead

of the plunger being stuck inside the lifter body as described above, instead the plunger moves to the

bottom of the lifter body as the cam lobe starts the lifter body > plunger > pushrod > rocker arm > valve

movement. Visually, a collapsed lifter looks just like it sounds.

If you are comfortable with the 3 paragraphs above, then congratulations -- you are officially a 1%er.

For 99 out of 100 normal people have no idea how a hydraulic lifter uses incompressible oil, a spring-loaded

check ball as a hydraulic one-way valve, and some associated bits in order to keep the peace and quiet in

the engine bay. :0)

****

If a picture is worth a 1000 words, and a video is worth 10,000 words, then please allow me to

cheat and ask anyone still reading to watch this short hydraulic lifter animation. (About 30

seconds in you will see a pushrod setup -- the point is, the hydraulic internals are very similar

no matter if you have a pushrod, OHC, DOHC, etc.)

xc_hide_links_from_guests_guests_error_hide_media

****

Bringing all this back to Erik's query in the beginning, it's quite possible that between

changing drivers as well as engine oils, you may have shook loose some accumulated debris,

which got into the #8 exhaust lifter, temporarily lodged itself between the check ball & where

it's supposed to seal on the base of the plunger, causing that lifter to collapse. Then you

adjusted out the noise, all was well > the debris clears > now the lifter returns to full length >

and now the valve is hung open > 0 psi compression.

Then you cleared that up...and here we are, at the moment all is smooth & quiet, running right,

life is good.

Am I 100% sure about all of the above? Not exactly, but as Deputy Dawg would say,

"It's Possi-bull." :0)

Now to see if the engine remains quiet. Of course this entire reply has been focused on

noisy lifters due to internal issues. Fingers crossed that all 16 cam lobes & matching lifter

bases are still smooth, unworn, and remain quiet.

Given all of the above, it's a wonder these engines run for 31 minutes -- much less 31 years. (!)

Hopefully the above gave you a little more insight into all the bits you were listening to while

setting your running lash.

Safe travels --

Attachments

Last edited: