Thanks for the detailed reply. The lowest value on the 02 sensor was around .4MV from watching the graph. It goes very high to very low. I haven't checked the fuel pressure yet. I plan to do this over the weekend since I will probably need to take a bath in gasoline to do this if I do it at the fuel filter location.Not real reliable.

The computer is in lean-command, trying to get the actual air-fuel mixture to the desired 14.7:1. IF the O2 sensor is showing the expected swing between low- and high-voltage, the mixture is "correct", averaging neither rich nor lean.

.4 mV and 800 mV? Or 400mV and 800mV?

400 to 800 mV would indeed be "rich". I don't think I've ever seen an O2 sensor go down as far as .4 mV, but a swing from very low to very high voltage is normal for a properly-functioning O2 sensor.

Let us know how that goes.

For the record, the "right-side injector" does not feed only the "right bank". Both injectors feed two cylinders on each bank--the two outer cylinders on one bank, the two inner cylinders on the other bank.

One injector feeds 1, 7 (outer left bank) and 4, 6 (inner right bank).

The other injector feeds 2, 8 (outer right bank) and 3, 5 (inner left bank).

Therefore, a TBI with only one O2 sensor, is still sensing the fuel output of both injectors.

Good catch on the EGR.

It's not commanding a lean condition. It's in lean-command, trying to get to a CORRECT air-fuel ratio. Lean-command is reducing the "expected" amount of fuel according to the base programming because for some reason the base programming would be too rich on your engine. For example, excessive fuel pressure. The O2 sensor (if it's working properly) is the best way to determine rich/lean, and yours seems to be showing a proper air-fuel ratio once the fuel trims are in lean-command.

What is your fuel pressure?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TBI 350 Running Rich

- Thread starter 95 Tahoe

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Just a follow up if anyone has the same problems. I've read a ton of these threads recently and they all fizzle out without a conclusion. The EGR solenoid cleaned up most the problems that I thought was coming from running rich. I don't have the soot accumulating on the exhaust now.

That's great. Were your fuel trims back to normal?Just a follow up if anyone has the same problems. I've read a ton of these threads recently and they all fizzle out without a conclusion. The EGR solenoid cleaned up most the problems that I thought was coming from running rich. I don't have the soot accumulating on the exhaust now.

Just a follow up if anyone has the same problems. I've read a ton of these threads recently and they all fizzle out without a conclusion. The EGR solenoid cleaned up most the problems that I thought was coming from running rich.

Sir,

Would you be willing to try driving a day or 2 in TBI's Field Service mode? This way, instead

of guessing, you can see if you are running too rich / too lean / stoich simply by watching the

SES light flash easily discernable patterns. (See attached.)

This is a neat little-known built-in diagnostic that you gain access to by jumpering Pin A to

Pin B in the ALDL connector while the engine is running. (See attached.) I've been trying to

get TBI drivers to use this and report back to the community, but so far there have been

few takers.

****

BTW, thank you for coming back & closing the loop by reporting your long-term results.

Wish more folks would do this, for a long thread that fizzles out is not that helpful.

Attachments

Last edited:

I'd do it.....This is a neat little-known built-in diagnostic problem that you gain access to by jumpering

Pin A to Pin B in the ALDL connector while the engine is running. (See attached.) I've been

trying to get TBI drivers to use this and report back to the community, but so far there have

been few takers.

But is my 110 BLM pretty much saying the same thing? This trick is in lieu of a scanner?

I'd do it.....

But is my 110 BLM pretty much saying the same thing? This trick is in lieu of a scanner?

If you go over to this REPLY you will see a link to a short video that another TBI forum member posted.

And if you look at the attached on the bottom you will see a graph I made showing what mode the ECM

was in at what point in time on the video.

Basically he has asking if the SES light was supposed to flash like this. (He had connected Pin A to Pin B

on the ALDL so that he could retrieve the Key On Engine Off codes, but afterwards started the vehicle and

this was going on.)

****

It would be interesting if you could get the Field Service Mode to confirm your 110 BLM. My understanding is

that 128 is perfect, no change needed from the factory tables. There are a total of 16 memory locations which

the computer climbs like stairs as we go from no load idle to full throttle grade climbing. Each memory location

will have the BLM value in it for the power range that this memory location is responsible for.

And this stored value is the fuel trim that the computer has figured out over time (using the O2 sensor feedback) in

order to fine-tune the fuel delivery for *this* vehicle's specific combo of injector flow x how many PSI of fuel that this

regulator was delivering, and also the misc. drift of everything else involved in Closed Loop operation.

