You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2000 Z71 seat track loose

- Thread starter JohnZ71

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

John DeWitt

Newbie

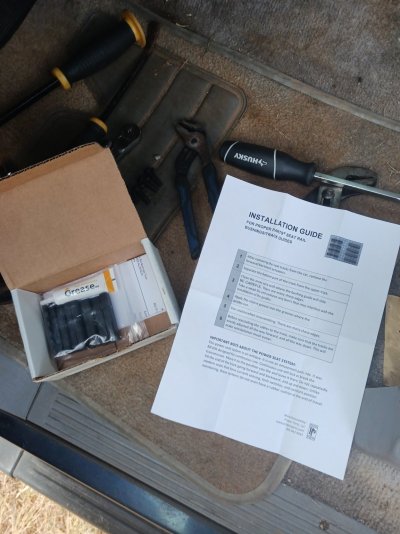

Parts are in, sorry for the delay in getting back to it. Between work & rain on days off this like so many other projects gets pushed back. Currently standing here trying to figure out how to disassemble the rails & track. Looks like this will go easier if I unbolt the assembly from the body. I'll try to document every step as there doesn't appear in my searching to be any information on this process.

Attachments

John DeWitt

Newbie

FINALLY getting back to this project, sitting here letting the degreaser eat away the old thick grease from the tracks while I submit what I've got so far today.

Step 1: Remove both of the rivets from the front of the tracks, there is 1 on each side. I've found cutting the bottom alone isn't enough as it's expanded on the bottom side, thus risking marring up the soft aluminum inside the track line. I then could punch out the steel center piece of the rivet easily. I had attempted to drill out the rivet initially, however the rivet would begin spinning with the bit. So, after removing the bottom portion of the rivet with a small gap of material left, I then cut an x pattern into the head as seen in the pictures. This then allows for breaking off of the rivet head into 4 sections with a flat head/pry bar & a hammer. These rivets will need to come out completely as they will stop the tracks from sliding apart. Removing these rivets was for me easier with the track system still bolted to the body.

Step 1: Remove both of the rivets from the front of the tracks, there is 1 on each side. I've found cutting the bottom alone isn't enough as it's expanded on the bottom side, thus risking marring up the soft aluminum inside the track line. I then could punch out the steel center piece of the rivet easily. I had attempted to drill out the rivet initially, however the rivet would begin spinning with the bit. So, after removing the bottom portion of the rivet with a small gap of material left, I then cut an x pattern into the head as seen in the pictures. This then allows for breaking off of the rivet head into 4 sections with a flat head/pry bar & a hammer. These rivets will need to come out completely as they will stop the tracks from sliding apart. Removing these rivets was for me easier with the track system still bolted to the body.

Attachments

John DeWitt

Newbie

Step 2: Remove the track system from the body, all held in by 4 bolts to the body. 2 Phillips head screws hold the side panel on, 1 screw in front & 1 in back. Remove this to gain access to the door side bolts. An impact gun, swivel adaptor, & 15mm make quick easy work of this. God Bless if you have to use a ratchet or wrench. Go ahead & get some shop towels, brake cleaner, a good heavy duty degreaser & get comfortable for the next step.

Attachments

John DeWitt

Newbie

Step 3: This is where I'm currently at as I type this. In order to separate the 2 tracks, you will need to remove the 2 bolts on each side off the top of the gear transition "box". These are 10mm, just make sure your seat is set at its highest seating level so you access these bolts. If not, plug it back up (like I had to, mine was the black connector) & quickly adjust. Removal of the passenger side is simple after taking out the odd tipped bolts, the driver side you must remove the 1 12mm bolt holding the mounting plate for the motors. This gives you enough play to pull the gear "box" up & out of the track. After doing so, just lift up on the electric motor carefully while also lifting up the driver side gear "box", doing so together helps reduce stress on old components. After both "boxes" are popped out, you can now put a foot on the bottomg track cross support while holding the upper track system at the side. Push with your foot, use you hands to pull while easily guiding both sides evenly. Remove in the direction of the rivets you cut. If there's anything left of the old nylon bushing, expect them to fall out. Oherwise you can remove what pieces are still holding after seperation. Continue until both tracks are separated, carefully lay the upper track down, don't stress the cables as that's all that's holding the 2 sides together now. Get to cleaning!

Attachments

Last edited:

John DeWitt

Newbie

John DeWitt

Newbie

So glad I found this and thank you for this write up.FINALLY getting back to this project, sitting here letting the degreaser eat away the old thick grease from the tracks while I submit what I've got so far today.

Step 1: Remove both of the rivets from the front of the tracks, there is 1 on each side. I've found cutting the bottom alone isn't enough as it's expanded on the bottom side, thus risking marring up the soft aluminum inside the track line. I then could punch out the steel center piece of the rivet easily. I had attempted to drill out the rivet initially, however the rivet would begin spinning with the bit. So, after removing the bottom portion of the rivet with a small gap of material left, I then cut an x pattern into the head as seen in the pictures. This then allows for breaking off of the rivet head into 4 sections with a flat head/pry bar & a hammer. These rivets will need to come out completely as they will stop the tracks from sliding apart. Removing these rivets was for me easier with the track system still bolted to the body.

