Afternoon gents,

My buddies '98 will barely start after a new fuel pump, fuel filter, and TPS sensor.

I have the following codes,

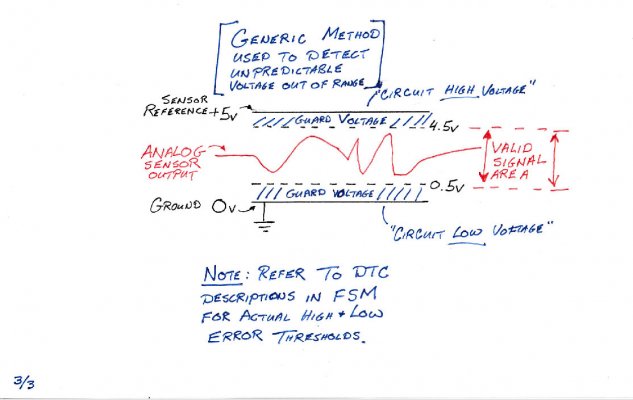

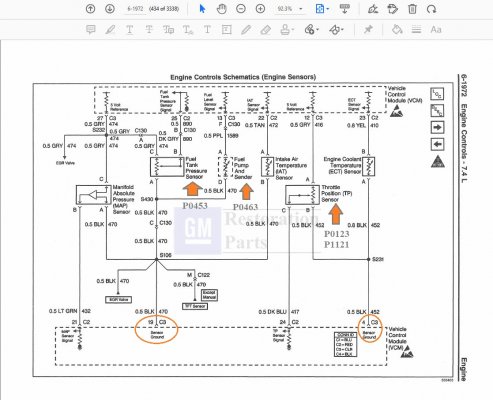

P0123 Throttle Position Sensor (TPS) circuit high voltage

P0453 Fuel Tank Pressure (FTP) sensor circuit high voltage

P0463 Fuel Level sensor circuit high voltage

P0560 System Voltage

P1121 Throttle Position Sensor (TPS) circuit intermittent high voltage

So he replaced the fuel pump, TPS, Fuel filter and still has a very struggling start, that eventually lead to no start, sometimes it will fire for a few seconds then struggle and die.

He then ended up having no fire at all, and I used my habor freight master fuel test kit, and found zero pressure.

Now I have a Autel Maxicheck MX900 and I repaired another buddies '05 tahoe, using it. It's very useful. I commanded his fuel pump on, and found the pressure to slowly decrease. I also use alldata, and the procedure called out that it should hold pressure. We replaced the fuel pump, and it ran alot better and held pressure at the fuel feed line, but still dropped pressure at the rail. Alldata called out for a fuel injector test next for that. It still had a slight miss, and sometimes hard start. Following Alldata, I removed the intake manifold, and tested each injector to find #5 sputtering. We replaced that and not a single issue since. My reason for explaining this is that, my scan tool cannot command the fuel pump on, on this '98. It gives me an error "OUT OF LIMITS RANGE" so I don't know if thats related but there it is.

We dropped the fuel tank, and removed the pump. I reconnected the two connectors, and had him turn the key, no wine, nothing. So we returned it for another, thinking it was DOA or faulty. Then tested the new unit again outside the tank (for a split second) and it works, i can audibly here it running. We then re-installed the tank.

Well now it gets weird. I hooked up my fuel gauge, and I get 10psi KOEO, and it jumps to 55 - 65 when the key is off, and then instantly starts to drop pressure. THEN, sometimes when we cycle the key, I get nothing. To check and see if the pump is working, I removed the fuel filter, and the same process occurs, sometimes I get fuel out of the line, and sometimes I don't when he cycles the key.

I'm going to follow Alldata's procedure for fuel test to a T tomorrow. I ususally just hook one line to a gauge with no relief valve and check that way, but it calls out to remove the relay, remove the fuel pressure, cycle the key, then install the gauge set, cycle the key, and remove the air, the cycle again to test. (Attached image)

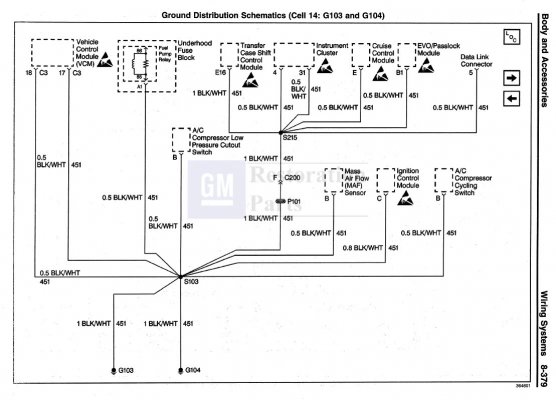

I'm starting to think he has a wiring issue, since I cannot command the fuel pump on with my MX900.

Any thoughts or insight would be very very much appreciated. Thanks guys

My buddies '98 will barely start after a new fuel pump, fuel filter, and TPS sensor.

I have the following codes,

P0123 Throttle Position Sensor (TPS) circuit high voltage

P0453 Fuel Tank Pressure (FTP) sensor circuit high voltage

P0463 Fuel Level sensor circuit high voltage

P0560 System Voltage

P1121 Throttle Position Sensor (TPS) circuit intermittent high voltage

So he replaced the fuel pump, TPS, Fuel filter and still has a very struggling start, that eventually lead to no start, sometimes it will fire for a few seconds then struggle and die.

He then ended up having no fire at all, and I used my habor freight master fuel test kit, and found zero pressure.

Now I have a Autel Maxicheck MX900 and I repaired another buddies '05 tahoe, using it. It's very useful. I commanded his fuel pump on, and found the pressure to slowly decrease. I also use alldata, and the procedure called out that it should hold pressure. We replaced the fuel pump, and it ran alot better and held pressure at the fuel feed line, but still dropped pressure at the rail. Alldata called out for a fuel injector test next for that. It still had a slight miss, and sometimes hard start. Following Alldata, I removed the intake manifold, and tested each injector to find #5 sputtering. We replaced that and not a single issue since. My reason for explaining this is that, my scan tool cannot command the fuel pump on, on this '98. It gives me an error "OUT OF LIMITS RANGE" so I don't know if thats related but there it is.

We dropped the fuel tank, and removed the pump. I reconnected the two connectors, and had him turn the key, no wine, nothing. So we returned it for another, thinking it was DOA or faulty. Then tested the new unit again outside the tank (for a split second) and it works, i can audibly here it running. We then re-installed the tank.

Well now it gets weird. I hooked up my fuel gauge, and I get 10psi KOEO, and it jumps to 55 - 65 when the key is off, and then instantly starts to drop pressure. THEN, sometimes when we cycle the key, I get nothing. To check and see if the pump is working, I removed the fuel filter, and the same process occurs, sometimes I get fuel out of the line, and sometimes I don't when he cycles the key.

I'm going to follow Alldata's procedure for fuel test to a T tomorrow. I ususally just hook one line to a gauge with no relief valve and check that way, but it calls out to remove the relay, remove the fuel pressure, cycle the key, then install the gauge set, cycle the key, and remove the air, the cycle again to test. (Attached image)

You must be registered for see images attach

I'm starting to think he has a wiring issue, since I cannot command the fuel pump on with my MX900.

Any thoughts or insight would be very very much appreciated. Thanks guys