So if you looked in the cells and they were all greater than 128, this means that the computer is adding some extra

percentage of fuel to whatever the factory calibration is stored in the tables.

Conversely, numbers below 128 mean that the computer is trimming some percentage of fuel off of

the factory calibration stored in the tables.

In English, there isn't a single overall BLM (Block Learn Mode) that covers all engine operation. According

to the FSM there are 16 locations, from a no load idle to WOT at max rpm. Getting back to the Field

Service Mode, if your trims are all dialed in, then I would expect the O2 sensors to give you a slow flashing

SES light (Closed Loop) with a 50% duty cycle. (Stoich, not too rich or too lean)

Here's a quick made up scenario. During light throttle and light loads, the SES light is flashing to indicate

a lean condition, but when you get on the highway & cruise at 70 mph, *now* the SES light is flashing

to indicate a correct (stoich) A/F ratio. So the question becomes, "Why is the fueling lean during light

loads but is good at moderate load cruise?"

A: At high vacuum & light load, there is a vacuum leak due to a failing intake manifold gasket that's causing

additional fueling to be required overcome the issue. But the leak has gotten bad enough that the local trims

have pegged. Meanwhile, the O2 sensors only report what they are currently sniffing in the exhaust stream.

Meanwhile, on the highway at 70 mph there is less vacuum (and more throttle opening) and the

manifold leak has less effect on the fuel delivery. (The heavier load is masking the leak.)

So if the SES light is a 50% duty cycle on the highway, but also flashing to show a too lean condition

at light load/small throttle opening, then this can give us a clue about what's going on.

How about one more failure scenario? Let's say that around town at legal speeds all is Closed Loop stoich.

But when accelerating up the onramp or climbing a grade the SES is flashing a Too Lean pattern. But if

you let off some the engine goes right back to stoich. But you depress the throttle again and the Too Lean

pattern shows *again*. If you have a fuel pressure gauge connected you also happen to see the fuel pressure

drop off every time you give it the heavy throttle.

The inline fuel filter looks to be an old soldier, so you replace it with a new one, and Voila! Now when you heavy

throttle/climb that same grade your vehicle stays in a 50% duty cycle SES flash denoting proper (stoich)

operation is maintained.

NOTE: The TBI system is designed to go Open Loop on purpose (rapid flashing) when at/near full throttle operation

is demanded by the driver. So don't confuse this with the partially-clogged fuel filter scenario above.

****

In English, once you get the hang of Field Service Mode, you will be able to figure out not only when the

Closed Loop is working properly, but also when it isn't. You having a '110 BLM' tells me that for some

reason the computer is trying to lean out your system in order to get the reported A/F ratios correct.

But with the SES flashing light show you can tell me all the times that it's good vs bad:

* Lean, but only during larger throttle openings. (Fuel delivery restriction pre-regulator?)

* Rich, but only during smaller throttle openings. (Minor Dribbly TBI nozzle = uncontrolled fuel delivery)

* Rich all the time (FPR setting always too high?)

* Lean all the time (PO swapped in a 350, but left the original 305 TBI computer in place?

****

FWIW I've attached a couple of pages out of a TBI FSM for Emissions, Driveability, & Diagnosis.

Read the marked up areas and make sure I described all the stuff accurately. And follow the link

above to the other reply and watch the video. And then if you feel like it, jumper pins A&B together

on your vehicle and see if you can glean anything.

But don't drive distracted. No A/F hero to fender bender zero moments. :0)

Here's to Efficient yet Safe travels --

Attachments

Last edited:

Yes. Watching the blinky-light is what is needed if no scan tool is available.I'd do it.....

But is my 110 BLM pretty much saying the same thing? This trick is in lieu of a scanner?

If you have a scan tool, you're way better off than having to decipher the blinky-light flashing speed and on vs. off time.

You're looking for Block Learn and Integrator (long-term and short-term) fuel trim corrections, with the emphasis on the long-term more than short-term.

Yes. Watching the blinky-light is what is needed if no scan tool is available.

If you have a scan tool, you're way better off than having to decipher the blinky-light flashing speed and on vs. off time.

You're looking for Block Learn and Integrator (long-term and short-term) fuel trim corrections, with the emphasis on the long-term more than short-term.

I'm in complete agreement that a live data scan tool is preferable to a blinky SES light show.

