Hello JalopiedAllOver,

HotWheelsBurban is on the money with all this. There are some critical details that

we 21st century DIYers have to pay close attention to.

The length is important for proper clamping, and in the good old days everything came

together easily due to the fact that everything involved was designed/manufactured in SAE 'standard' dimensions.

However, the new PMGR starters that everyone is upgrading to are a metric design, and the holes that the 2

starter bolts go through will have excess clearance if English bolts (that thread directly into the block)

are utilized. In other words, the starter can twist or misalign unless you use the exact right

conversion bolts.

Here's a couple of threads where a good description of all this has happened:

(

Big and little starters + special metric shank/english thread bolt details)

and

(

Schurkey shares starter & conversion bolt photos & details)

****

Don't know if you have already extracted the snapped off part of that starter bolt.

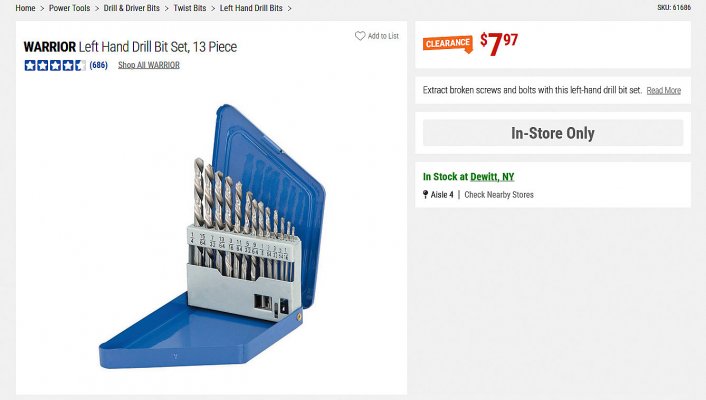

If you haven't, I've actually found these affordable left-handed drill bits at the local

Harbor Freight to work much better than their price would lead you to believe.

(See attached.)

Here in the rust belt plenty of bolts snap off despite all the normal efforts to ease

this stuff apart. Once I started using these, after stepping up in size a few times,

often the drill bit will catch, and instead of trying to send the remnant further down

the hole, when the left-handed bit spinning CCW it catches and threads it out for

you as neat as you please. (!)

I buy these kits 2 at a time, always have a fresh kit in the traveling SNAFU bag, give

them to my motorhead buddies at Christmas, etc. It's become an essential lifestyle

thing in the old car/truck hobby. :0)

As always, the trick is to to get that first hole started as close to the center of the

bolt/stud as possible. If you are lucky, within 2 or 3 drill size steps it spins out.

Other times I'm pretty close to the threads themselves before the drilling function

relaxes everything enough for it to come out. (We used to have a small 'wailing wall'

in the shop, and some of our prized items on display were snapped off bolts that

looked like heli-coils because this is how we got them out. This wall often gave us

inspiration/reassurance by showing us that removing snapped off bolts *is* possible. :0)

Hope this is helpful. Getting these starters really right & factory reliable *is* possible,

and is well worth the extra effort.

Best of luck --