AKA - PFM!it really is pure F'n magic

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How does electronic timing advance work on a TBI distributor?

- Thread starter 95 Tahoe

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Ok , stop with the randomly poking into the obd1 port. If you accidentally send 12 volts down a 5 volt reference circuit you might get a bigger problem than now. You really need to learn or read more. Electrics is the one thing where an action taken equals a opposite and equal reaction. If your action is wrong the result can be smoke, heat, a lot of heat, then fire, then more money.

Not all OBD connectors are exactly the same, in what pins are for what function. Are you using the manual for your year truck? Not hanes or clymer junk. I wouldn't worry about getting into diagnostics or field mode. Just get it up and operating. Read this page.

Not all OBD connectors are exactly the same, in what pins are for what function. Are you using the manual for your year truck? Not hanes or clymer junk. I wouldn't worry about getting into diagnostics or field mode. Just get it up and operating. Read this page.

You must be registered for see images attach

You must be registered for see images attach

Wolvrine82

Newbie

Did you swap your prom into the new ECM and is it compatible with the new ECM?

MANIAC

Newbie

Yeah no the concern is most definitely valid but all the wires and electronics are factory the vortec engine I swapped in is from 96 to 99 originally the spider injected 350 but I bought an adapted intake plenum to make the TBI fuel system function like factory with the vortec block and headsGreetings MANIAC,

For me the engine swap changes the troubleshooting approach. To explain, if we are working on a

GMT400 that's completely factory original in the engine bay, and is suffering a malfunction, our default

mindset is to find the one component/wire/signal that is not working per specification. (Assumption is

everything is innocent until proven guilty.)

On the other hand, when we are dealing with an engine swap, a single detail difference can create a

difficult to sort out project logjam. Or worse, overlapping showstoppers hide progress, and can really

discourage the DIY'er. In other words, when troubleshooting an engine swap, the assumption needs

to be that everything is bad until proven good. (Not calling out your workmanship, just an observation

based upon helping with getting engine swaps up & running over the years.)

First things first. Let's define a couple of voltages, who makes them, and the hints that these discrete voltages mean to you.

* Approx. 12.6v-14.5v -- Battery Voltage. ~12.6v = fully charged battery, engine off. ~14.5v = engine on, alternator at goal voltage.

* 5 volts -- Regulated computer voltage used inside ECM/PCM. Also used as a reference voltage for most sensors, and also to communicate

with the scan tool via the under dash DLC. (Data Link Connector) Note: Also referred to as the ALDL or (retroactively named) OBD1 connector.

So here's a wiring diagram for the PCM (7427) equipped vehicle taken from the '95 Factory Service Manual:

You must be registered for see images attach

So when you jumper Pin A to Pin B in the underdash connector, what you are actually

doing is grounding Pin B on the connector so that we can tell the computer (via Pin A1)

to go into diagnostic mode. So according to this diagram we need to ensure that the

all-critical PCM to Engine grounds are good. If there's any flakiness with these grounds

then we may or may not be able to control the computer to communicate with your scan tool.

NOTE: Pin A to Pin B puts us into diagnostic mode. But on the PCM the serial data

is sent to Pin M via the TAN wire, and if this isn't wired to pin F9 then no joy.

Now, since we're doing an engine swap, we can't assume that Pin M is wired correctly.

Why? Well, if at some time in the past there was an ECM installed (think gas engine/5-spd manual)

then Pin 'E' on the DLC connector is what was used on one end of the ORaNge wire to Pin A8 on the computer:

You must be registered for see images attach

****

I'll stop here and give you a chance to verify that your wiring matches your computer setup.

Once we get reliable communications between your computer and your scan tool, then we

will be in a much stronger troubleshooting position.

Best of luck --

PS -- I posted these pages from the '95 FSM for Driveability, Emissions, & Wiring -- as

mentioned previously, downloading the '95 FSMs is like cheating to win -- it will be really

helpful for a project like yours.

