There's another topic that no one has touched on yet and that is ring tension. When an engine gets really hot the heat will anneal the compression rings. Many times I've seen guys cook their motors then put a new or rebuilt set of heads on it only to have serious blow by when they put it back together. I did it once myself when I was young and dumb. If you're mechanically inclined rebuild it yourself,if not buy a new crate motor. Salvage yard engines are a crap shoot!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine advice—How screwed am I (pics)

- Thread starter mayvillain

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Geese Shurk! How far did you drive that thing with a blown head gasket? I don't recall ever seeing one burnt out that bad.IF in fact you've had a head-gasket failure between two cylinders, beware block or head erosion from the blowtorch effect of combustion gasses pushing from one cylinder to the other.

My 18-year-old Caprice crate-engine installed in my '88 K1500.

The block MIGHT be salvageable, the head is gouged so deeply that there's no hope.

You must be registered for see images attach

You must be registered for see images attach

MAYBE 15 miles.Geese Shurk! How far did you drive that thing with a blown head gasket? I don't recall ever seeing one burnt out that bad.

I had a guy try to sell me a 427 tall-deck "truck' engine where the block was blowtorched a quarter-inch or more.

Is the debris hard metal, or soft gasket material? If it's hard metal, you'll at least need new pistons and the bottom end gets redone.

If it got really hot, you really want to pull the bottom end apart and have the block magnafluxed. If you get it all back together and the block is cracked, you spent all that time and money for nothing.

If you can replace the head gaskets, you can rebuild the motor. When it comes to machine work, there's things you need to spend money on, and things you can spend money on.

Needs:

1) Absolutely have the block and heads vatted, magnafluxed, and inspected. The machine shop will tell you if anything is dorked - but be sure and ask.

2) Since your head gasket blew between cylinders, I'd have it decked the minimum amount - ask your machinist how much he had to take off to clean it up.

3) Have them install the new cam bearings - they'll have to pull the old ones to vat it.

Cans:

1) An align hone adds money, and this isn't a race motor. I can hone the cylinders myself at home.

2) Boring the cylinders adds $$. You have to replace your pistons to match, and the machine shop will have to recondition your rods and install the new pistons.

3) Head porting. You can buy SBC performance heads cheap. A light cleanup porting job is worth doing yourself, but paying a shop isn't economical.

Also, it's absolutely worth it to upgrade to a roller cam. Hopefully your block already has roller cam provisions. Get all the bits from a junkyard L31 and it becomes a cheap upgrade.

If it got really hot, you really want to pull the bottom end apart and have the block magnafluxed. If you get it all back together and the block is cracked, you spent all that time and money for nothing.

If you can replace the head gaskets, you can rebuild the motor. When it comes to machine work, there's things you need to spend money on, and things you can spend money on.

Needs:

1) Absolutely have the block and heads vatted, magnafluxed, and inspected. The machine shop will tell you if anything is dorked - but be sure and ask.

2) Since your head gasket blew between cylinders, I'd have it decked the minimum amount - ask your machinist how much he had to take off to clean it up.

3) Have them install the new cam bearings - they'll have to pull the old ones to vat it.

Cans:

1) An align hone adds money, and this isn't a race motor. I can hone the cylinders myself at home.

2) Boring the cylinders adds $$. You have to replace your pistons to match, and the machine shop will have to recondition your rods and install the new pistons.

3) Head porting. You can buy SBC performance heads cheap. A light cleanup porting job is worth doing yourself, but paying a shop isn't economical.

Also, it's absolutely worth it to upgrade to a roller cam. Hopefully your block already has roller cam provisions. Get all the bits from a junkyard L31 and it becomes a cheap upgrade.

RShrimp

OBS Enthusiast

You can buy a reman long block for as little as 2K with a warranty. (just looked it up at Autozone) You could pay a shop to install and still be under 5K including a new radiator and water pump.

mayvillain

Newbie

Thank you so much for the reply! I'm overwhelmed with the support in this community, but I want to follow up with your response as this sounds like my situation.Hello mayvillain,

Everything you've shown matches up to what I would expect to see when the

head gasket fails between the 2 middle cylinders. I've marked up your photo

a bit to show where the head gasket failed:

You must be registered for see images attach

IF the engine was in otherwise good condition prior to the head gasket failure (quiet, smooth running, low oil consumption, etc)

then as long as the block surface wasn't eroded between the adjacent cylinders then a set of new/reconditioned heads & fresh

gaskets should get you back on the road. Note: The tops of the pistons should clean up no problem. (This would be the

good engine that got overheated scenario.) And if the cooling system is tired then it should be brought back to new functionality

to help prevent this from reoccurring.

