The only small issue I’m having is that 6 out of 10 times when I go to start it, it doesn’t immediately fire on the FIRST key turn. It will crank as long as I hold the key engaged but not fire. (Not a fuel pressure issue) If it doesn’t fire in the first 2 seconds or so I can turn the key back one position then immediately re-engage the starter and it pops right off. It’s very strange. The other 4 out of 10 times, it busts right off.

Greetings Cudajeff,

Welcome to the GMT400 forum. Your project is so clean, a pleasure to view, and your engine

bay looks like it was a factory installation.

****

As for your random 'always cranks, but intermittently no starts...but always starts on the 2nd try'

tells me that you are close, but not quite right on a couple of signals. Given the age and matching

condition of a typical/tired GMT400, a flaky no start is usually traced back to a fuel delivery system

on the edge. But it looks like your truck's fuel delivery system is in new condition, with 60 psi reliably available.

Problem Description / Background theory for intermittent No Start, non fuel delivery related (Engine <> 0411 synchronization)

So the root cause may be a subtle electrical timing issue. For example, a phasing error between 2 signals

that, depending on where the engine stops after the previous previous drive, allows the computer to

figure out the proper relationship between the 2 signals. Or not. Since where the engine stops is

random/unpredictable, this would explain the random nature of the failure.

But it always works on the 2nd try, because spinning the engine, no start, and then having it stop means

that the engine has stopped (and the accompanying physical position reluctors) in a different position than

where the engine was positioned pre-crank the first time, again allowing your computer to sort

out the 'slightly wonky' signal relationship once again. This would plausibly explain why the 2nd start is always successful.

Specific sensors involved in communicating exact engine position to 0411

On our modern EFI systems, the tighter the synchronization between engine & computer the better the

system will interoperate. Cleaner emissions, better dynamics/more responsive to the driver, etc.

The CKP (CranK Position) sensor generates the primary positional signal that the entire timing relationship

between the microsecond-long CPU cycles and the millisecond-long duration engine cycles is built upon.

The name of the CKP signal in the FSMs is the "Reference" signal. And if our engines were designed to

accomplish an entire functional cycle in only 1 360° crankshaft revolution, then all we would need for the

0411 to be completely synchronized to the exact position of the engine would *only* be the CKP sensor.

However, as we all know our 4 stroke engines require 720° of crank rotation, so in order to figure out exactly

where our engine is in terms of which specific cylinder is next to fire, etc., this is the value-added by adding

a CMP (CaM Position) sensor to the 1/2 engine speed camshaft.

And since we now have 2 individual sensors, the phasing between the 2 becomes very important. (!)

Are there any examples out there where a LS <> 0411 suffered the exact same intermittent starting...and the solution is shared?

So with this problem description I went out on the Interwebs and poked around a bit. There were so

many promising threads that eventually petered out and were abandoned before the solution was shared. :-(

But after a few false starts I was reading a thread where an engine was swapped in and the owner wrote the following:

"When it starts, it does so instantly and runs great. No problems no codes. But random if you try and start it, theres a chance it just will turn over over and never actually run. If you stop trying to crank it then immediately try again it fires up no problem. Everyone and internet says its the can sensor but no one reads about the application. This is a gen 4 motor with gen3 24x crank, with a ls2 timing set and from can position sensor. I read on the internet that this should be easy and worry free. But before putting this refreshed engine in the Tahoe started every time."

So the problem description was almost identical. The good news is that the thread delivered the goods:

The solution was shared in reply #4 to the above. Reversing the signal wires from the CMP sensor was the fix.

Although I'm unfamiliar with the exact shape of this specific sensor's signal output, as an old scope dope I *do*

know that an 'upside down' signal can cause enough of a timing change (phasing error) that it could make it

harder for the computer to determine exactly where in the 720° cycle the engine is positioned.

And no doubt, driven by the need for safety in all possible scenarios that owners can come up with, one of the

architectural rules of this system is that the computer won't fire the injectors until it knows exactly where the

engine is. (!)

****

Apologies for taking so long to set the table. But I'm hoping all this will set you up to be able to follow the

logic behind the reported fix:

p01 0411 using front cam position sensor - LS1TECH - Camaro and Firebird Forum Discussion

PCM Diagnostics & Tuning - p01 0411 using front cam position sensor - I have a gen 3 2001 factory Tahoe 5.3, and the motor was replaced with a 5.3 with a front can sensor cover. The crank is 24x and the cam gear is 1x/factory ls2. I know about swapping two wires on the cam sensor harness to get...

ls1tech.com

****

Disclaimer: There's no guarantee that this is the root cause of your specific problem. But I think that double-checking

the wiring between these 2 critical synchronization sensors and the 0411 would be the next logical step. And if the

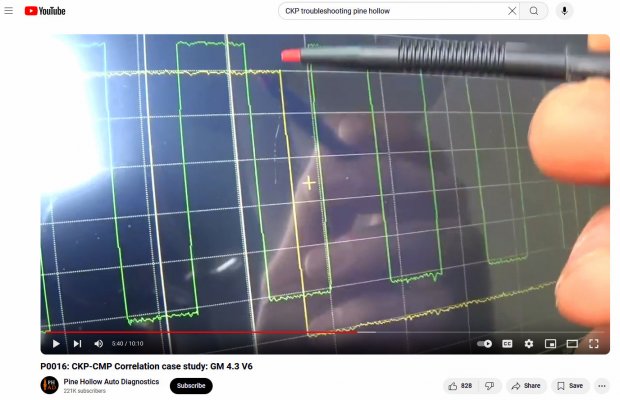

color coding of the wiring checks out 100%, I think actually scoping the signals will be the next step. (Who knows,

maybe a simple reseating of these connectors will cure a marginal output, voltage-wise?) But I can guess all day

about what's just on the edge with the signal integrity between these 2 sensors and the 0411. Timing, voltage level,

excess noise on top of the signal -- with an o-scope this is where the guessing stops and the knowing starts. :0)

Best of luck. And once your discover the fix, please be sure to come back to this thread and share the solution.

Cheers --

Last edited: