Typically the holes on the flex plate with straight edges on each side of the hole are a smaller diameter. This aids with the plate hole alignment to the TC. When installing the TC the first bolt should be at the plate hole with straight edges.The original flexplate suffering from "ovalized torque converter bolt holes allowing noise to be generated"

theory may be wrong. After sleeping on this I took a fresh look at the video screen snap that made

me wonder:

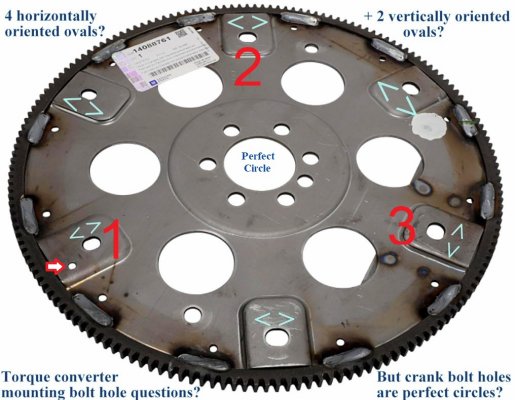

You must be registered for see images attach

I was expecting a perfect circle here, like what we see at the flexplate to crank bolt holes?

To prove/disprove the 'enlongated hole from wear' theory, I then took a close look at the

brand new GM flexplate. From here it looks like (4) of the 6 torque converter bolt holes

are manufactured horizontally oval shaped, while the remaining (2) holes are vertically oval

shaped?

You must be registered for see images attach

I'm assuming that these torque converter bolt holes are made this way in order to allow

for necessary manufacturing tolerances between the torque converter and the flexplate?

Obviously if I'm wrong then I'm hoping that a Subject Matter Expert will step in and

clarify all this?

So after giving the new flexplate close scrutiny, I'm thinking that the new flexplate

isn't going to make a dramatic difference in the quantity of noise in the vicinity?

At this point I have to step aside and let the flexplate/torque converter/transmission

gurus take the helm.

This is a tough one...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Noise from Bell housing

- Thread starter scott2093

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

If the bolts went in straight without a fight and didn’t bottom out you are probably fine. Typically if a bolt may have been over torqued you replace it to be sure. TC bolts will indeed sheer.Thank you.

I had a mobile mechanic help with the transmission last year. He may have not torqued them correctly. It was something I had discussed with him at the time. I just looked and mentioned my concerns about this in post #18. I should have put my foot down about the torque specs early on. I did bring it up but didn't fight about it. He was very good but there was obviously limited room under the truck so there was a lot going on I didn't participate in apart from the obvious handing stuff, helping move things..... I personally did the flexplate install and the oil pan and transmission pan while he was not there... no loctite or sealer was ever used last year. In fact, the sealer that was on the flexplate bolts was so bad, they had to be soaked in lacquer thinner and wire wheeled to get them looking like they even had threads. I am learning as I go so it was something I didn't even pay attention to last year and they were reused in that crazy condition.

I've already reused the 3 tc bolts although I did clean them up and applied blue loctite. I can remove them though if you really think it's needed. Still have a ways before the cover is back on. Pictures of their condition before I cleaned them with a wire wheel are in post #46.

Post #47 I mentioned with pictures of the manual section that I was a bit anxious about what the converter to flexplate torque specs were supposed to be because my manual is confusing. It says 46lbs and 50 lbs so I went with 50.

I am hoping not torquing the transmission adapter after a new seal was installed was the reason for my leak there as well..

I posted over in the transmission section about this torque converter grainy sound and a couple of other observations.If the bolts went in straight without a fight and didn’t bottom out you are probably fine. Typically if a bolt may have been over torqued you replace it to be sure. TC bolts will indeed sheer.

Any thoughts?

Noise from bell housing transmission edition

I was really hoping to avoid having to get into talking about the transmission but, I'm at the point where I guess it has a role in my search for the tapping sound coming from my bell housing area that I started another thread about. Here's where the other thread went today with transmission...

I'm assuming that these torque converter bolt holes are made this way in order to allow

for necessary manufacturing tolerances between the torque converter and the flexplate?

Yes. After removing my bolts I could see. From what I understand, the tighter clearance hole allows for torquing from the start so as to not have to turn the crank a bunch to jiggle things in line and then turn crank again to torque... Some kind of speed thing for production and ultimately repairs?Typically the holes on the flex plate with straight edges on each side of the hole are a smaller diameter. This aids with the plate hole alignment to the TC. When installing the TC the first bolt should be at the plate hole with straight edges.

At least for my truck, this is how the install is. Notice the small circle cutout on the starting pad too. No other pads line up with my flexplate so this is the way it is. Apart from getting my bearings messed up with direction of turning crank which would swap 2 & 3.....

The starting hole is very subtle in it's shape. almost like a circle....Definitely different/tighter...

thanks for pointing this out....

Attachments

Last edited:

Noise is still there albeit slight. Kinda where it was months before I started to worry enough to tear down my truck like I did this week....

Frustrating.

I'll take the cover off again in the near future and really try to find out exactly where the noise is coming from but I'm not hopeful. I tried like heck before.

I don't know if I'll go out tomorrow and the noise will be out of control again but, it's definitely not where it was before at this time.

--- Had some serious lifter tapping when I started the truck after it sitting for so long. Can't wait to address that soon.

--- Transmission case adapter to transfer case is still fn leaking..... I don't know why.... I even put some right stuff around the mating surface where I could just for good measure....

transmission fluid coming from somewhere else too. I was overfull so maybe overflow...need to find out.....

---- The s10 torque converter is nice. Pretty glad I did that. I wonder what the odds are that, since my noise is much lower now, the old torque converter was having issues and this one is flaking out right from the get go. I wasn't impressed with the condition of it. But I definitely like the feel of it. Transmission temp got to 180* after getting on the interstate and doing 80mph....Was around 140* getting around town until then.... and lingered around 160* till I got home..... Have a small external cooler.....runs through radiator first......still factory shallow pan.....

--- What's been bugging me a lot too is that my overflow reservoir for my coolant is not moving at all. My driving temps hit 200* and stay there pretty much. When the reservoir was at the hot mark after driving a couple of weeks ago. It just stayed there. Didn't move when I checked the following day cold.....

So I took some out til it was at the cool line. Hasn't moved....

It used to have activity before new water pump and thermostat. I think it does have activity or has in past since these were installed but it's been very hard to pinpoint what it is doing. Confusing. Not normal right?

Frustrating.

I'll take the cover off again in the near future and really try to find out exactly where the noise is coming from but I'm not hopeful. I tried like heck before.

I don't know if I'll go out tomorrow and the noise will be out of control again but, it's definitely not where it was before at this time.

--- Had some serious lifter tapping when I started the truck after it sitting for so long. Can't wait to address that soon.

--- Transmission case adapter to transfer case is still fn leaking..... I don't know why.... I even put some right stuff around the mating surface where I could just for good measure....

transmission fluid coming from somewhere else too. I was overfull so maybe overflow...need to find out.....

---- The s10 torque converter is nice. Pretty glad I did that. I wonder what the odds are that, since my noise is much lower now, the old torque converter was having issues and this one is flaking out right from the get go. I wasn't impressed with the condition of it. But I definitely like the feel of it. Transmission temp got to 180* after getting on the interstate and doing 80mph....Was around 140* getting around town until then.... and lingered around 160* till I got home..... Have a small external cooler.....runs through radiator first......still factory shallow pan.....

--- What's been bugging me a lot too is that my overflow reservoir for my coolant is not moving at all. My driving temps hit 200* and stay there pretty much. When the reservoir was at the hot mark after driving a couple of weeks ago. It just stayed there. Didn't move when I checked the following day cold.....

So I took some out til it was at the cool line. Hasn't moved....

It used to have activity before new water pump and thermostat. I think it does have activity or has in past since these were installed but it's been very hard to pinpoint what it is doing. Confusing. Not normal right?

xc_hide_links_from_guests_guests_error_hide_media

Last edited:

--- Had some serious lifter tapping when I started the truck after it sitting for so long. Can't wait to address that soon.

Semi-related question -- have your oil pressure readings changed with the new 15W-40 fill?

I was actually going to bring that up but wasn't sure if it was more overload of info. Was thinking about posting in other thread but, oil pressure seems similar but a few psi higher. When Idling in park it stays around 20psi when hot.... But idling in gear after tooling around town it will get around 11psi...So better than the 8 it seemed it was at before. I did notice it seems like it gets more pressure when on the throttle .... But it really was my first drive with it and it wasn't a focus of mine on this drive..Semi-related question -- have your oil pressure readings changed with the new 15W-40 fill?