On the other hand, if the engine was already noisy, low oil pressure at hot idle, already rough running, etc, prior to the overheat,

then putting a fresh set of heads atop that kind of mess is just kicking the can down the road. And a rebuilt engine is

the smartest answer.

But that's a decision only you can make. The bottom line is that the way the head gasket failed between

the inner 2 cylinders matches the classic SBC way. Certainly fixable, depending upon the decision criteria above.

Best of luck --

After closer inspection, both head gaskets are blown out in the exact spots you indicated. After reading this, my goal is to continue with my cylinder head job (I am also replacing the radiator, water pump, and timing chain).

A few other things I wanted to respond to in the "Was it a smooth running truck?" line of questions:

1. Oil pressure: I think the gauge was broke when I bought the truck ~2 years ago; it just kinda fluctuates all crazy, off the charts, etc. I will fix that.

2. Oil burning: About 1 quart every 3,000 miles.

3. Overheating: About 5 months ago, my idler tension pulley burnt out on the freeway, kicked the serpentine belt off, and my truck overheated. I replaced all the parts, but I'm wondering if this was the start of my problem...

4. Smooth operation: The truck runs great overall, the ONLY thing I can think of is that at very low RPM (like coasting through a parking lot on cold start) sometimes the truck will 'lug' or 'lurch', almost like you're about to stall a manual transmission (the truck is auto). It's noticeable because it will jolt you a little bit.

I do agree an engine replacement is optimal, however spending $1k to have a truck that runs around town vs $5k+ for a new motor is a better scenario for me at the moment (just had our first kid, literally yesterday).

Thank you again for the advice. I will vacuum out all the gasket debris in the cylinders, examine the cylinder walls, clean the pistons (not sure with what yet), and proceed with my cylinder head project (valves, etc.)

mayvillain

Newbie

Thank you, this is excellent advice. Upon closer inspection, it's definitely gasket material on top of the piston; the piston metal itself is not pitted.Welcome to the forum from Oregon.

When you say you got the engine "red hot", what are you referring to? The temp gauge reading....what?

If it got hot enough, that debris could be pieces of head gasket that broke off because of how hot and then melted to the piston edge.

IMO, from what I see, it means an entire engine tear down, to look at everything and check line bore, which any reputable machine shop would do anyway. If you have the time and want to keep that engine with the truck, hope that there are rebuildable heads with no cracks and hope the block is the same way. If you are doing all the r&r labor, then your $5k budget is doable. If can, get an experienced friend to help and feed him/her food and beer. Yanking an engine out is really not that bad on these trucks, if you have the right equipment. You say your budget is $5k. Find another $1k to $2k for a cushion and plan on replacing some other items/components along the way. A new torque converter and all mounts and transmission and transfer case services....etc. I would inspect the truck, stem to stern, to see if is worth keeping.

For instance, I am in the process of buying a GMT800 K2500 pickup. When I do this, I am either selling my 2005 Tahoe Z71 or giving it to my girl and selling my girl's 1990 K2500 extended cab, 130k miles 4x4 truck with 130k miles on it. I have a garage thread about it here at this forum. I also just put a new Retro Radio in it.

Good luck.

I'm hoping to proceed with my cylinder head project and get a few more years out of the truck before an engine replacement. I know this isn't optimal but it's what I can afford at the moment.

mayvillain

Newbie

Excellent advice, and thank you for the reference pictures. My gaskets didn't blow apart quite that bad, but I will inspect the block/heads for where they did fail and see how bad it is.IF in fact you've had a head-gasket failure between two cylinders, beware block or head erosion from the blowtorch effect of combustion gasses pushing from one cylinder to the other.

My 18-year-old Caprice crate-engine installed in my '88 K1500.

The block MIGHT be salvageable, the head is gouged so deeply that there's no hope.

You must be registered for see images attach

You must be registered for see images attach

2. Oil burning: About 1 quart every 3,000 miles.

To me that's a positive indicator. Many times someone will want to put a fresh set of

heads on an engine that's burning a quart every 500 miles, and unless it's a clear case

that only the valve stem seals are the root cause of the excess oil consumption then I

usually tell them not to do it.

Especially if the oil burning is combined with low oil pressure at a hot idle. Even more

so if the engine sounds like a diesel on a cold start due to piston slap.

3. Overheating: About 5 months ago, my idler tension pulley burnt out on the freeway, kicked the serpentine belt off, and my truck overheated. I replaced all the parts, but I'm wondering if this was the start of my problem...

I think so. In the bathtub curve of the service life of a SBC, you can accumulate a lot

of miles on one of these (even though all the gaskets/mating surfaces are no longer in

brand new unworn condition) ...IF it never overheated. A good overheat can easily stress

a vintage head gasket to failure. But IF the overheat is promptly corrected, oftentimes

the overstressed head gaskets will wait to fail until a few more miles have accumulated.