Truth be told I'm hoping that by getting interested owners to start thinking about Open Loop

vs Closed Loop, reading plugs, and observing a blinking SES light (and maybe fixing a driveability

issue here or there) ...that this in turn will build a desire in them to eventually acquire a real scan

tool down the road. (Live data / graphing live data, Mode $06 capability, data recording, etc)

Personally I'm finding that looking at fuel trims in addition to O2 sensor activity gives a much

better picture of who's zoomin' who under the hood.

****

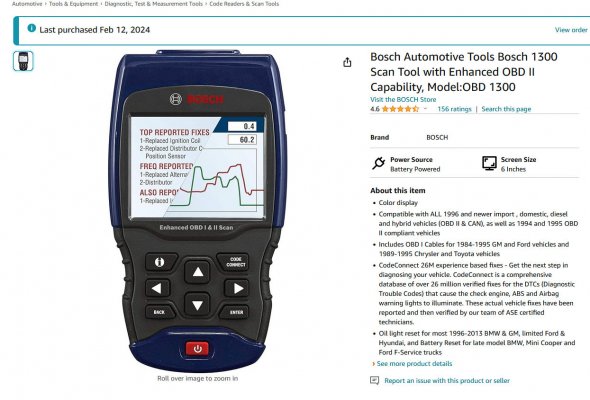

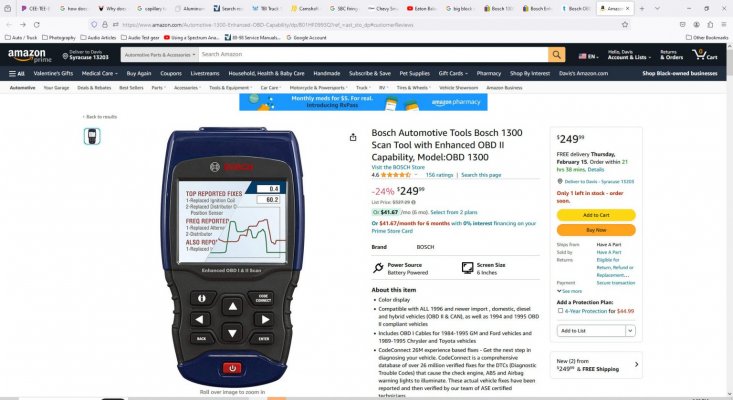

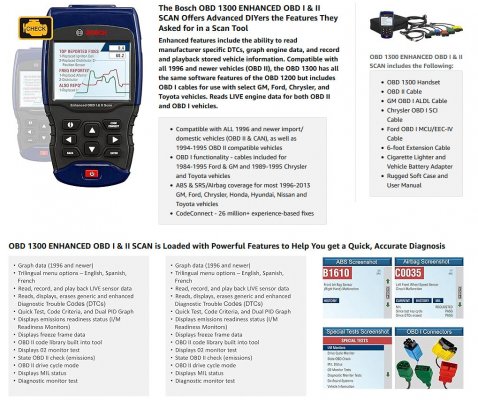

Speaking of which, after reading feedback from another member plus a lot of research, a while ago

I dipped my toe in the affordable end of a 'graphing' Scan tool that included a bunch of ODB-1 connectors

in addition to the normal OBD-2 one -- the Bosch 1300.

If you look through the 3rd attachment you can see that the 1300 is the only model listed with

OBD-1 capability. And the 4th attachment shows the OBD-1 connectors that were included with

the unit.

So far I'm happy with the purchase. Of course in the fine print the 'graphing' capability is only

for the '96+ vehicles, which was a bit of a disappointment, but I ordered it anyway. (It had the

'last one' notice.) My primary justification is to use this on some non-GMT400 OBD-1 vehicles

in the friends & family category, but so far the live data seems to work just fine.

My plans are to also get a full strength scan tool with much finer graphing capability. And if I can

find a previously enjoyed auto scope in excellent condition for the right price I'd jump on that

as well.

****

Just wanted to show the TBI community that if you want a dedicated non-phone-app based scan

tool for your older OBD-1 system it looks like the Bosch 1300 is one possibility.

