Zimmerly

OBS Enthusiast

Hey guys.

98 K1500 ext cab, 5.7 Vortec.

Background of myself, I own a truck identical to it that I rebuilt a lot of. No schooling, self-educated mechanic with fairly good knowledge of the GMT400.

Now on to the truck... I just bought it a week ago. It runs a rough idle, smells rich, and has noticeable misfires. Looking around, I notice a new nylon main fuel line from the tank to the engine bay. The tubes going into the injectors look newer as well. I can tell the evap tubes have been messed with, because the upper one isn't routed the way it should be around the upper rad hose. The lower tube looks to have been replaced. Looking back on the driver side frame rail, I notice the fuel vent tube has been cut out, from the drivers door to about 1ft before it becomes rubber near the tank, so there is no vapor going into the evap canister. I have a feeling this isn't my main issue, but then again I'm not a pro. The previous owner said he just installed a new cap and rotor, and I know he did (or at least someone did), because it's black, while the rest of the distributor is still the stock gray color. He said he [thinks] it needs a new ignition coil. I've already replaced the PCV valve because it was rattling while running, and I thought there was a long shot that might've been what I needed, but of course not.

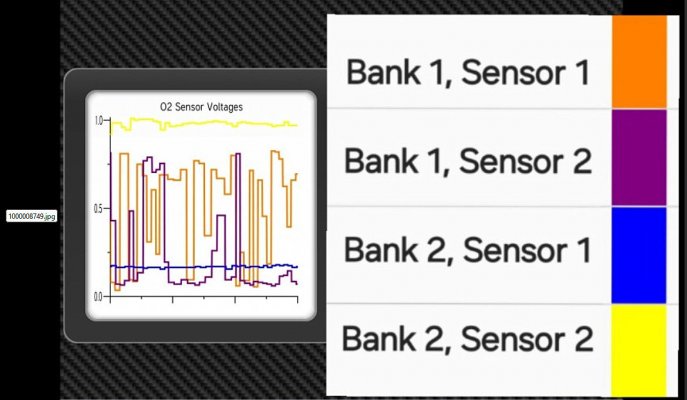

I used my Bluetooth scanner with Dashcommand, and found lots of misfires. A little on bank one, but a LOT on all of my even numbered cylinders, which I found interesting.

Since my other truck and engine are identical in model and year, I plan on swapping coil units to see if that's the case, but I'm having my doubts. I don't want to just throw parts at it based on personal "hunches", so I came here for help. I've turned to this forum so many times, and to be honest, I would not have been able to complete a LOT of projects on my build, if it wasn't for this great community. Anyway, enough of the sappy crap.

I just don't know where to start. I do know it's getting too much air and not enough fuel. I checked all air connections and tubes. Everything seems put together. It's leaking oil, and looking in back of the intake I see some oil next to the distributor, so I suspect it needs a gasket.

Here we go with the codes-

----------

These are the codes I'm getting:

PO300 -Engine Misfire Detected

P0452 -Fuel Tank Pressure (FTP) Sensor Circuit Low Voltage

PO463 -Fuel Level Sensor 1 Circuit High Voltage

P0174 -Fuel Trim System Lean Bank 2

PO401 -Exhaust Gas Recirculation (EGR) Flow Insufficient

P1153 -HO2S Insufficient Switching Bank 2 Sensor 1

----------

If someone could lead me in the right direction, it would be great. I'm ordering some tubing to patch up my vent to canister line and I'll go from there. Thanks in advance!

98 K1500 ext cab, 5.7 Vortec.

Background of myself, I own a truck identical to it that I rebuilt a lot of. No schooling, self-educated mechanic with fairly good knowledge of the GMT400.

Now on to the truck... I just bought it a week ago. It runs a rough idle, smells rich, and has noticeable misfires. Looking around, I notice a new nylon main fuel line from the tank to the engine bay. The tubes going into the injectors look newer as well. I can tell the evap tubes have been messed with, because the upper one isn't routed the way it should be around the upper rad hose. The lower tube looks to have been replaced. Looking back on the driver side frame rail, I notice the fuel vent tube has been cut out, from the drivers door to about 1ft before it becomes rubber near the tank, so there is no vapor going into the evap canister. I have a feeling this isn't my main issue, but then again I'm not a pro. The previous owner said he just installed a new cap and rotor, and I know he did (or at least someone did), because it's black, while the rest of the distributor is still the stock gray color. He said he [thinks] it needs a new ignition coil. I've already replaced the PCV valve because it was rattling while running, and I thought there was a long shot that might've been what I needed, but of course not.

I used my Bluetooth scanner with Dashcommand, and found lots of misfires. A little on bank one, but a LOT on all of my even numbered cylinders, which I found interesting.

Since my other truck and engine are identical in model and year, I plan on swapping coil units to see if that's the case, but I'm having my doubts. I don't want to just throw parts at it based on personal "hunches", so I came here for help. I've turned to this forum so many times, and to be honest, I would not have been able to complete a LOT of projects on my build, if it wasn't for this great community. Anyway, enough of the sappy crap.

I just don't know where to start. I do know it's getting too much air and not enough fuel. I checked all air connections and tubes. Everything seems put together. It's leaking oil, and looking in back of the intake I see some oil next to the distributor, so I suspect it needs a gasket.

Here we go with the codes-

----------

These are the codes I'm getting:

PO300 -Engine Misfire Detected

P0452 -Fuel Tank Pressure (FTP) Sensor Circuit Low Voltage

PO463 -Fuel Level Sensor 1 Circuit High Voltage

P0174 -Fuel Trim System Lean Bank 2

PO401 -Exhaust Gas Recirculation (EGR) Flow Insufficient

P1153 -HO2S Insufficient Switching Bank 2 Sensor 1

----------

If someone could lead me in the right direction, it would be great. I'm ordering some tubing to patch up my vent to canister line and I'll go from there. Thanks in advance!

You must be registered for see images attach

You must be registered for see images attach

Last edited: