Anchor-Enthusiast

Newbie

Thank you for the thorough and concise response. That makes perfect sense to me. I will grab the pressure gauge you recommended.Greetings Anchor-Enthusiast,

The overall success of a sharp troubleshooter is due as much to the quality/accuracy of their

test equipment in addition to having a working knowledge of the subsystem they are working on.

Schurkey is making a very valid point about trying to get actionable info out of a 0-100 psi

fuel pressure gauge on a 'low-pressure design' TBI system. (I define 'actionable' as data that's

reliable enough that I'm willing to change parts because of what I'm being shown.)

For what it's worth, to me this would be the (affordable) gold standard in the 0-15 PSI fuel pressure

tester:

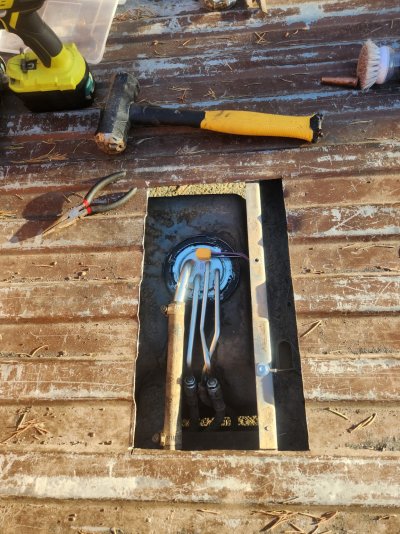

You must be registered for see images attach

Here's the current Summit listing for this ~$37 + shipping gauge: (OTC vacuum/pressure test gauge)

NOTE: I would be willing to use a cheaper gauge, but ONLY after I could test it side-by-side with one of these

and verify that it agreed. (Same thing for a bang-around daily use cheap multimeter -- only after it's proven

to agree with my reference-use Fluke. :0)

Charitably speaking, that's a well-meaning but misleading explanation. I wouldn't recommend using that line of reasoning

while troubleshooting your fuel delivery subsystem. I'll try to substitute a concise overview of what you want to look for.

There are 2 variables that we need to be thinking about in our fuel system. The first is how high the pressure climbs to,

and the second is how much volume that the fuel pump is capable of delivering to the TBI. For example, even a good pump

can be constrained by a dirty inlet strainer, similar to a human sucking on a smashed soda straw.

Or, assuming that the inlet sock is good, the fuel filter on the pressure side between the pump outlet and the TBI nozzles

is partially plugged. Thinking about it, with the fuel pump running while the engine is stopped, you might measure 12 psi before the

filter as well as the same 12 psi after the filter. Because there is no flow (volume) ...you are simply measuring the 'deadhead' (no flow)

pressure that Schurkey has referenced.

But let's say that you start the truck, and idling there is now a 2 psi drop across the partially-plugged filter. A bit oversimplified,

but having a larger vs smaller diameter hose between the filter & TBI nozzles isn't going to make a difference at what the

injectors see/feel.

Taking this thought experiment a little further, I'm going to state that at 10 psi (nozzle) the truck will idle OK. And it will

drive during light throttle/light loads OK. But with the more demand (longer injector pulsing) we could watch the pressure

drop in response, and quickly we'll reach a point where insufficient fuel will be delivered to the air rushing past, and the

bucking/stalling will begin. (NOTE: If we were to check the fuel pressure *before* the fuel filter, no doubt it would remain

steady. But the TBI nozzles don't care about what's going on between the fuel pump & plugged filter. They only care

about the fuel pressure at the input to the injectors. (!)

In this case, simply changing the inline fuel filter will remove the pressure drop/fuel flow bottleneck across the new filter,

and (assuming a good pump) the pressure will always be more than needed for the FPR to be able to hold the pressure

steady at the nozzles, no matter how hight or low the engine demand is.

****

The reason why I dragged us through the above is that a static fuel pressure check alone is just a partial go/no-go answer.

When I see fuel pressure, this tells me that I at least have some electricity being sent down to the pump. But in order to

figure out IF we have enough fuel pressure to cover all possible demands, the best answer is to (temporarily) install a Tee that

allows me to monitor the fuel pressure while the vehicle is being operated, preferably under the same loads as when you

are doing the daily driver thing. NOTE: Since outboard fuel volume test equipment is spendy, we instead use a fuel

pressure gauge AND monitor the fuel trims reported by the computer.

*** CAUTION CAUTION CAUTION ***

It goes without saying that safely testing the delivery pressure of a flammable liquid in the vicinity of a hot exhaust

system is serious business. This is not a dribbly duct-tape connection & hit the road scenario. Elsewhere in this forum

members have documented some slick ways to safely tee into their fuel delivery system. Deadhead testing a fuel pump

in a cold engine bay is both easy & gives you a go/no-go answer. But in order to observe the system under load is quite

a bit more involved. Be aware. Leak-free test connections and an onboard fire extinguisher is a prudent bare minimum.

****

If I were to guess, I'll bet that Schurkey's mindset is that if your system can only deliver 6 psi before the engine starts

to draw fuel, then it's not going to take too much gas pedal to force a fuel delivery error at the nozzles.

Apologies for the length, but given what the helpful NAPA dude was telling you, I wanted to try to help explain why we

need to worry about pressure -and- end-to-end volume delivery capability, from inlet sock > fuel pump > inline fuel filter > TBI nozzles.

And a good quality 15 psi fuel gauge tee'd in (plus fuel trim data from the computer) will tell you everything that you need

to know. EDIT: If a trustworthy gauge still tells you 6 psi, then a new pump (and/or fresh wiring) is in order since you've

already tried a new filter. Fingers crossed that the new gauge shows you 12-15 PSI at the input to the TBI, and that the

MAP sensor was 100% of your original driveability issue.

Best of luck keeping that GMT400 on the road and earning it's keep.

Here's another question, I'm having issues finding a live data obd1 scan tool. I can find several models online, but all of them say "discontinued" or "currently unavailable".

Do you have any recommendations for a model and/or a vendor for such a device?

I also appreciate all of the VERY helpful responses from everyone, I'm not a novice in mechanics in general, but I am absolutely a novice when it comes to these tbi systems. This is the first time I've ever torn into one. Things seemed confusing at first, but after a few weeks of reading through these forums I've been pleasantly surprised by how simple the system actually is. So thank you all again for the wealth of information you've made available to all of us.

One last question, I have a stage one chip on the way from Brian over at Harris racing and he has programmed the EGR delete into the chip, once I have that chip and block off plate installed, that's the end of the egr system, right? And for full transparency, i did not remove the EGR system, the previous owner did it in an ill-conceived attempt at gaining more power. I'm just trying to decide whether to finish the delete, or to put the EGR system back together in it's OEM configuration.

Thanks again,

-J