JohnZ71

Z71 Tahoe Enjoyer

Did you get everything back together?Additional pictures

Could you tell a difference in the seat? Less slop, etc.

John DeWitt

Newbie

Step 4: (Sorry for the delayed response on this. I did get it all back together same day but had to immediately hit the road afterwards).

Reassembly is a bit tricky, just have a hard level surface to evenly push both sides of the upper & lower rails back together & it won't be so difficult. Getting some of the bushings to snap in took a little trial & error, they have grooves they have to fit precisely in or they wont take at all. With some moderate pressure, & exact guidance they snapped in place. These bushings are tight, but well made & have absolutely no slop. With the tracks cleaned, I applied the grease supplied with the new bushings. However, I also opted to add additional lubrication so as to help prolong the life of not just the bushings but the motors also. During reassembly, I discovered that I accidently pulled out one of the cables from the actuator that raises the seat. I had to pull the tracks back apart in order to get them back together as there wasn't enough flexibility w/o fear of something snapping the cable, so keep an eye of caution out for that. Once back together, I worked the tracks back & forth with each time pushing the excess lube back into the bushings path of travel. Several times of doing this made the track movement easier & easier. The "high performance" grease supplied had separated in the tube, parts coming out white & other clear. The additional grease I used was bought from Harbor Freight, it's what I use in the bearings & slides for my kids toys, wagons, strollers, etc. Damn good stuff, safe for the family & great for this application (I even greased the gears). Once everything was correctly assembled, I used the little peep hole in the upper track to line up the hole in the bottom track as pictured. This way, I not only know that the bolt holes are lined up but so are the tracks evenly with the other side thus preventing any off center torque from misaligned tracks. This also let the gear box slip right in & the gear & gear track mate back easily. Press the gear boxes back in, put bolts in, bolt everything back to the body, plug up, test movement, find some bolts to put back in place of the rivet holes, bolt down the seat, side panel & done. Now, ive had this 99 Suburban for 6 years, never have I felt so sturdy in that time driving it as I do now. It's tighter than a roller coaster harness & has no give when adjusting myself into the seat. The level of feel for the road this little project has added is real. It has amazed me to learn just how much of a disconnect from the vehicles travel I had been missing. In a few ways, I'm having to relearn the feel of my Suburban. Additional pictures to follow shortly.

Reassembly is a bit tricky, just have a hard level surface to evenly push both sides of the upper & lower rails back together & it won't be so difficult. Getting some of the bushings to snap in took a little trial & error, they have grooves they have to fit precisely in or they wont take at all. With some moderate pressure, & exact guidance they snapped in place. These bushings are tight, but well made & have absolutely no slop. With the tracks cleaned, I applied the grease supplied with the new bushings. However, I also opted to add additional lubrication so as to help prolong the life of not just the bushings but the motors also. During reassembly, I discovered that I accidently pulled out one of the cables from the actuator that raises the seat. I had to pull the tracks back apart in order to get them back together as there wasn't enough flexibility w/o fear of something snapping the cable, so keep an eye of caution out for that. Once back together, I worked the tracks back & forth with each time pushing the excess lube back into the bushings path of travel. Several times of doing this made the track movement easier & easier. The "high performance" grease supplied had separated in the tube, parts coming out white & other clear. The additional grease I used was bought from Harbor Freight, it's what I use in the bearings & slides for my kids toys, wagons, strollers, etc. Damn good stuff, safe for the family & great for this application (I even greased the gears). Once everything was correctly assembled, I used the little peep hole in the upper track to line up the hole in the bottom track as pictured. This way, I not only know that the bolt holes are lined up but so are the tracks evenly with the other side thus preventing any off center torque from misaligned tracks. This also let the gear box slip right in & the gear & gear track mate back easily. Press the gear boxes back in, put bolts in, bolt everything back to the body, plug up, test movement, find some bolts to put back in place of the rivet holes, bolt down the seat, side panel & done. Now, ive had this 99 Suburban for 6 years, never have I felt so sturdy in that time driving it as I do now. It's tighter than a roller coaster harness & has no give when adjusting myself into the seat. The level of feel for the road this little project has added is real. It has amazed me to learn just how much of a disconnect from the vehicles travel I had been missing. In a few ways, I'm having to relearn the feel of my Suburban. Additional pictures to follow shortly.

Similar threads

- Replies

- 6

- Views

- 883

- Replies

- 1

- Views

- 171

Members online

- JohnZ71

- BuiltToWork

- 96c2500217

- someotherguy

- Johnfred

- JoeJoe1993

- Zkull13

- Erik the Awful

- Pinger

- caw_86

- White96k2500

- TonyM

- 454cid

- Turboturro

- BNielsen

- stpat

- fancyTBI

- mohrtrouble88

- termite

- 95YardArt

- digthis

- devilino

- Poondart

- jvick9494

- luvmyjim

- Billnieters

- megafan0258

- kxvobs

- Supercharged111

- Rolly58

- micha912

- OlSmokie

- Green1998

- R_Batesk1500

- Scooterwrench

- 89RCLB

- b454rat

- Dravec

- 62barsoom

- n2xlr8n

- caminonut

Total: 1,566 (members: 45, guests: 1,521)