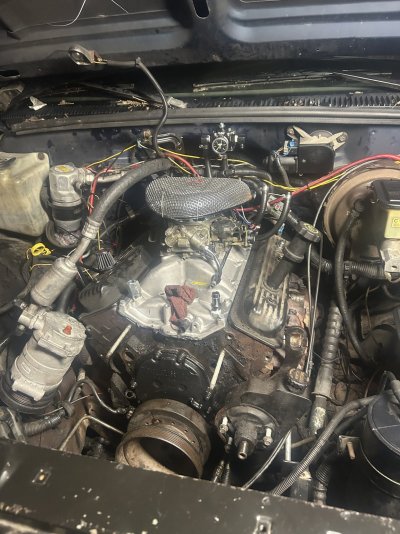

It’s an hei distributor with a vacuum advance

Oh okay sorry, back on track then my bad. So with the vacuum advance hose disconnected most Chevy small blocks are happy at about 32-36 degrees of total timing. You have your initial timing setting which it will sit at when idling. Then once you rev the engine the mechanical advance will kick in and raise the timing. Unless you use a dial back timing light it’s tough to determine the total timing. Basically you rev the engine while using the light to check the timing. Once the timing stops rising up that’s the limit of the mechanical advance. The reason it’s important to check to see how many degrees of mechanical advance are added is so that you don’t go beyond the 32-36 max setting.

So let’s just say you have 20 degrees of mechanical timing in your distributor you can safely set the initial timing at 12 degrees and possibly as high as 16 depending on the particular engine.

Once you get to this point you can test drive it and dial in the timing a bit more as needed. Listen carefully for any pinging noises from the engine especially up hills at full throttle. If you hear any ping then back off the timing 1-2 degrees until you get no ping.

Next you can add the vacuum advance to the mix. I prefer a ported vacuum source but you can try a manifold vacuum source. Again if you get ping then look into limiting the travel of the vacuum advance canister using a tack weld or a tiny nut and bolt. Crane cams sells a kit that comes with different stiffness springs to adjust how quick the mechanical advance comes in along with a vacuum canister that you can adjust the sensitivity using an Allen key.

Some distributors have an extreme amount of mechanical advance while others have less so that’s why you need to check to see how much your is actually advancing. Mr gasket sells a bushing kit to reduce the amount of mechanical as well.

I know it sounds tedious but taking the time to dial this in will really help get it running 100%!

The first step would be setting the valves.