And I know they have different camshafts but it should still allow the system to read and function enough to at least drive it and I'm becoming concerned that diagnosing this issue is beyond me because it starts and idles no problem but because the timing cannot advance i don't think its safe to drive at 0° base timing and the only things as far as sensors/modules i haven't replaced are the knock sensor and the ecm prom itself

Plus when I was trying to check voltage and ground at the adl port somehow I managed to temporarily get a different result where my fuel pump stayed running with the key on,

And the injectors wouldn't fire

And what I did to reverse that I first tried wiggling the wire harness under the dash hoping it might reveal a short to ground but that didn't work so I unhooked the battery and pulled the fuel pump relay and tested it with a 9v battery to confirm the relay is functioning and when I plugged it back in and re hooked up the battery it went back to being able to start but still not advancing timing so like I mentioned it getting confusing to me because mechanical stuff I'm good with but electrical im so weak and because im a hands on learner and i have no one to help guide me through the basics its a serious uphill battle trying to teach myself how to comprehend the electrical side of things

MANIAC

Newbie

Also on another note I looked at the diagram one of you guys sent for the obd1 port and I saw that it has one of it grounds to the engine where would that particular ground be located on the block because i feel like double checking it will at least rule out that as the cause of the problem or fix it but I'm probably just grasping at straws at this point I just know I can't afford to pay a shop to find the problem assuming they had anyone experienced enough to figure it out

Also on another note I looked at the diagram one of you guys sent for the obd1 port and I saw that it has one of it grounds to the engine where would that particular ground be located on the block because i feel like double checking it will at least rule out that as the cause of the problem or fix it but I'm probably just grasping at straws at this point I just know I can't afford to pay a shop to find the problem assuming they had anyone experienced enough to figure it out

To answer your question G108 and G109 are the primary grounds between the PCM and the engine.

Here is how it is drawn on the ground distribution wiring diagram for this circuit:

You must be registered for see images attach

('95 Electrical FSM)

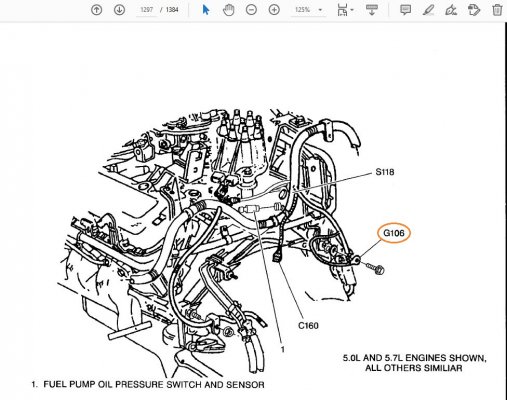

The above is the electrical wiring diagram. Below is the component location illustration:

You must be registered for see images attach

For completeness, although it's not directly part of the PCM <> Engine grounding, G106

is an important engine ground that's located on the rear of the RH cylinder head. (See attached.)

****

Please verify clean as new/tight grounds at G106, G108, & G109.

Once the grounds are verified, then in this order:

Step 1) Does the SES light come on and stay on when the key is ON and the engine is off?

Step 2) Jumpering Pin A to Pin B, do you get the flashing Code 12 plus any error codes?

(NOTE: A solid ground to Pin A14 at the computer is required to get the flashing codes.)

Step 3) Connect a scan tool and establish communication to the computer.

(NOTE: For a PCM-equipped truck, we need a good path between Pin M of the DLC connector

and pin F9 of the computer.)

****

Let us know how far you get with the steps above first. And then after we get this essential

electrical and PCM troubleshooting link established, then we can go on to worry about getting

the spark advance working. (Keep in mind that for maintenance purposes we unplug a wire in

order to open the circuit, disabling the spark advance in order to set the base timing.)

If that plug isn't firmly seated -OR- the plug is seated but that wire is broken/open along the

way, then the computer won't be allowed to advance the timing. But right at the moment the

engine's spark advance isn't the #1 priority. Instead, verify your grounds and then see if you

can get through at least Steps #1 & #2 and report back with your updated status.

Best of luck --

Attachments

MANIAC

Newbie

To answer your question G108 and G109 are the primary grounds between the PCM and the engine.

Here is how it is drawn on the ground distribution wiring diagram for this circuit:

You must be registered for see images attach

('95 Electrical FSM)

The above is the electrical wiring diagram. Below is the component location illustration:

You must be registered for see images attach

For completeness, although it's not directly part of the PCM <> Engine grounding, G106

is an important engine ground that's located on the rear of the RH cylinder head. (See attached.)

****

Please verify clean as new/tight grounds at G106, G108, & G109.

Once the grounds are verified, then in this order:

Step 1) Does the SES light come on and stay on when the key is ON and the engine is off?

Step 2) Jumpering Pin A to Pin B, do you get the flashing Code 12 plus any error codes?

