EarthRocker82

Newbie

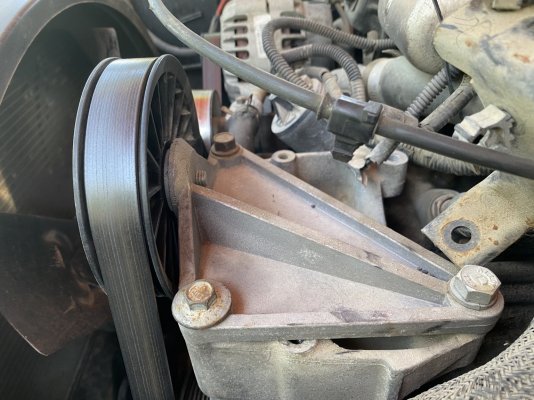

Hi all, new guy here so forgive me if this has been brought up before. I’ve had my truck for about a year now, got it after my father-in-law passed, and am wanting to fix an annoying issue. The truck at one point had the AC compressor deleted due to it probably locking up and had a dummy pulley put in place. The problem is that pulley squeaks like hell and no amount of spray lube on the bearings will get it to stop. Think 5 mins then squealing again. Tried two different sized pulleys with the same result. I’m wondering if there is a shorter belt that can be put on to just bypass the AC location altogether? If so, anyone have a part #? Thanks in advance!