For what it's worth --

Attachments

-

Purchased 12Feb2024 screen - Bosch Automotive Tools Bosch 1300 Scan Tool with Enhanced OBD II...jpg243.2 KB · Views: 9

Purchased 12Feb2024 screen - Bosch Automotive Tools Bosch 1300 Scan Tool with Enhanced OBD II...jpg243.2 KB · Views: 9 -

Last 1 screen - Bosch Automotive Tools Bosch 1300 Scan Tool with Enhanced OBD II Capability, M...jpg198.6 KB · Views: 9

Last 1 screen - Bosch Automotive Tools Bosch 1300 Scan Tool with Enhanced OBD II Capability, M...jpg198.6 KB · Views: 9 -

Bosch Automotive Tools Bosch 1300 Scan Tool with Enhanced OBD I & OBD II Capability (arrow).jpg324.6 KB · Views: 8

Bosch Automotive Tools Bosch 1300 Scan Tool with Enhanced OBD I & OBD II Capability (arrow).jpg324.6 KB · Views: 8 -

Bosch Automotive Tools Bosch 1300 Scan Tool with Enhanced OBD II Capability, ModelOBD 1300.jpg289.1 KB · Views: 8

Bosch Automotive Tools Bosch 1300 Scan Tool with Enhanced OBD II Capability, ModelOBD 1300.jpg289.1 KB · Views: 8

Last edited:

That's one of the reasons I've been trying to get my aldl droid app working again. It's easy enough to see, at least with aldl droid, my phone while driving , even easier to see on a tablet. I haven't gotten tunerpro hooked up yet but anyway, screen recording the aldl droid data stream with microphone enabled allows me to take verbal notes as well so I can have an idea of what I'm doing like, "I'm getting on the on ramp and accelerating, I'm idling at a light...etc...Of course engine rpm and speed on the recording should coincide with this... My scan tool has recording too but I haven't used it yet.But don't drive distracted. No A/F hero to fender bender zero moments. :0)

I just use one of those cup phone knockoffs as a stand for my phone or tablet...

I'll try to get a good and safe setup going to record the ses light as well. That would make an interesting video to see them all play together. Wonder how to do that picture in picture stuff.....

Pretty sure I can at least do a video of gauges and ses light and it'll have my verbal cues...

One question.....

When I was troubleshooting earlier, replacing fuel filter, etc... I had the battery disconnected.

When finished and taking a drive afterwords, my blm seemed to be normal for a while...

Pretty sure my integer stays consistently around 128.....

Does resetting the computer erase all the fuel trim memories?

Last edited:

Does resetting the computer erase all the fuel trim memories?

That's exactly what happens. And knowing this will aid in regaining control under the hood.

For example, let's say that you had an aged O2 sensor that had drifted way off from it's

original calibration, making a mess out of your local Block Learn memory locations. IF you

just replaced the O2 sensor without disturbing the battery connection, you would see

the BLM values that were compensating for the old O2 sensor inaccuracy returning

slowly towards the factory tables via the 'integrator' function. (Original GM term, now

called 'short term fuel trim' once all car companies adopted the same terms as part of

the government-mandated OBD-2 standards.) Over a period of time the computer will

end up in a good place, but it will be a gradual process.

On the other hand, let's say that you changed the same O2 sensor, but also wanted the

computer to start off with a clean slate. After changing the sensor, you then disconnect

the battery for 30 seconds. (Per the FSM) This wipes the computer memory locations

in the volatile (ie: needs constant power to remember) memory locations.

After 30 seconds, simply reconnect the battery, start the vehicle, and (once the O2

sensor heats up) the integrator resumes making small corrections, but this time starting

from the factory values.

And IF the slight corrections (short term fuel trims) are stable, and persist long enough,

the computer will once again increment the corresponding BLM memory location in whatever

direction that improves upon the factory values, so that (as long as the battery isn't

disconnected again) this local optimization is immediately available down the road.

This is part of the strategy to keep the emissions as low as possible on a per-vehicle basis,

while also delivering that 'just been given a sharp tune' feel to the driver. (There's actually

a term used to describe this area of engine performance - customer 'Pleaseability'.)

I'll try to get a good and safe setup going to record the ses light as well. That would make an interesting video to see them all play together. Wonder how to do that picture in picture stuff.....

Pretty sure I can at least do a video of gauges and ses light and it'll have my verbal cues...

Personally I think that this would be a valuable training aid to a DIY'er that's new to the old truck hobby.

Because failure analysis is in danger of becoming a lost art. And even back when the TBI GMT400s were

coming off the assembly line back in the '88-'95 timeframe, this was pretty much pure voodoo to the

guys who were used to adjusting the idle screws while watching a vacuum gauge and also using a timing light.

