A noise just started about 30 minutes ago. We came back from an evening cruise only to have it make a nasty clanking noise once we made it back to the house. Clutch in it would be quiet. Out and it would clank.

Sorry to hear that the problem is worsening. But thanks to you paying attention to when the

noise is stimulated vs when it disappears we can use this to narrow down where to expect to

find the failing part(s).

When troubleshooting a noise in a standard transmission we need to be able to move the 'speed differential'

around. That is, where the parts are rotating on one side while the other side is stationary.

Here's the different tests that we can run prior to opening everything up, essentially each step always moving the speed differential point rearwards.

(NOTE: This is a bit of an oversimplification, but it helps to understand the testing methodology & keeping track of where the noise is being generated.)

1)

Everything stationary. Used to test basic shift linkage adjustment. (Engine off, transmission internals stationary, driveshaft/wheels stationary.)

2) Engine idling, clutch

disengaged, wheels stationary. (Spinning flywheel, pressure plate, and throwout bearing, with

stationary trans input shaft & internals.)

- Used to see if pilot bearing or throwout bearing become noisy in this mode. Also to check if non fully releasing clutch is causing shifting difficulties.

3) Engine idling, clutch

engaged, transmission in neutral, wheels stationary. (

No speed difference between pilot bearing and transmission input shaft.

- Also clutch disc at same speed sandwiched in-between flywheel and pressure plate.

- However, we have now added a spinning transmission

input shaft at engine speed. IF the noise now starts up, then we need to focus on the

- stationary parts in Test #2 that are

now spinning. (Think input shaft bearing {highest probability, it leads a demanding life} or internal gear meshing.)

4) Engine running, clutch engaged, transmission in gear, rear wheels rotating. (All parts spinning, sounds may vary by

which gear that the engine

- torque is being coupled through.)

5) Advanced testing: Engine OFF, clutch engaged, transmission in neutral, driveshaft/rear wheels still rotating due to vehicle coasting down the road.

- Used to try to pinpoint if the noise is emanating from the input bearing/input shaft vs the output shaft/output bearing/out back.

It's actually not nearly as complicated when I demonstrate this in person versus typing it all in. The point I'm

trying to make is that by changing where suspect interacting parts are stationary to each other vs causing

relative movement between them and observing the presence or absence of noise, we can often tighten up

the probem description up to a specific area. (Example: Either the pilot bushing/bearing is noisy when the clutch

is depressed and there's a speed difference generated. Or the wounded throwout bearing spins up to speed and

starts squawking while our foot holds it against the spinning pressure plate.)

As opposed to the input shaft/bearing is noisy when the clutch is engaged, so the input shaft/bearing starts

spinning while the throwout bearing has come to a stop. (!)

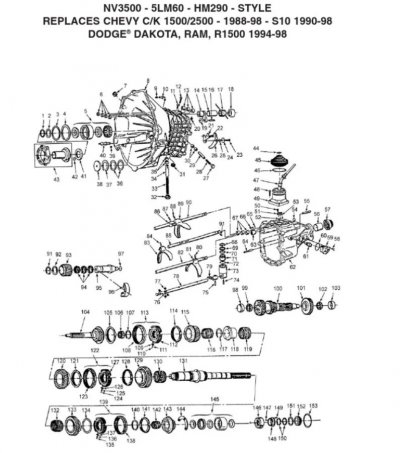

For what it's worth I've included an exploded diagram of the NV3500, which is helpful to trying to visualize

which parts are rotating when in the different operating tests described above. And as a bonus I included

a photo of a NV3500 input shaft & input bearing.

Sounds like the time has come for a teardown & inspection. Of course the input bearing could be OK, but

a shifting bit has broken off, fallen into the gears, and now announces itself as a foreign object any time

the internal gears start spinning, for this seems to be identified here and there on the few NV3500 threads

that don't dead end before the root cause is shared.

For what it's worth --