And I think that this is where you currently are. As the talent in here will tell you, be

extremely suspicious of any potential heat-related cracking in those heads. Meanwhile,

I've seen a lot of blocks soldier on after a overheat w/no real problems, especially if it

was a 1-time event like your serpentine belt failure would cause. To understand why this is,

all you have to do is visualize where all the combustion heat is concentrated. (Exhaust

valves, combustion chambers, and piston tops vs everywhere else.) IF you use a

really savvy machine shop that has worked hundreds of sets of SBC heads they will

be able to guide you as to whether your heads are good candidates for a rebuild, or

if a new set of heads is a better long-term investment.

4. Smooth operation: The truck runs great overall, the ONLY thing I can think of is that at very low RPM (like coasting through a parking lot on cold start) sometimes the truck will 'lug' or 'lurch', almost like you're about to stall a manual transmission (the truck is auto). It's noticeable because it will jolt you a little bit.

I do agree an engine replacement is optimal, however spending $1k to have a truck that runs around town vs $5k+ for a new motor is a better scenario for me at the moment (just had our first kid, literally yesterday).

CONGRATULATIONS! Becoming a dad is by far the best gig I've ever had. So good that even engine building

became a way to save money (in order to do right by my daughters) as opposed to being the ultimate

destination, if you know what I mean. (I'm the guy who would rather work on something cool on

the engine stand rather than be stuck on a cruise ship power noshing...with no engine building books

to pleasure read. :0)

And since you aren't running your business off of this truck while it's constantly loaded to the max GVWR,

if you can take a large, good flat file across the engine block surface and get everything to clean up to the same

overall color (especially between the center cylinders) then I think that you will be able to put a good-enough

long-term fix on this engine to cover your 'runs around town' needs.

Thank you again for the advice. I will vacuum out all the gasket debris in the cylinders, examine the cylinder walls, clean the pistons (not sure with what yet), and proceed with my cylinder head project (valves, etc.)

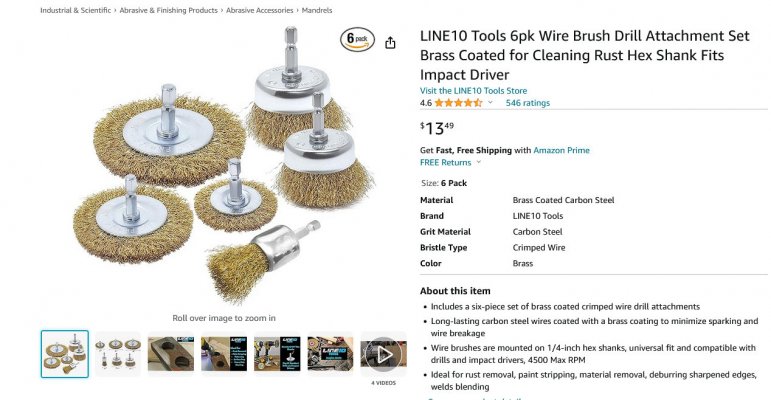

I think an affordable set of brass brushes that you can put on your drill (see attached) will give

the ability to clean up the piston tops without causing any damage. Just bring each piston pair

up to TDC and take your time. Use a little solvent if needed, but otherwise these will give you the

kind of results pics that you would want to share with us. :0)

And a large, fresh file may seem like a luxury, but that's how all us shade tree mechanics were able

to visually prove to ourselves that we caught the head gasket failure in time before the block deck

was permanently damaged.

Best of luck. And again congratulations on your newborn. Way cool.

Attachments

Last edited:

Similar threads

Staff online

-

df2x44L60E Destroyer

-

kennythewelderOfficially Retired, B31-3 (6-G) certified welder.

Members online

- Bow_61509

- BlackOnyx

- Cadillacmak

- KY-N

- SAATR

- 62barsoom

- Natewoody881

- bretcopsey

- zacharyhillary

- NCchris

- chalupo

- jvick9494

- Orpedcrow

- trulythechad

- JoeHorton

- Charlesteneows

- Minn95Dually

- 90reddu411y

- Supercharged111

- 99xcss4

- Red Devil

- 1998_K1500_Sub

- nowukno

- plumbtuf

- offroadtahoe

- Sean Buick 76

- I2312321

- MikeHT95obs

- df2x4

- squirrels2k

- Doppleganger

- Jrogosich

- Drunkcanuk

- L31MaxExpress

- justjewhat42

- Shthfkup

- JohnZ71

- El Tigre

- Silvax11

- JPVortex

- Fragment

- SethGrove0

- isomswim

- caw_86

- kennythewelder

- Grif54

- Caman96

- MatP

- JDGMC

- GrimsterGMC

Total: 2,718 (members: 88, guests: 2,630)