The Maintainability engineers realized that this new-fangled feedback loop technology could easily cause a

tangled up troubleshooting mess out in the field, where a problem with the feedback loop itself could easily

lead the dealer mechanic to swap out nearly everything on the engine, and still end up with the same customer

complaint remaining? (They had yet to create the phrase 'parts cannon'; this came later. :0)

Fast forward ~30 years, and now you can watch troubleshooters on YouTube using these highly capable

Pico oscilloscopes to instrument a car like only the largest automaker labs could do back in the day. So

instead of a million dollar calibration lab you can now have the same diagnostic power in your hands for

only $10K or so. An amazing improvement, but if you are like me I don't have a spare $10K burning a

hole in my pocket at the moment. :0)

But if I set the wayback machine to 1993, and arm myself with a good vacuum gauge, fuel pressure gauge,

timing light, all the factory service manuals with the diagnostic charts, and take advantage of the Field

Service Mode, I will enjoy the same success rate as the old regional reps that used to help the

dealership mechanics with the occasional really tough 'unfixable' new vehicle. Especially if you can score a

working vintage scan tool that matches what you are shown in the FSM.

****

So I think your video idea is great. Watching how all this theory operates while you are driving around

in the real world will take so much of the mystery out of all this. And the way that you test your own

troubleshooting knowledge is to make a prediction of how the system is going to react to a change, do it,

and was your prediction correct?

If your prediction was wrong, then you have yet to gain control over the situation. On the other hand, once

your predictions start coming true (OK, I'm coming up to the intersection, and the SES light will start flashing

rapidly because the unheated single-wire O2 sensor is going to cool off enough** that the engine bay will go

Open Loop until I take off again) ...the more that you will be in control of the situation.

FWIW, I used to use this method while working on aircraft avionics. I used to explain that we are going

to fix this problem, but not until we can first predict with accuracy when the subsystem will and and

will not work as advertised. (That was the hard part -- the easy part was actually replacing the bad

black box or repairing the bad signal wire.)

The bottom line is that you eventually want to up your game over time incrementally. All this effort

wouldn't be necessary if every time the engine ran wrong that an intuitive Code would spring up &

guide you directly to the final fix.

* But in the real world the codes won't clear, ever after many parts are replaced.

* Or the system never kicks a code (since the emissions increase remains under a threshold) but the vehicle stumbles, won't take the gas, etc.

But to go from following the computer codes blindly to analyzing the live data, Schurkey-style, and

fixing the issue way before a code is ever kicked is the goal. But just like anything good, it's a

journey. Start with codes, add the blinky lights for free, use this to learn the underlying theory of

operation, and if you are still interested in pursuing this skillset, invest in a live data scan tool,

whether it's a period-correct Snap-On brick, dealership Tech 1 or Tech 2 tool, or something more

modern that can still reach all the way back to OBD-1 land.

And I think that your proposed video could really help others who are trying to become more in charge

of their GMT400 destiny, instead of sitting in the waiting room and hoping that *this time* the

mechanic will be able to figure out what's wrong with why the machine has become an unreliable

traveling companion.

And if you do this long enough, you will end up able to truly appreciate @PlayingWithTBI's

and @L31MaxExpress's posts on this subject. And from over here it looks like they are having a

lot of fun making these vehicles run a lot better than they have any right to. :0)

Apologies for the length. But your video idea is pretty cool. And I happen the think that the depth

of engineering in the TBI system (especially in the area of ongoing Maintainability) is superior to a lot of

more modern aftermarket setups. Similar to how an old tube amp can deliver the same/better

tone as a brand new box on the Best Buy shelf. Just because something is old doesn't mean

that it is obsolete, and that newer is always necessarily better. Depends a lot upon how much Pleaseability

was engineered in the design. :0)

Food for thought --

EDIT: **According to the guys that are elbows deep in this stuff, some of the early calibrations would

ignore the O2 sensors at/near a full stop? Supposedly the engineers didn't want the engine idle quality to

suffer as the unheated single-wire O2 sensors were cooling off while sitting at a stop light? This calibration

would explain why upgrading to a 3-wire heated O2 sensor will cause most, but not all, of these older vehicles

to change their behavior in this area.

Last edited:

Similar threads

- Replies

- 1

- Views

- 220

- Replies

- 12

- Views

- 6K

- Replies

- 69

- Views

- 8K

Staff online

-

df2x44L60E Destroyer