(NOTE: A solid ground to Pin A14 at the computer is required to get the flashing codes.)

Step 3) Connect a scan tool and establish communication to the computer.

(NOTE: For a PCM-equipped truck, we need a good path between Pin M of the DLC connector

and pin F9 of the computer.)

****

Let us know how far you get with the steps above first. And then after we get this essential

electrical and PCM troubleshooting link established, then we can go on to worry about getting

the spark advance working. (Keep in mind that for maintenance purposes we unplug a wire in

order to open the circuit, disabling the spark advance in order to set the base timing.)

If that plug isn't firmly seated -OR- the plug is seated but that wire is broken/open along the

way, then the computer won't be allowed to advance the timing. But right at the moment the

engine's spark advance isn't the #1 priority. Instead, verify your grounds and then see if you

can get through at least Steps #1 & #2 and report back with your updated status.

Best of luck -

I will try that in a bit and let you know within a few hours and thank you for the diagram I'm definitely gonna double check my engine grounds but is pin 14 the red connector on the ECM or the blue one in not familiar with the pin outs assigned numbers yetTo answer your question G108 and G109 are the primary grounds between the PCM and the engine.

Here is how it is drawn on the ground distribution wiring diagram for this circuit:

You must be registered for see images attach

('95 Electrical FSM)

The above is the electrical wiring diagram. Below is the component location illustration:

You must be registered for see images attach

For completeness, although it's not directly part of the PCM <> Engine grounding, G106

is an important engine ground that's located on the rear of the RH cylinder head. (See attached.)

****

Please verify clean as new/tight grounds at G106, G108, & G109.

Once the grounds are verified, then in this order:

Step 1) Does the SES light come on and stay on when the key is ON and the engine is off?

Step 2) Jumpering Pin A to Pin B, do you get the flashing Code 12 plus any error codes?

(NOTE: A solid ground to Pin A14 at the computer is required to get the flashing codes.)

Step 3) Connect a scan tool and establish communication to the computer.

(NOTE: For a PCM-equipped truck, we need a good path between Pin M of the DLC connector

and pin F9 of the computer.)

****

Let us know how far you get with the steps above first. And then after we get this essential

electrical and PCM troubleshooting link established, then we can go on to worry about getting

the spark advance working. (Keep in mind that for maintenance purposes we unplug a wire in

order to open the circuit, disabling the spark advance in order to set the base timing.)

If that plug isn't firmly seated -OR- the plug is seated but that wire is broken/open along the

way, then the computer won't be allowed to advance the timing. But right at the moment the

engine's spark advance isn't the #1 priority. Instead, verify your grounds and then see if you

can get through at least Steps #1 & #2 and report back with your updated status.

Best of luck --

MANIAC

Newbie

Also check engine light does stay on with key on btw

MANIAC

Newbie

Also for the g108 and g109 grounds if my intake is pure aluminum will the grounds still be good or do I need to relocate them because they are in the correct location other than g109 that I have to move from the other thermostat housing bolt to one of the plenum bolts and no 108 and 109 are not on the same bolt but they both take up a bolt on the housing I figured I'd better specify

Also for the g108 and g109 grounds if my intake is pure aluminum will the grounds still be good or do I need to relocate them because they are in the correct location other than g109 that I have to move from the other thermostat housing bolt to one of the plenum bolts and no 108 and 109 are not on the same bolt but they both take up a bolt on the housing I figured I'd better specify

Good on you for keeping track of any/all changes that you are making from the stock configuration.

And when you have a question about a change like this that you proceed to find out how it will affect the overall

project.

In this case, good news. Although both are conductors, aluminum is actually a better conductor

than cast iron. Check out where they fall on this list of metals, organized from highest to

lowest conductivity:

You must be registered for see images attach

NOTE: All of the above is for pure, untarnished metals. Since gold is a noble metal and

remains untarnished in everyday environments, most people think that gold is the best conductor.

It may not be the most conductive, but gold is the most reliable because it doesn't end up with

corroded surfaces. And this reliability is why we see so many gold contacts used in electronics.

In English, no need to worry about that aluminum intake manifold. Just keep those grounds

connections clean like new and you should be all set.

Again, good on you for paying attention to any changes made during your engine swap.

And don't forget that if engine swapping was easy everyone would be doing it.

Last edited:

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 22

- Views

- 3K

- Replies

- 27

- Views

- 2K