But my scatter brain allowed me to notice these couple of details....

Actually also going to post something I'm curious about on the oil filter adapter thread....

You installed new thermostat and water pump.

The reason your expansion tank fluctuates is cooling system heats up , causing expansion, as pressure rises to set point cap bleeds off to tank. On cool down contraction returns to system.

If your new thermostat and water pump and coolant are operating more effectively you could be seeing less expansion therefore less cap bleed off to expansion tank.

The tank expansion is secondary to how is the water temperature operating , maintaining desired temperature? In normal conditions properly configured engine cooling system should not have much fluctuating tank level, except in high extremes.

The reason your expansion tank fluctuates is cooling system heats up , causing expansion, as pressure rises to set point cap bleeds off to tank. On cool down contraction returns to system.

If your new thermostat and water pump and coolant are operating more effectively you could be seeing less expansion therefore less cap bleed off to expansion tank.

The tank expansion is secondary to how is the water temperature operating , maintaining desired temperature? In normal conditions properly configured engine cooling system should not have much fluctuating tank level, except in high extremes.

Thanks. I expected it to be stable while 200* and idling in garage but, was surprise after a 30 minute tear through town and a 15 mile interstate run it would have shown some activity....The tank expansion is secondary to how is the water temperature operating , maintaining desired temperature? In normal conditions properly configured engine cooling system should not have much fluctuating tank level, except in high extremes.

I'll keep an eye on it... I mean temp never goes above 200* maybe 202* afaik....

I'd say the new flexplate and torque converter replacement did not fix the noise. Unless the torque converter is goofy from the start, I'm at a loss.

I can't see it being the starter. I studied my videos from before and didn't see contact anywhere......and tried the stethoscope on it .....

Guess I'll get at it again when time permits....

Kinda wondering if the latest harmonic balancer, which shakes more than the one before it, has anything to do with the noise being so prominent. But I think the noise was there before I changed balancers...

Did notice my transfer case has quite a bit of movement in rhythm with the noise too. Which is weird because the transmission is pretty still as is the motor.... I mean there is the same movement but much less. The front diff doesn't shake so it's not transmitting through the front driveshaft.....

Is there a shaft that's constantly moving in the transfer case in park?

I can't see it being the starter. I studied my videos from before and didn't see contact anywhere......and tried the stethoscope on it .....

Guess I'll get at it again when time permits....

Kinda wondering if the latest harmonic balancer, which shakes more than the one before it, has anything to do with the noise being so prominent. But I think the noise was there before I changed balancers...

Did notice my transfer case has quite a bit of movement in rhythm with the noise too. Which is weird because the transmission is pretty still as is the motor.... I mean there is the same movement but much less. The front diff doesn't shake so it's not transmitting through the front driveshaft.....

Is there a shaft that's constantly moving in the transfer case in park?

xc_hide_links_from_guests_guests_error_hide_media

Similar threads

- Replies

- 11

- Views

- 411

- Replies

- 9

- Views

- 1K

- Replies

- 1

- Views

- 176

Staff online

-

df2x44L60E Destroyer

Members online

- Nad_Yvalhosert

- bentlyw

- Morganizer

- kylenautique

- L31MaxExpress

- cwilson36

- Aaragreg

- Hills56

- 0xDEADBEEF

- Caman96

- Kurt Holzbacher

- TexQuad

- vince72

- ccobs

- msmall

- mountainmangarry

- chalupo

- Peavey

- Jimmy D

- BowhunterBrown

- mikesinclair

- 99xcss4

- 1998_K1500_Sub

- eddie1712

- Sparky95

- Supercharged111

- Connorpod

- ChrisT2006

- Mr Wes

- Clammer

- RichLo

- movietvet

- Chevyguy1282

- yevgenievich

- thewarbirdlover1

- Rainey01

- KennyBoi99

- frederik

- df2x4

- kiwiperformance

- Fwbarre

- ktrisler

- austinmcroberts

- Gasman

- dotwell69

- Astro

- drift

- 6ray18

- Loganj175

- Orpedcrow

Total: 1,378 (members: 80, guests: 1,298)