You mean a leak down test? What is a pressure test? And why would both heads need to be done apart from I guess it's the right thing to do since it over heated..... I'm just asking but, shouldn't they be able to tell you if the other head gasket is good or not? Or even tell you which cylinder the bad one is leaking at?

Jeez...what if they get into it and the head/s aren't good?

The

leak down test is primarily focused on troubleshooting where our air pump is losing

it's combustion chamber and/or bore seal. On high mileage engines, was the Intake valve bent by

#1 son's money downshift floating the valves last Saturday night? Exhaust valve burnt from too

many hard charges up the mountain pass? Piston rings have lost their mojo due to barrel-shaped

bore wear making them cycle in & out with every stroke? Or were they subjected to a bad overheat

and have now lost their spring tension needed in order to push against the bore?

That's the primary focus. But when you are putting ~100 psi into the chamber, if you take Schurkey's

advice and also remove the radiator cap, IF you have a leak between the combustion chamber under test

and the cooling system, then you will see bubbles in the coolant and no doubt see some related percentage

of pressure loss on the leakdown tester. (Keep in mind that we're pressurizing from combustion chamber out

through the head gasket to the surrounding cooling system.)

****

As for the

pressure test, on the car this is done by removing the radiator cap and installing some test gear

which allows us to pressurize the cooling system to it's normal running pressure (~12-15 psi for our stuff)

and then monitor to see if we lose pressure over time. A really right engine/cooling system will hold this

pressure rock steady overnight with no loss. A slow seep may take an hour to show. Note: A stone cold

motor may leak slowly, but seal at operational temps. (due to expansion giving us more clamping action.) It's

even possible for a cold engine to be leak-free, but lose coolant at temp. (Think crack spreading with temp.)

Just like anything else, gross errors are easier to troubleshoot than weeps/seeps. And you need to think

through what you are doing, for water is even stronger than the General's connecting rods. (!) In other

words, if you are troubleshooting a suspected head gasket failure and the mill is using a lot of coolant,

then you should pull all 8 plugs before the test -- this way, if you happen to push more than a combustion

chamber's worth of coolant into a bad cylinder, at least you won't cause a hydrostatic lock and bend spendy

parts. (Also, the failing cylinder will self-identify when the coolant comes squirting out of the spark plug hole.)

Normally I'm not an absolutist about anything on a vehicle as old as a GMT400, but in this case

any coolant usage

has to be at the very least fully understood, with the mindset of fixing it asap. (Unless you never drive your

GMT400 any farther than you mind walking home. :0)

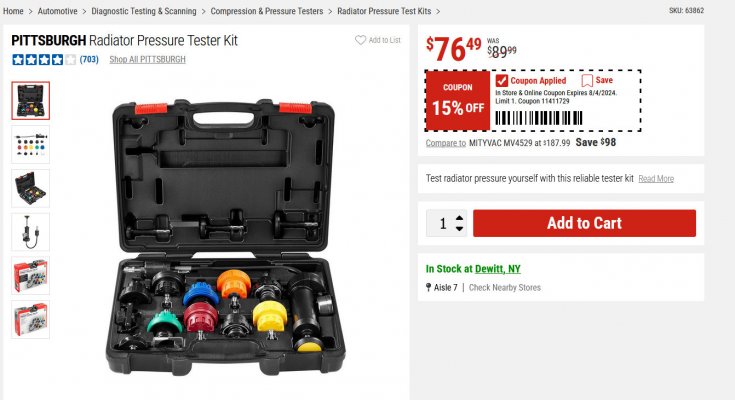

For what it's worth, I've attached a hobbyist-level pressure tester to put a pic to the pressure tester phrase.

Stant & OTC are the next step up for anyone doing this kind of troubleshooting for a living. The only problem

with them is that they ala carte the adapters, so it's gets pretty spendy in a hurry if you have a fleet of dissimilar

vehicles.

****

Last but not least, depending upon the specific head gasket failure we can observe differing symptoms:

You must be registered for see images attach

* Combustion pressure into water jacket = overpressurized cooling system + fails HC in coolant testing.

* Cooling system into combustion chamber = steam cleaned spark plug(s) & combustion chamber(s). Also white smoke out of exhaust.

* Cooling system into lifter valley = mousse for oil. (If engine hasn't been run, water may show first, followed by oil when draining the oil pan.)

* Crack in exhaust port = white smoke in exhaust but no signs of wrongness on the spark plugs. Engine may run fine, for error is post combustion chamber.

* Assembly error (no sealant on head bolts that thread into the block where they are exposed to the water jacket) = coolant metered into combustion chamber.

Note: One difference between a leak down test and a pressure test is that the leak down test is higher pressure, but

also only stresses one cylinder at a time. (Some people only leakdown test the weaker cylinders discovered during

the compression test, so while they may find a burnt exhaust valve they may also miss a coolant leakage issue

by short-cutting the test process.)

On the other hand, a cooling system pressure check tests all cylinders in parallel, albeit with only ~15 psi of pressure.

(And keeping in mind hot fail vs cold fail scenarios as discussed earlier.)

So there are advantages & disadvantages to each of the 3 tests we have in our mechanical troubleshooting arsenal.

****

Obviously if you read between the lines I've worked on a lot of tired engines for myself, friends & family members.

Back when I was learning the ropes I was changing plenty of head gaskets using the Ready, Fire, Aim methodology.

If I was lucky the head gasket swap would work and I was a hero.

But every so often the problem would return after all that time/money/effort spent, and I would subsequently go

from Hero to Zero. :-( And after hob-nobbing with the Elders, I was taught that the more I understood the

problem *before* I open up the engine the better for all involved.

Compression test > leakdown test > cooling system pressure test are all tools that help the DIY mechanic

tighten up the problem definition prior to major surgery in order to fix a coolant leak and/or persistent overheat

while spending only the necessary money to do so.

And also help you determine if the valves are healthy enough that all we need to do is a head gasket, or should we

really get a valve job done as well 'while we are there'. :0)

Hope this comes across as a sensical explanation.

May your overflow tank always return to the same exact spot overnight.

Cheers --